drawing notes for cnc lathe parts Technical drawings are documents that contain detailed 2D drawings of a part to be manufactured, along with various crucial manufacturing data. These documents ensure the clear and complete communication of the . The eye iron is an essential tool for those in high-level contact sports, including Boxing, MMA, and Kickboxing. Designed to quickly tackle swelling from cuts and bruises, its mechanism revolves around applying concentrated cold pressure directly onto the injury.

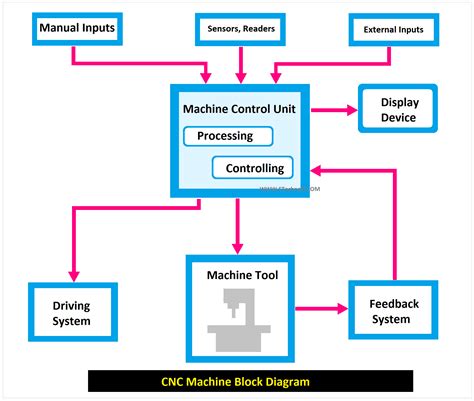

0 · schematic diagram of cnc machine

1 · explain Mcu in cnc

2 · diagram of cnc lathe machine

3 · cnc turning lathe machine

4 · cnc machine labelled diagram

5 · cnc lathe machine specification

6 · cnc lathe headstock

7 · block diagram of cnc machine

Need a connector or lead for your TV setup? We explain what the connectors do, and aim to point you in the right direction. An Aerial Flylead is used to connect from a TV aerial socket on the .

When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis . When drafting a CNC machining drawing, it is essential to include pertinent notes for manufacturers. It helps them to create desired components accurately since it comprises critical information not contained in the .

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine .

Technical drawings are documents that contain detailed 2D drawings of a part to be manufactured, along with various crucial manufacturing data. These documents ensure the clear and complete communication of the . When creating technical drawings for CNC machining, it’s important to include pertinent notes for the manufacturer so they can accurately produce the desired component. Some key information to include in these . The technical drawing for CNC machining is composed of several essential components, including coordinates, title block, isometric view, orthographic views, section views, detail views, and pertinent notes for the .

Preparing a technical drawing for CNC machining requires attention to detail and a methodical approach. Here are seven simple steps to guide you through the process: Step 1: Define the Objective: Clearly understand the .

Manufacturers are trained to quickly identify the part using 2D drawings. It is easier for them to identify major dimensions and critical components of the parts. There are many different.

There are several components that are part of technical drawings. Among the most important components are the title block, the isometric view, the orthographic view, the coordinates, the section view, and the detail view.When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis coordinates should be dimensioned from the face of the .

When drafting a CNC machining drawing, it is essential to include pertinent notes for manufacturers. It helps them to create desired components accurately since it comprises critical information not contained in the blueprints, like required material, tolerance specification, surface finish requirements, and other special instructions.Providing a technical drawing can help you source better parts and even reduce your costs. In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing.Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC. Technical drawings are documents that contain detailed 2D drawings of a part to be manufactured, along with various crucial manufacturing data. These documents ensure the clear and complete communication of the technical requirements of projects between the designer and the .

schematic diagram of cnc machine

When creating technical drawings for CNC machining, it’s important to include pertinent notes for the manufacturer so they can accurately produce the desired component. Some key information to include in these notes includes the required material, surface finish requirements, tolerance specifications, and any special instructions regarding .

explain Mcu in cnc

The technical drawing for CNC machining is composed of several essential components, including coordinates, title block, isometric view, orthographic views, section views, detail views, and pertinent notes for the manufacturer. Preparing a technical drawing for CNC machining requires attention to detail and a methodical approach. Here are seven simple steps to guide you through the process: Step 1: Define the Objective: Clearly understand the purpose of the part and its intended function. Manufacturers are trained to quickly identify the part using 2D drawings. It is easier for them to identify major dimensions and critical components of the parts. There are many different. There are several components that are part of technical drawings. Among the most important components are the title block, the isometric view, the orthographic view, the coordinates, the section view, and the detail view.

When creating a part drawing used to program the CNC lathe, all part diameters must be dimensioned, as well as the starting and ending coordinates for all arcs/radii. All Z-axis coordinates should be dimensioned from the face of the .

When drafting a CNC machining drawing, it is essential to include pertinent notes for manufacturers. It helps them to create desired components accurately since it comprises critical information not contained in the blueprints, like required material, tolerance specification, surface finish requirements, and other special instructions.Providing a technical drawing can help you source better parts and even reduce your costs. In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing.

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

Technical drawings are documents that contain detailed 2D drawings of a part to be manufactured, along with various crucial manufacturing data. These documents ensure the clear and complete communication of the technical requirements of projects between the designer and the . When creating technical drawings for CNC machining, it’s important to include pertinent notes for the manufacturer so they can accurately produce the desired component. Some key information to include in these notes includes the required material, surface finish requirements, tolerance specifications, and any special instructions regarding . The technical drawing for CNC machining is composed of several essential components, including coordinates, title block, isometric view, orthographic views, section views, detail views, and pertinent notes for the manufacturer.

Preparing a technical drawing for CNC machining requires attention to detail and a methodical approach. Here are seven simple steps to guide you through the process: Step 1: Define the Objective: Clearly understand the purpose of the part and its intended function. Manufacturers are trained to quickly identify the part using 2D drawings. It is easier for them to identify major dimensions and critical components of the parts. There are many different.

fence corner brackets for metal t-posts

fiber optic distribution box h.s.code

diagram of cnc lathe machine

In the industry, they call it a structured media enclosure. You would have to find the Coax cable that comes in from your ISP or Cat5e if using DSL and plug it into your modem.

drawing notes for cnc lathe parts|cnc turning lathe machine