drafting sheet metal parts This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad . Empty Watercolor Palette Tins Box Metal Paint Case with Fold Out Palette, Medium Colorful Watercolor Tray Palette with 37 Empty Half Pans and a Watercolor Pen for DIY Travel Watercolor Palette

0 · simple sheet metal drawings

1 · sheet metal layout drawings

2 · sheet metal drawing for practice

3 · sheet metal drafting standards

4 · sheet metal drafting pdf

5 · sheet metal basic drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

$9.99

Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to .

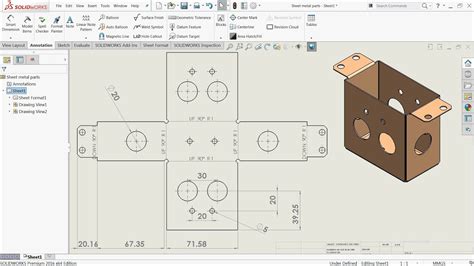

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, .

Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality .

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, . This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad . Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback.A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create.

Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality permits. Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable. Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, finish types, and . This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad benefits.

Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback.Some engineers have difficulties properly designing sheet metal parts for manufacturing. That’s not you, of course (wink-wink). Still, we notice that there are certain issues that frequently appear in models that we’ve been asked to quote. With these issues in mind, we offer this list.In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includesLearn how to design functional and easy to manufacture sheet metal parts regardless of your experience level or industry. what's included. Still not convinced? Here’s a sneak peek so you can see what’s included. Get the Free Guide. Want to learn more? Check out the Five Flute Resources Page for more articles, calculators, and helpful guides.

metal fabrication cedar city utah

A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create. Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection.

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality permits. Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable.

metal fabrication cebu

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, finish types, and . This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad benefits. Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback.Some engineers have difficulties properly designing sheet metal parts for manufacturing. That’s not you, of course (wink-wink). Still, we notice that there are certain issues that frequently appear in models that we’ve been asked to quote. With these issues in mind, we offer this list.

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

simple sheet metal drawings

sheet metal layout drawings

metal fabrication classes grand junction co

15 Amp Outdoor Electrical Outlet Box with On/Off Switch and Indicator Light, 125 Volt NEMA 5-15 Duplex Receptacle, Grounding, IP66 Waterproof Wall Power Socket, Weather and Tamper .

drafting sheet metal parts|simple sheet metal drawings