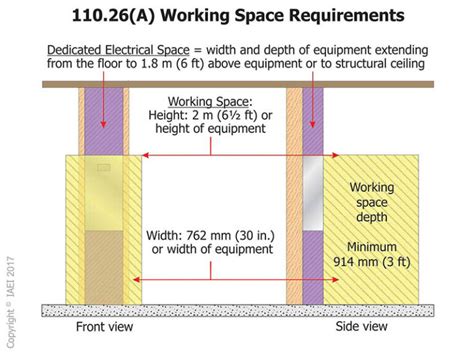

electrical switch box minimum spacing As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, .

Definition of a Septic D-Box: a septic distribution box is a container used to receive septic system effluent from a septic tank and to re-distribute the effluent into a network of attached drain-field or soakaway bed absorption trenches & pipes. The D-box works by gravity, flowing effluent into the drainfield (or leachfield) piping network.

0 · working space voltage requirements

1 · working space for electrical equipment

2 · osha switchboard working space requirements

3 · height of electrical outlet box

4 · floor to bottom light switch box

5 · electrical work space requirements

6 · distance between electrical outlets

7 · clearance for electrical work space

A 4-inch square junction box is exactly what it sounds like: It's 4 inches in size all the way around. These junction box types are primarily used for conductors that are split in two or more directions, per Polycase. Similar to a standard junction box, a 4-inch square junction box is typically best for standard light switches and outlets.

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be .The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be .

Yes, you probably can make a plausible argument that the box is not, "likely to require examination, adjustment, servicing, or maintenance while energized". The short depth .The electrical equipment itself may have a height that is less than 6 1 / 2 feet, but if it is mounted so the top of the equipment is higher than 6 1 / 2 feet, the minimum working space height shall be the equipment height. For example, a .Very specific minimum working space dimensions are required when the equipment requires examination, adjustment, servicing, or maintenance while energized, such as panelboards, .

As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, . Dedicated Electrical Space. Required Space is width and depth of the Panel and extending from the floor to a height of 1.8 m (6 ft) above the equipment or to the structural ceiling, whichever is lowerThe minimum headroom of working space about service equipment, switchboards, panelboards and motor control centers, which require manual operation or where there are energized parts .

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the .Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be less than specified in Table K-2 unless otherwise specified in this subpart.

Requirements for electrical receptacle (outlet or wall plug) spacing, height, and clearances in buildings. Details about spacing, height, and clearance for receptacles are provided in this article. - How to wire and install an electrical outlet

working space voltage requirements

Yes, you probably can make a plausible argument that the box is not, "likely to require examination, adjustment, servicing, or maintenance while energized". The short depth meets code minimums. Plenty of small hvac has a local, .The electrical equipment itself may have a height that is less than 6 1 / 2 feet, but if it is mounted so the top of the equipment is higher than 6 1 / 2 feet, the minimum working space height shall be the equipment height. For example, a panelboard is installed next to a disconnect (safety) switch on a concrete block wall.Very specific minimum working space dimensions are required when the equipment requires examination, adjustment, servicing, or maintenance while energized, such as panelboards, switchboards, and safety switches. As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, panelboards, and motor control centers.

Dedicated Electrical Space. Required Space is width and depth of the Panel and extending from the floor to a height of 1.8 m (6 ft) above the equipment or to the structural ceiling, whichever is lowerThe minimum headroom of working space about service equipment, switchboards, panelboards and motor control centers, which require manual operation or where there are energized parts exposed at any time, shall be as follows:

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be less than specified in Table K-2 unless otherwise specified in this subpart.Requirements for electrical receptacle (outlet or wall plug) spacing, height, and clearances in buildings. Details about spacing, height, and clearance for receptacles are provided in this article. - How to wire and install an electrical outlet Yes, you probably can make a plausible argument that the box is not, "likely to require examination, adjustment, servicing, or maintenance while energized". The short depth meets code minimums. Plenty of small hvac has a local, .

The electrical equipment itself may have a height that is less than 6 1 / 2 feet, but if it is mounted so the top of the equipment is higher than 6 1 / 2 feet, the minimum working space height shall be the equipment height. For example, a panelboard is installed next to a disconnect (safety) switch on a concrete block wall.Very specific minimum working space dimensions are required when the equipment requires examination, adjustment, servicing, or maintenance while energized, such as panelboards, switchboards, and safety switches. As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, panelboards, and motor control centers. Dedicated Electrical Space. Required Space is width and depth of the Panel and extending from the floor to a height of 1.8 m (6 ft) above the equipment or to the structural ceiling, whichever is lower

The minimum headroom of working space about service equipment, switchboards, panelboards and motor control centers, which require manual operation or where there are energized parts exposed at any time, shall be as follows:

working space for electrical equipment

A metal fabricator is a skilled craftsperson who cuts, bends and joins metal pieces to construct various structures and products. From intricate engine parts to sturdy steel bridges, metal fabricators contribute to various industries and projects important to societal development.

electrical switch box minimum spacing|working space for electrical equipment