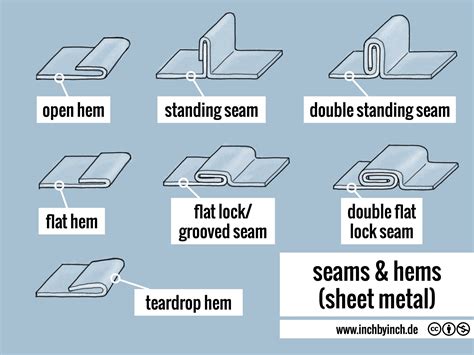

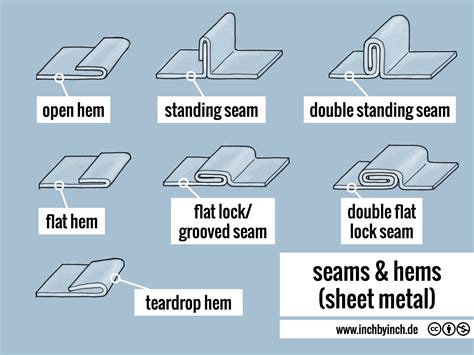

folded seam sheet metal The difference between them is that hemming involves folding sheet metal so that the two layers are flush with each, whereas seaming . Westech Metal Fabrication Inc located at 3420 E St, San Diego, CA 92102 - reviews, ratings, hours, phone number, directions, and more.

0 · types of sheet metal seams

1 · sheet metal side seam

2 · sheet metal seams pdf

3 · sheet metal seams explained

4 · sheet metal seams diagram

5 · sheet metal seam sizes

6 · sheet metal seam joints

7 · sheet metal seam

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

types of sheet metal seams

customized brass metal stamping parts

sheet metal side seam

The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a . Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork. A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a seal that isolates one side of the sheets from the other. As a result, seaming finds .

The difference between them is that hemming involves folding sheet metal so that the two layers are flush with each, whereas seaming .Folded Seam. A folded seam is made by folding the edges of both ends of the metal and hooking the folds together before pounding flat with a mallet and soldering. Folded seams are simple, . From riveting and welding to folding and soldering, sheet metal joints offer an array of techniques and approaches that are critical in achieving the strength, . A seam joint is created by folding and joining the edges of two .

On the ribbon, click Sheet Metal tab Modify panel Corner Seam. Select a model edge on each of two adjacent sheet metal faces. Accept the default seam type or select another of the three seam types. In the Corner Seam dialog box, you can: Use the Face/Edge distance measurement method instead of the defaulted Maximum Gap Distance method.Folding / Seam Closing Tools Sheet metal folding & seam closing tools. UniBieger Drip Edge Bender 420T XL (Code: UNI-420TXL ) £ 495.00. Details Add to Cart. Proven technology in a new format, introducing the Model T XL. .

customized high-end precision sheet metal dezhen manufacturer

This video discusses the different commonly used connection joints found on Sheet Metal Duct work.B&B Sheet Metal’s Series B1301/B1300 presents the same architectural aesthetics as the architectural snap-lockpanels except with structural strength and weather tightness advantage of a mechanically seamed system. . Power seamers and other seamers are available for purchase or rental for all standing seam installation project. Contact B&B .Home » Installation » Custom Work » Flat Seam Roofing. . The panels are made from 18” x 24” sheets, with all four sides folded over, two sides one way and the other two opposite. They are installed with clips that are fastened into the plywood. . Sheridan Sheet Metal Co. 4108 Quebec Ave N. New Hope, MN 55427. P: (763) 537-3686 F .Depending on the basic design, sheet metal projects usually require some form of overlap to hold joins together. The most common seams used in basic sheet metalwork are: The lap seam; The folded seam; The grooved seam. These seams are illustrated in the pictorial sketches and simple developments below.

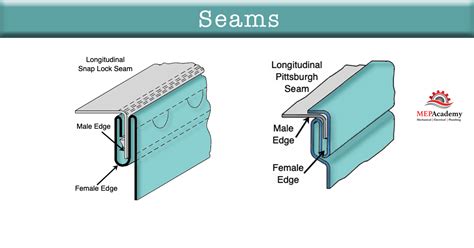

Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.Seam Tools; Sheet Metal + Metal Roofing; Shingle Roofing Tools; Slate Roofing Tools; Siding and Gutter Tools. Gutter Cleaning Products; Gutter Seal; Gutter Tools; . Malco, MBL Sheet Metal Folding Mini Brake Optional Leg Kit . Optional leg kit for Malco MB48A Mini Brake . Price: 5.95. Availability: In Stock. Metal Bending : Our sheet metal folding is designed to effortlessly and precisely bend metal into the desired shapes, the folded seam is formed by permanently joining two half-steels. Two Folding Depths: This bending offers 3/8" and 1" folding depths, catering to various requirements in handling seams, edges, flat bottoms, or driving edges in .

The Malco Drip Edge Folding Tool is available in two lengths with two folding seam depths for making quick and easy bends along the drip edge of standing seam metal roofing! A new 18-inch (46 cm) long Model DEFT1 and improved 24-inch (61 mm) Model DEFT combine to match up with most flat pan standing

Bending, Cutting, Notching, And Folding Standing Seam Metal Roofing Panels. Detailed How To Instructions For Standing Seam Panels At The Eave Ends Of The Roo.

In sheet metal shops, a rollforming machine is used to fold the Pittsburgh seam on one end of a piece of ductwork, for example; this increases productivity while keeping each seam consistently formed on multiple pieces of duct. Manually forming a Pittsburgh seam will result in a joint with the same strength as a rollformed seam, and it does not .

At Metal Cladding Systems we make all our products on a project-based production line. This enables us to remain flexible and responsive to custom design requests and out of the norm project requirements.

Corrosion is a major challenge for sheet metal parts, especially those used in outdoor or harsh environments. Protective coatings like powder coating, galvanization, or anodizing can significantly reduce corrosion.. For .K2 sheet metal seam clamp for Klip-Lok 700 Hi-strength® and Klip-Lok Optima® 700 (Lysaght ™) sheet metal roofing; KingKlip® 700 (Fielders®); Klip-Lok® 406 (Lysaght ™). . Use on copper double folded standing seam metal roofs. The inlay avoids electrochemical corrosion between copper roof and aluminium clamp. Material: stainless steel V2ATraditional European sheet metal cladding, for statement making facades. Batten Seam is one of the oldest and most traditional metal cladding profiles. Not commonly seen in our market, the system is widely used across Europe. . Hi, Is it possible to do sheet metal folding as below photo? . You can get the result you want by using the Corner Seam command from the sheet metal tool bar. By picking overlap or reverse overlap options you can change how the edges will overlap. Red means remove material green means add material.

HVAC Sheet Metal Duct Systems, Module 03213. 5.0 (1 review) . or pipe lock. The seam consists of two folded edges that are hooked together and locked with a grooving machine or hand groover. . First, the short edges of two pieces are turned 180* to form two pockets. The drive is formed from a sperate piece of metal, the edges of which are .

Two folded edges that are hooked together. Standing seam. . the reinforcement cap made of sheet metal called a blind edge. Flat seam. Resembles a standing seam that is bent flat against metal. A flat seam is used to connect long, flat pieces of sheet metal. Coffin lock. Create a smooth outside surface. Usually 1/4 inch, but can be made with .Seams are used to fasten sheet metal sections together having locks, rivets, screw, brazing, or soldering. They can be made by hand, on a brake, or on a bar fold. The type of seam made and the fastening method depends on the tyoe of metal, its thickness, and its fabricating machinery available to the worker. A wide variety of seam types have .Shop Stortz for a first class offering of sheet metal tools. Mechanical Lock Seamers; Power Seamers; Seaming Anvils; . RAU RAU Systems has been manufacturing German made sheet bending and folding tools for roofs and facades for over 60 years. If you have worked with mechanical locking standing seam panels, chances are you have come across the .

Feature:*Brackets for fixing structures for solar, photovoltaic or similar systems to folded sheet metal roofs.*Aluminium standing seam clamp. The screws and washers are made of stainless steel. The clamps are pre-assembled.Details:*Material:aluminum alloy*Color:sliver*Size:45*52mm (as shown in the picture)Package Contents:4pcs Aluminium .Hems and edges are used mainly in architectural sheet-metal work and special projects. . No, false. A clinch lock is based on two folded edges hooked together.* No, false. Shoulder locks provide support for one piece of metal joined to another at right angles. * Yes, true. A standing seam is never riveted, bolted, or button punched.* No, false.

Sheet metal folding & seam closing tools. Rau Double Eaves Edger TSCH EDP106 (Code: TSCH) £ 186.00. Details Add to Cart. Closes eaves edges. Rau Square Seam Folder WFSCH EDP111 (Code: WFSCH) £ 186.00. Details Add to Cart. Closes the single lock standing seam. Rau Twin Square Seam Folder WDF EDP117

When to apply the 4 Common Types of Sheet Metal Hems to your Design 1. Closed hem. Also known as a crushed hem, a closed hem is completely flush (as opposed to an open hem, which allows for a bit of space in the bend).. Closed hems are the most popular type of hem because they’re so easy to make: the sheet metal is simply flattened onto itself.

SHEET METAL FLASHING AND TRIM . PART 1 - GENERAL 1.1 SUMMARY . A. Section includes the following: 1. Metal flashing. 2. Self-adhering flashing. . interlocking folded seam, or blind rivets and sealant. Lap counterflashing joints a minimum of 2 inches and bed with sealant. SECTION 07620

IMS stocks welding products for MIG welding, TIG welding operations, and accessories for welding. Shop helmets, welding apparel, consumables, and more.

folded seam sheet metal|sheet metal seams explained