sheet metal forming processes and applications pdf Chapter 1 Metal Forming Processes in Manufacturing ... 1 1.1 Classification of Manufacturing Processes ... 1 1.2 Characteristics of Manufacturing Processes ... 1 Polycase’s stainless steel electrical boxes are UL Listed to UL 508A, meeting NEMA 1, 2, 4, 4X and 12 ratings and IP65 and IP66 requirements for harsh environments. Manufactured from 304 stainless steel, they’re a top enclosure .

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

ABS IP67 Waterproof Dustproof Electrical Junction Box, with 15A 600V Barrier Terminal Cable Connector, 3 in/3 Out Power Junction Box(3.93*2.67*1.96in)

sheet metal working process pdf

electric dog fence control box

Sheet Metal Forming: Processes and Applications covers all major sheet forming operations including blanking, bending, flanging, deep drawing, stamping, spinning, clinching, and crimping.Chapter 1 Metal Forming Processes in Manufacturing ... 1 1.1 Classification of Manufacturing Processes ... 1 1.2 Characteristics of Manufacturing Processes ... 1rolling of sheet, sheet incremental forming, hydroforming, hydromechanical forming, mechanical calibration, flexible-reconfigurable forming processes and forming methods at elevated .This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all.

In this paper, the literature available on the effect of process parameters on the final product of a sheet metal forming process including drawing, bending and to some extent, .

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .By applying bulk forming processes to sheet metal material the TCRC 73 is providing a significant contribution to the development of forming technologies and thus to the solution of several of .Numerical simulation of metal forming processes, as a component of the virtual manufacturing process, has a very important contribution to the reduction of the lead time. The finite element . This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual .

Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters. Other chapters cover sensors and die materials, which are critical for practical sheet forming applications.

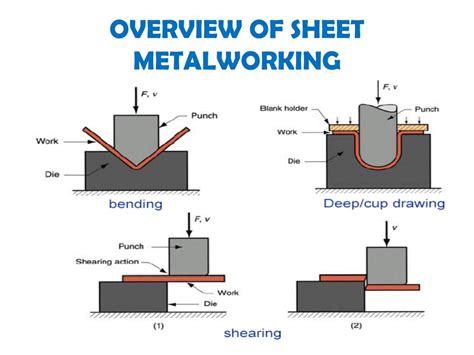

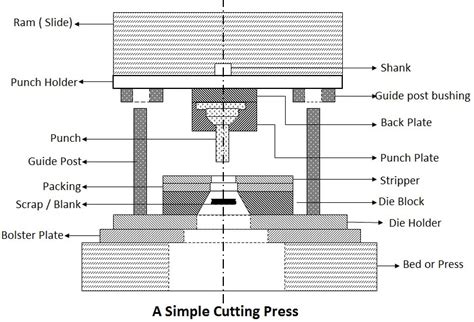

These challenges have caused a need for developing manufacturing processes in general, including obviously those devoted in particular to the development of thin-walled metallic shapes, as is the case with tubular and sheet metal parts and devices.This Special Issue is thus devoted to research in the fields of sheet metal forming and tube .Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required. Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. . Coming to the sheet metal forming processes itself, drawing and bending are the two most widely used techniques in sheet metal industry. . View PDF View article View in .

sheet metal stamping process pdf

The book gives a synthetic presentation of the research performed in the eld of sheet metal forming simulation during more than 20 years by the members of three international teams: the Research Centre on Sheet Metal Forming—CERTETA (Technical University of Cluj-Napoca, Romania); AutoForm Company from Zürich, Switzerland and VOLVO automotive . New York: Industrial Press, 2004. XIX, 219 p. ISBN10: 0831131829. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design - still the most commonly used methodology for the mass-production manufacture.Sheet Metal Forming: Processes and Applications. Edited by Taylan Altan; Taylan Altan Search for other works by this author on: This Site. Google Scholar. A. Erman Tekkaya . Soumya Subramonian, Blanking, Sheet Metal Forming: Processes and Applications, Edited By Taylan Altan, A. Erman Tekkaya, ASM International, 2012, p 1–17, .Download PDF - Sheet Metal Forming: Processes And Applications [PDF] [31fbjio6cl70]. This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equi.

This chapter presents two case studies; one demonstrating the use of finite-element analysis (FEA) in the design of a progressive die forming operation, the other explaining how software simulations helped engineers reduce thinning and eliminate cracking and deformation observed in clutch hubs formed using a three-step transfer die process.

Key Engineering Materials, 2013. The accuracy of the finite element simulation of sheet metal forming processes is mainly influenced by the shape of the yield surface used in the mechanical model and, in particular, by the number of input values used in . Sheet Metal F orming - Bending, . • It is a highly versat ile metal forming process w hich can produce various . • It is a process in which material is shaped b y the application of .

Sheet Metal Forming. Another important forming process is the Sheet Forming process. The sheet-forming process works due to either the tensile force or the shear force. It can be used in Hydraulic presses to make the product from the sheets however some more steps like squeezing, bending, and so on are also included in this process. Request PDF | Development of Electromagnetic Forming Apparatus and Experimental Application to Sheet Metal Forming Processes | The Electromagnetic forming (EMF) method is one of high-velocity .Semantic Scholar extracted view of "SHEET METAL FORMING: Processes and Applications" by M. O. Görtan et al. The application of aluminum alloys in automotive and aerospace industries has been growing significantly in the last 20 years. Due to their high specific strength, aluminum became a strong replacement for steel particularly at automotive manufacturing. However, to deform a complex panel part from aluminum is quite challenging specifically at cold forming .

Berlin - Heidelberg: Springer-Verlag, 2010. — 318 p. Language: English. The book gives a synthetic presentation of the research performed in the field of sheet metal forming simulation during more than 20 years by the members of three international teams: the Research Centre on Sheet Metal Forming - CERTETA (Technical University of Cluj-Napoca, Romania); .As in many other metal forming applications, process planning and design of dies for sheet forming can benefit from a combined application of knowledge based systems and process modeling. Recently, many companies are applying .

The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal forming processes, and focus on the automation of those processes by means of AI techniques, such as KBS, ANN, GA, CBR, etc. Feature recognition and the .Briefly reviews the basic principles of metal forming but major emphasis is on the latest developments in the design of metal-forming operations and tooling. Discusses the position of metal forming in manufacturing and considers a metal-forming process as a system consisting of several interacting variables. Includes an overall review and classification of all metal-forming .Sheet Metal Forming: Processes and Applications on Amazon.com. *FREE* shipping on qualifying offers. Sheet Metal Forming: Processes and Applications . Sheet Metal Forming: Processes and Applications Hardcover – January 1, 1722 . 5.0 5.0 out of 5 stars 2 ratings. See all formats and editions. PDF | In the present study, the survey of research work on finite element analysis of metal forming processes has been carried out. A classification of. | Find, read and cite all the research .

Applications of Metal Forming Process. Applications of Metal Forming Processes across Industries include the following: Automotive Manufacturing: Metal forming plays a pivotal role in the automotive manufacturing sector. Many automobiles integrate sheet metal components meticulously shaped through diverse metal forming techniques.Electrohydraulic forming • EHF is based on the ultra-high-speed deformation of metal using shockwaves in water. • The electric arc in water between two electrodes vaporizes the surrounding water, • converting electrical energy into an intense shockwave of mechanical energy. • The shockwave simultaneously transforms the metal workpiece into a visco-plastic state Types of Forming Process [Notes & PDF] by Er. Amrit Kumar. February 26, 2022. in Manufacturing Technology. 0. 1.7k. SHARES. 6k. VIEWS. Whatsapp Telegram Facebook Twitter. Table of Contents . Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set .This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining.

%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 . Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. This classification involves bending, blanking, stretch forming and deep drawing. Each process has some parameters that define the quality of the work achieved.

Underground Electrical Box Waterproof IP68 Junction Box,2 Way Plug Line M20 Coaxial Cable Junction Box Connector Wire Range 5 to 15mm Outdoor External Electric Power Cord Boxes

sheet metal forming processes and applications pdf|sheet metal forming process pdf