spaceclaim sheet metal Create a drawing sheet to detail your design. Sheet Metal. In this tutorial, you . Underneath the mount is also one of two options for Di2 junction box location (click to enlarge). Other highlights include lightweight FACT 11r carbon frame and Rider-First Engineering in order to provide consistent performance across the entire size range, which includes six frame sizes from 49cm to 61cm.

0 · how to unfold sheet metal

1 · how to make sheet metal parts

Metal Vertical House Number Sign | Mid Century Modern Address Plaque | Retro Style Address Sign | Handmade Vertical House Numbers

how to unfold sheet metal

ultegra di2 bar end junction box

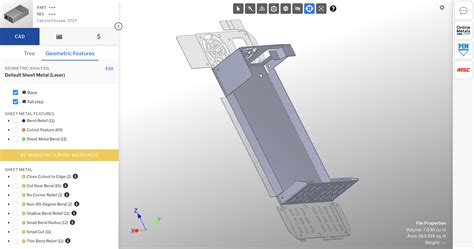

Sometimes it is easier to start with a solid and convert it to create a sheet metal part. This tutorial will guide you through the process and teach you how to use some of SpaceClaim's powerful .Create a drawing sheet to detail your design. Sheet Metal. In this tutorial, you .Sheet metal properties. You can modify the thickness, inner radius, and K-factor .SpaceClaim Assemblies Tutorials; SpaceClaim Communicate Tutorials; .

Sometimes it is easier to start with a solid and convert it to create a sheet metal .

Sheet metal properties. You can modify the thickness, inner radius, and K-factor Parameter of bends in a sheet metal part used to calculate the bend radius. K-factor is a percentage of the .Sometimes it is easier to start with a solid and convert it to create a sheet metal part. This tutorial will guide you through the process and teach you how to use some of SpaceClaim's powerful . http://www.spaceclaim.com/en/Support/Tutorials/Modules/SpaceClaim_Sheet_Metal_Tutorials.aspx?t=105Design enclosures and convert 3D files to unfolded layouts and import and repair unfoldable sheet metal designs. SpaceClaim gives engineers the flexibility to work with any CAD data to create, edit and prepare models for high-precision sheet .

A tutorial on advanced sheet metal tools which strengthen parts and reduce the cost of manufacturing. 5 - Repairing Sheet Metal Parts [Friday, 18 November 2011]

Here are 5 common ways that companies that manufacture sheet metal parts are using SpaceClaim. From the repair of corrupt geometry, optimization and unfoldin. SpaceClaim Assemblies Tutorials; SpaceClaim Communicate Tutorials; SpaceClaim Concept Modeling Tutorials; SpaceClaim Model Prep for CAE & MFG Tutorials; . Product video showcasing the sheet metal features in Spaceclaim. SpaceClaim is the world's fastest and most innovative 3D solid modeler. It gives engineers and industrial .

how to make sheet metal parts

To customize sheet metal options. Select SpaceClaim Options from the File menu to display the SpaceClaim Options window. Click Sheet Metal in the navigation panel on the left. Modify the .Sheet metal tutorial Sometimes it is easier to start with a solid and convert it to create a sheet metal part. This tutorial will guide you through the process and teach you how to use some of SpaceClaim's powerful tools to make your work .Corner reliefs Corner. reliefs are created automatically when you create a sheet metal design or convert a design to sheet metal.. The corner relief type is determined by the Corner Relief option tool in the Modify group on the Sheet Metal tab. The default type is square, but you can change it to another type.SpaceClaim Online Help . Change the Junction type parameter in the Sheet Metal section of the Properties panel to None. Click Pull in the Edit group on the Sheet Metal tab. Select the outside edge of one wall of the junction. Drag the .

Unfolding sheet metal You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design.

The Place the form tool guide is active by default. This tool guide allows you to place a form on any sheet metal face. The Place the form using a grid tool guide allows you to select a face for a sketch plane, and then you can place the form on the plane using the grid. You may want to use this tool guide to help accurately position your form.Converting a design to sheet metal Use the Convert tool in the Import ribbon group on the Sheet Metal tab to convert an existing design to sheet metal within SpaceClaim. You may need to convert if you imported regular geometry or if you moved a part to another component.

Sheet metal properties You can modify the thickness, inner radius, and K-factor of sheet metal components in the Properties panel. Modifying the component's properties affects all the objects in the component. Modified property values appear in bold. You can set the default values for sheet metal components by setting sheet metal options. Delete a modified property value to . Repairing sheet metal parts for unfolding which come in as surfaces or have inconsistent thicknesses throughout the model. SpaceClaim Assemblies Tutorials; SpaceClaim Communicate Tutorials; SpaceClaim Concept Modeling Tutorials; SpaceClaim Model Prep for CAE & MFG Tutorials; SpaceClaim Sheet Metal Tutorials; SpaceClaim Reverse Engineering Tutorials; SpaceClaim 3D Printing Prep Tutorials; SpaceClaim Advanced Repair TutorialsBasic Defaults. Thickness: Type a value for the default wall thickness of sheet metal parts.. Bend Table: Specify an existing Bend Table as the default for new parts.. K-Factor (for R=T): Type a value for the K-factor. The K-factor is a value between .25 and .50 that is used to calculate the bend radius. K-factor is a percentage of the metal thickness and depends on factors such as .

SpaceClaim Online Help You are here: Working with sheet metal > Converting a design to sheet metal. Converting a design to sheet metal Use the Convert tool in the Import ribbon group on the Sheet Metal tab to convert an existing design to sheet metal within SpaceClaim. You may need to convert if you imported regular geometry or if you moved a .The junction type you select is saved as the default for the session, so any junctions created by Pull will be this junction type.. To change a junction on a sheet metal design. Select an edge or face of a junction.. You can Ctrl+click to select multiple junctions.. Select an option from the Junction tool.. You can also select an option from the mini-toolbar or change the Junction type .

http://www.spaceclaim.com/en/Support/Tutorials/Modules/SpaceClaim_Sheet_Metal_Tutorials.aspx?t=105SpaceClaim Online Help You are here: Working with sheet metal > Creating and editing sheet metal > Bending a sheet metal wall. Bending sheet metal walls The Sheet Metal Bend tool works similar to Split Face, and is used to create bends in a sheet metal flat or unfolded part. You can bend along a sketch curve on the sheet metal face, bend .Sheet metal options You can set the wall thickness, bend, and relief defaults for sheet metal components. These defaults can be changed for each component or bend by selecting the component or bend and modifying the property values in .Create a new sheet metal design using the tools on the Sheet Metal tab. See Converting a design to sheet metal if you have already modeled the part. To create a new sheet metal design. Click on the Sheet Metal tab. Select a tool in the Sketch group. Sketch the first wall of your sheet metal part: You can see a preview of the wall's thickness as .

SpaceClaim Assemblies Tutorials; SpaceClaim Communicate Tutorials; SpaceClaim Concept Modeling Tutorials; SpaceClaim Model Prep for CAE & MFG Tutorials; SpaceClaim Sheet Metal Tutorials; SpaceClaim Reverse Engineering Tutorials; SpaceClaim 3D Printing Prep Tutorials; SpaceClaim Advanced Repair Tutorials SpaceClaim's sheet metal capabilities are designed to flatten sheet metal as quickly as possible to get parts ready for production.In this webinar, we'll sho. SpaceClaim Assemblies Tutorials; SpaceClaim Communicate Tutorials; SpaceClaim Concept Modeling Tutorials; SpaceClaim Model Prep for CAE & MFG Tutorials; SpaceClaim Sheet Metal Tutorials; SpaceClaim Reverse Engineering Tutorials; SpaceClaim 3D Printing Prep Tutorials; SpaceClaim Advanced Repair TutorialsUnfolding sheet metal You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design.

SpaceClaim Online Help You are here: Working with sheet metal > Creating and editing sheet metal > Creating a hinge. Hinges Use the Hinge tool in the Sheet Metal tab Create to create hinges at junctions between sheet metal parts. Hinges are defined by the following options: . A sheet metal design or component of a design must be assigned a material in order for the gage drop-down to display. You cannot select a gage for designs or components that are assigned the ‘Unknown Material' option. To assign a material, from the Structure tree select the design at the top level, or select the component for which you want .

Sheet metal lines The Sheet Metal Line tool is primarily used to sketch freeform shapes and to draw lines that will become bends. See Bending a sheet metal wall.. Lines, splines, and arcs are extruded to the thickness of a sheet metal wall when they form a closed profile. You can change the default wall thickness in the sheet metal properties.. . . In addition, you can use the Profile .Pulling sheet metal Use the Pull tool in the Edit ribbon group on the Sheet Metal tab to change sheet metal parts.. Since Sheet Metal thickness faces are thin, and you are likely zoomed out, selecting a non-thickness edge allows both edge and face Pull options. The image below shows that you can choose to pull the edge (dimmed Pull arrow) or pull the face (active Pull arrow). In .SpaceClaim Online Help . If you save an unfolded sheet metal part within a component, opening that component in an assembly displays a checkbox and icon for the unfolded part in the Structure tree . You can toggle the visibility of the unfolded sheet .Sheet metal tutorial Sometimes it is easier to start with a solid and convert it to create a sheet metal part. This tutorial will guide you through the process and teach you how to use some of SpaceClaim's powerful tools to make your work easier, .

Selezionare Opzioni SpaceClaim dal File menu (menu File) per visualizzare la finestra opzioni SpaceClaim. Cliccare Sheet Metal (Lamiera) nel pannello navigazione sulla sinistra. Modificare le opzioni nella pagina. Cliccare OK per salvare tutte le modifiche e chiudere la finestra.

$7,500.00

spaceclaim sheet metal|how to unfold sheet metal