sheet metal chassis fabrication TRIMAP is a full-service Sheet Metal Fabrication and Contract Manufacturing company. We SPecialize in Custom Chassis & Electronic Enclosures. Skip to content. Sheet Metal Fabrication & Contract .

The questions are listed on Leetcode under 'Amazon OA' title, some solutions are gathered from different comments, some of them are my solutions. It is good to have them in one place. .

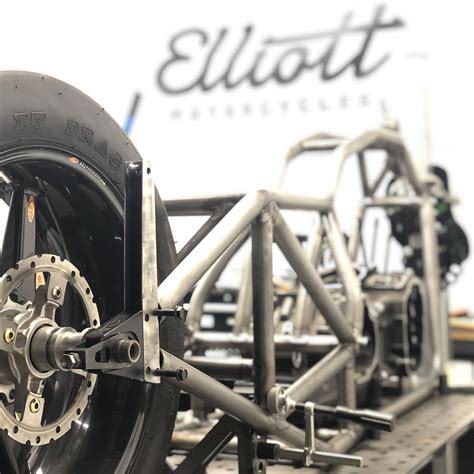

0 · race chassis builders near me

1 · custom chassis fabrication near me

2 · custom chassis builders near me

3 · chassis manufacturers near me

4 · chassis fabrication shops near me

5 · chassis fabrication near me

6 · chassis builder near me

7 · car chassis builders near me

Universal Sheet Metal Ltd. is a roofing and general sheet metal servicing contractor .

Design parts with the sheet metal fabrication process in mind. Reduce cost and get parts on your desk faster! Learn about the following best practices when designing sheet .Sheet Metal Enclosures and Housing Fabrications. Approved Sheet Metal .As a trusted, reliable supplier of US-made custom metal fabricated parts, Fabcon will provide you with innovative and customizable solutions for your project. We’re your one-stop-shop for all your manufacturing requirements, which includes: . Ionthis manufactures custom Sheet Metal Chassis, Housings, Bracket Assemblies, and various Components. Our sheet metal capabilities include types of sheet metal fabrication; .

A sheet metal fabricator is a skilled tradesperson who works with thin sheets of metal to create various structures and components. Their job involves cutting, shaping, bending, and assembling metal sheets into products or parts used in construction, manufacturing, and other industries.Here are some key tasks a sheet metal fabricator typically performs: TRIMAP is a full-service Sheet Metal Fabrication and Contract Manufacturing company. We SPecialize in Custom Chassis & Electronic Enclosures. Skip to content. Sheet Metal Fabrication & Contract .

What is a bracket? In short, the bracket is an intermediate component used to fix one thing (such as a shelf) to another (such as a wall), and the bracket is connected to other parts with actual fasteners such as.Sheet Metal Chassis Supplier. What is the outlook for the metal fabrication industry in 2025?

race chassis builders near me

Boyd uses sheet metal to fabricate thermally conductive enclosures and chassis, heat sinks, and liquid system components. We manufacture single stamped metal thermal conductors, bent metal thermally conductive components, and complex sheet metal assemblies with integrated advanced liquid or air cooling technologies. Our Trumpf press, equipped . Sheet metal fabrication manufacturers cater to a wide range of industries and sectors, each with its specific needs and requirements. Here are some target markets for sheet metal fabrication manufacturers: Automotive Industry: Sheet metal components are .Y2k Precision Sheetmetal Fabrication and machining services. Manufacture cabinets, chassis, enclosures, metal framing, mechanical assemblies, electronic assemblies, and full system integration.

Designing a metal enclosure involves several key steps to ensure it meets functional, structural, and aesthetic requirements. Here’s a detailed guide to help you through the process: Step 1: Define Requirements Dimensions and Shape: Determine the size and shape of.

Electronic sheet metal fabrication, often referred to as electronic sheet metal manufacturing or electronic sheet metal design and fabrication, is a specialized branch of sheet metal fabrication that focuses on producing custom sheet metal components and enclosures for electronic devices and equipment.This process involves the design, cutting, bending, and assembly of sheet . Now there are more and more sheet metal chassis processing products. How to distinguish the advantages and disadvantages of sheet metal processing products is our necessary skill. Because the sheet metal case shell is directly related to the appearance, firmness and process display, safety performance is particularly important. Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal. Functionality: Purpose of the . Sheet metal cutting is a fundamental step in manufacturing, where flat metal sheets are cut into specific shapes and sizes. The cutting method depends on factors like material type, thickness, and the complexity of the design.Here are the .

Chassis. Our staff excels in the design and fabrication of precision sheet metal chassis components. Primarily, the components we manufacture are used to house various electromechanical controls, making all dimensions critical to assure whole pattern alignment between different parts. Designing a sheet metal enclosure requires attention to detail and consideration of various factors to ensure the final product is functional, manufacturable, and cost-effective. Here are some key tips to guide you through the process: 1. Material Selection Choose the.Chassis, housings, panels, frames and brackets. Computer aided manufacturing. Custom product displays. C.N.C. programming and machining. . The people at InMetal take great pride in delivering high quality sheet metal fabrication, on .

Some old group of sheet metal processing engineers like to use AutoCAD as the planning software of sheet metal chassis cabinet sheet metal part product model, and introduce parametric skills. The features have the nature of parameterization, and their features are expressed in the way of parameters. . Custom Metal Fabrication |Sheet Metal .Precision Metal Sheet Fabrication Precision Metal Sheet Fabrication. Services include punching, bending/forming, shearing, graining, welding and outside finishings ; Providing quality products with the closest tolerances at very . Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much smaller than its length. Due to its special geometry and small thickness, it has the advantages of small. Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much .

Ionthis manufactures custom Sheet Metal Chassis, Housings, Bracket Assemblies, and various Components. Our sheet metal capabilities include types of sheet metal fabrication; CNC Turret Punch Press, Traditional Sheet Metal Mold Stamping, Progressive Die Punch Press, Press Brakes, Laser Cutting.A complete list of our Sheet Metal Fabrication Capabilities is listed .

METAL CHASSIS. www.sheetmetalxj.com. SHEET METAL MANUFACTURER IN CHINA . Sheet metal fabrication is a fundamental process for manufacturing metal products. It involves taking metal sheets and forming them into the desired shape and size. Cutting, forming, and finishing are the three methods of metal fabrication.

The sheet metal is placed on the die, and the punch is pressed down on the sheet metal. The huge pressure makes the sheet metal bend. OEM Custom Radiator Support Bracket | Custom Metal Fabrication |Storage Enclosure | ironing. Sheet metal can also be ironed to obtain uniform thickness. For example, many beverage cans are made of aluminum. Surface treatment of hardware: generally, there are painting and electroplating, which are used to prevent rust and form a protective film and anti-static on the surface. IV. special instructions for the internal design of the chassis: the high-quality chassis is.Press brake forming is the most technically challenging operation in sheet metal fabrication. This is one area where talent and technology are absolutely on an equal footing. . CHASSIS InMetal is the place to turn for technically precise, cost-effective production of a wide variety of chassis: from simple to complex, low to high volume, with .

Compared with other thermal cutting methods, laser cutting is characterized by fast cutting speed and high quality. It can be summarized as follows. (1) Good cutting quality Due to the small laser spot, high energy density and fast cutting speed,. Sheet metal connection mainly adopts welding, threaded connection, riveting and bonding. Welding It is a process method for overall or local heating of weldments or plastic deformation of weldments, or plastic deformation and heating are carried out at the same. Sheet metal connection mainly adopts welding, threaded connection, riveting and bonding.

custom chassis fabrication near me

JIATONG XJ was found in March 2011, situated in humen town, with a plant area of 8200 square meters, one of China's professional precison sheet metal manufacturer over 10 years. Offerring you One-stop integrated ODM& OEM manufacturing solutions and services including sheet metal machining, welding, painting, silkscreen, assembly.etc, from primary material cutting to .

The sheet metal fabrication process involves numerous parts – cutting, drilling, punching, welding, forming – all on the strongest metal found on earth. Cutting. . Industries that use custom chassis fabrication are many and varied. These include: Manufacturing. Here you will find architectural and structural metals, boiler, tank and .

industrial bracket metal

custom chassis builders near me

Cape Coral Roofers Phone Number : 866-570-5367 Hours : Mon - Sat 8AM - 6PM EST Email : [email protected]

sheet metal chassis fabrication|custom chassis builders near me