reworking of sheet metal parts This SOP contains the steps to be followed when the Rework of an in-process or completed Finished Good is required. This SOP covers the following Reworks a. In-Process . TICONN Waterproof Electrical Junction Box IP67 ABS Plastic Enclosure with Hinged Cover with Mounting Plate, Wall Brackets, Cable Glands (Clear, 8.7"x6.7"x4.3") 4.8 out of 5 stars 899

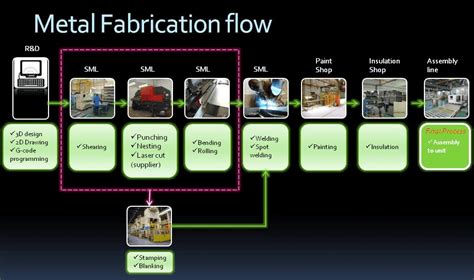

0 · sheet metal manufacturing process

1 · sheet metal fabrication process

2 · scrap and rework process

3 · repairing sheet metal defects

4 · manufacturing rework procedure

5 · how to solve sheet metal problems

6 · how to repair sheet metal

7 · how to fix sheet metal problems

JUNCTION BOX: Install over 2” x 4” junction box with minimum inside dimensions of 3”H x 2”W x 2”D in order to accommodate fixtures. All wires and connections must be contained within junction box. NOTE: Actual depth of box to be determined in accordance with the National Electrical Code (NEC) and local regulations. Indoor or outdoor .

This SOP contains the steps to be followed when the Rework of an in-process or completed Finished Good is required. This SOP covers the following Reworks a. In-Process . If the decision is taken for reworking, then a proper deviation request has to be raised detailing the problem with the date of production, .Blanking: This process involves punching a metal sheet to create a blank. The punched-out component is what you are interested in. Punching: Punching primarily aims to make holes in .

How to remove defects in the sheet metal. Especially for automated processes, you need sheets as they should theoretically be: smooth and flat. In practice, however, there are numerous .

For product design engineers, mastering basic rules of sheet metal design is key to turning part design into high-quality, durable components. This article highlights essential tips for .Challenges in Die Manufacturing. One of the greatest challenges in draw die manufacturing is the large fraction of manual reworking on the die. Weeks or months often pass between milling and initial installation in the . This paper introduces how Dimensional Engineering (DE) process and the simulation-based tolerance analysis used in the sheet metal assembly process. A compliant part tolerance analysis is applied to calculate the flexible .

When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended.Sheet metal parts, with a small ratio of thick-ness to width or length, are widely used in automotive and aerospace industries. Those parts are assembled . • Spending a lot of time reworking or repairing parts that: Fail inspection, but may fit and function prop-erly when assembled. Pass inspection, but do not fit with other parts ICAFT/SFU/AutoMetForm 2018 High-Speed Incremental Forming – New Technologies F r Flexible Production Of Sheet Metal Parts M. Linnemanna*, V. Psyka, E. Djakowb, R. Springerb, W. Hombergb, D. Landgrebea a Fraunhofer Institute for Machine Tools and Forming Technology IWU, Reichenhainer Strasse 88, 09126 Chemnitz, Germany b .Sheet metal parts, with a small ratio of thick-ness to width or length, are widely used in automotive and aerospace industries. Those parts are assembled . • Spending a lot of time reworking or repairing parts that: Fail inspection, but may fit and function prop-erly when assembled. Pass inspection, but do not fit with other parts

If the decision is taken for reworking, then a proper deviation request has to be raised detailing the problem with the date of production, batch code & quantity etc. . For removing small burrs in sheet metal parts. Example: 1. In the case of porosity in welding. 2. In case of hole shift, filling by welding & then redrilling at the OK position.

sheet metal manufacturing process

There are many bending processing methods for sheet metal. Manual bending refers to the processing of bending sheet metal parts using simple tools and manual operations, which mainly include the bending and hemming of thin sheets. Manual bending is one of the important tasks of metal work, and many complex sheet metal parts need to be made by hand.Typical sheet metal parts are studied. 1 INTRODUCTION Process errors, design tolerance specifications, and production cost are closely interrelated. . This reworking cost evaluation procedure .

sheet metal bend deduction calculator

Metals Centre specializes in online sales of cut-to-size metals, including metal orders by phone. We have no minimum quantity orders, but do have a R17.50 minimum charge. Our skilled guillotine and band-saw operators, will cut your material to size, be it sheet metal or plate ranging from, 0.5mm to 12mm thick and round bar from 3mm to 300mm thick. One uses a mix of current jobs and filler parts to fill the sheet and maximize material yield. Another involves only current jobs, which increases remnant management (sometimes called remnant nesting). . EMJD acquires Proto Sheet Metal Products. Industry Events; Pipe and Tube Conference. November 13 - 14, 2024; Omaha, NE; 2025 FMA Annual . Aluminum 5052: This alloy type has impressive malleability with no cracking deficiencies except when reworking. Aluminium 6061: . Since springback is a problem, you need to over-bend sheet metal parts of this material. Sheet Metal Bending Tools And Equipment. Depending on the type of bending style you wish to achieve, you can consider any of .

for Metal Finishing since 1989 -----Reworking a chromated & painted part? Q. I have a rework project coming up where I need to drill some additional holes into an already finished piece of 5052-H32 Aluminum sheet metal. . I have aluminum parts (both A360 diecast & 6061), already chromated and partially white powder coated. .Esteem Metal Fabrication Sdn Bhd was established in 2012 n Johor Bahru, Malaysia. We provide custom made order precision parts, fabrication and sheet metal processing and relevant engineering services. Before incorporated the Company, the founder was worked for several precision sheet metal fabrication companies for over 11 years. Boeing once estimated the cost of reworking or scrapping parts with small distortions at about 0 million or more per year. The high cost of not making an airplane part exactly right the first time can be explained by low production volumes over which the high costs of developing new products and ensuring quality are spread.

sheet metal fabrication process

Stamped and bent parts. made of sheet or strip metal. Take advantage of our experience Our custom-made products: as diverse as your requirements . Repairs/reworking: grinding, milling, honing, lapping, cutting threads, rolling threads, barrel finishing, sandblasting, hardening, heat treating, mounting, pressing; Incremental sheet forming (ISF) is a metal forming process that uses localized deformation from a tool to form a sheet of metal into a 3D shape through a series of small increments. ISF has potential advantages over other sheet .

Ideal for thin sheet metal parts and entire sheets from 0.004" up to to 0.2" (0.1 up to 5 mm) thick are no problem at all for our EcoMaster® precision leveler. . With flat and nearly stress-free parts, reworking and rejects in subsequent .In practice, there are numerous types of deformation. Read more about defects in sheet metal and how to eliminate them. 24h customer hotline . while part straighteners straighten individual parts or blanks. . Welded assemblies can also be assembled much faster, and time-consuming reworking is completely eliminated. More articles. Leveling .

How long is the "UI Modernization" effort going to take. The current rate seems to be reworking about five dialog boxes a year. It feels like aren't many people working on inventor any more. Report. spangler_jack. . I've used SW since november now, primarily for making sheet metal parts that are welded together so the tabs and slot feature .

Discover the EcoMaster® precision levelers from ARKU for thin sheet metal parts & sheets. Best flatness results, high reliability and easy maintenance. 24h customer hotline +49 1805 552758. CAREER . With flat and nearly stress-free parts, reworking and rejects in subsequent processes are reduced. This makes it the number 1 leveling machine .Low-stress sheet metal parts can be welded better. When it comes to welding, the residual stresses in the sheet metal also cause difficulties. The components are more difficult to clamp and setup takes longer. Welding workstations are often a .

Specialist in sheet metal / stainless steel manufacturing and fabrication . VIEW MORE. . Winler (M) Sdn Bhd / Winler Industries Sdn Bhd specialises in laser-cutting products, escalator, lift parts, v-cutting products, signages products and general fabricating products. The company was set up in Masai, Johor, Malaysia. Our key clients are some . Sheet metal tolerance is a specified range that allows for variations in the design dimensions of parts. The manufacturing tolerances range defines the upper and lower limits of the variable design size of the workpiece. Tolerances are critical for ensuring the precision of sheet metal parts, and widely used in sheet metal fabrication.

Causes & Preventation of Defects (Burr) In Sheet Metal Component.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses burrs, a common defect that occurs in sheet metal cutting and forming processes. It identifies the key causes of burrs as issues related to die and punch clearances, raw material grade and thickness, and part .

scrap and rework process

Even with perfect surface quality, reworking on the die cannot be reduced if deflection of the die and press are not accounted for. The Key Role of Digitizing. Digitizing processes are widely used in die manufacturing. The digitization of dies and die parts helps to prevent production outages due to wear or die breakage. . This step is .Select Split (Features toolbar).; In the PropertyManager, under Trim Tools, select the sketch.; Click Cut Part.; Under Resulting Bodies, under , specify the bodies for the split operation.; Optionally, click the callout for each body and save it using the Save As dialog box.

Metals Centre specializes in online sales of cut-to-size metals, including metal orders by phone. We have no minimum quantity orders, but do have a R17.50 minimum charge. Our skilled guillotine and band-saw operators, will cut your material to size, be it sheet metal or plate ranging from, 0.5mm to 12mm thick and round bar from 3mm to 300mm thick.In contrast, microjoints fix the component over the entire sheet thickness, which often requires time-consuming manual reworking and makes part removal more difficult, especially with thin or medium sheet thicknesses. . The Sorting Guide is a camera-based assistance system that assists the worker in removing and sorting sheet metal parts. It .

sheet metal bending defects

sheet metal bending basics

Determine the minimum box volume required for this installation. Calculate the box volume to one decimal place. What is the minimum cubic inch (in.3) volume (or capacity) of each of the following metal boxes in accordance with Article 314?

reworking of sheet metal parts|manufacturing rework procedure