low volume cnc machining ARRK North America, Inc. offers high quality yet rapid low-volume CNC Machining to accomplish your prototyping specifications. Using some of the most progressive and innovative equipment in the industry, this economical option . Bosnia and Herzegovina; Brasil; Bulgaria

0 · low volume metal parts

1 · low volume metal manufacturing

2 · low volume manufacturing

$33.99

Low-volume machining involves manufacturing products in limited or low volumes, between a few units to several thousand. However, the minimum production level can vary .Production CNC Machining | Low Volume to Mass Production. Cost-efficient machined parts at any quantity. Start a Project. We're not only the fastest manufacturing supplier of machined .ARRK North America, Inc. is a leader in the Low-Volume Production industry by providing CNC Machining for your project needs. Utilizing the world’s foremost technology and machinery, this option proves ideal when low-volume .

sheet metal parts laser cutting factories

Low Volume CNC Machining. As a specialized manufacturer of CNC machining, we are equipped with advanced 3-axis, 4-axis, and 5-axis CNC machining centers to provide complex .ARRK North America, Inc. offers high quality yet rapid low-volume CNC Machining to accomplish your prototyping specifications. Using some of the most progressive and innovative equipment in the industry, this economical option . The transition from prototyping to mass production is often incomplete without low-volume machining. Low-volume CNC machining helps to effectively mitigate the risks and additional expenses in the development stages of product manufacturing. However, It is essential to understand low-volume CNC machining basics. This article provides a detailed explanation . The transition from prototyping to mass production is often incomplete without low-volume machining. Low-volume CNC machining helps to effectively mitigate the risks and additional expenses in the development stages of product manufacturing. However, It is essential to understand low-volume CNC machining basics. This article provides a detailed explanation .

Comparing CNC Prototype machining with 3D Printing for Low-Volume Production. Both CNC machining and 3D printing offer impressive methods of making prototypes or product samples in low-volume production. Both manufacturing methods are both good, but there are some benefits that CNC Prototype machining can offer, that 3D printing can’t. .

3ERP is the known as the world's best rapid manufacturing company, offering rapid prototyping & low volume production including CNC machining, vacuum casting, prototype injection molding. Low-volume CNC machining is a means to test a product’s functionality and customer preference before mass production. This service assists manufacturers in increasing the quantity of their product in the market gradually while making necessary modifications. FAQs. Products of CNC machining low volume manufacturing with a high precision of +/-0.01mm, finish up to Ra1.6, suitable for oxidation, sandblasting, painting and powder coating, electroplating, polishing, silkscreen, laser engraving and other surface treatment. 2.High flexibility

Most modern CNC machining services suppliers can handle low- and high-volume CNC machining. However, the CNC software’s level of sophistication, how up-to-date the machines are, and their operational capability determine the lead time of your machining project. Understanding the production CNC machining process and identifying the company .Explore CNC machining, vacuum casting, . Our low-volume manufacturing is adept for making one, ten, or a hundred units of your part. At the same time, our injection molding and die casting operations can mass-produce thousands of your part at cost-effective rates. Choose from over 30 engineering-grade plastic, metals, elastomers, composite .Computer Numerical Control (CNC) machining is when software controls machinery to make precision cuts by removing material from a workpiece to create unique parts. Plastic and metal components can be prototyped or produced with our medium or low-volume CNC machining. By contrast, CNC machining is more appropriate for low-volume production runs with part quantities in the higher double digits or low hundreds, or in projects that have high tolerance requirements. Working with an experienced manufacturing partner

CNC milling is a machining process that utilizes rotating multi-point cutting tools to remove material from a workpiece.It is perfect for manufacturing square or rectangular parts with pockets, holes, threads, and chamfered edges. The low-volume CNC machining method allows for high precision, tight tolerances, and repeatability, making it suitable for low-volume production runs.

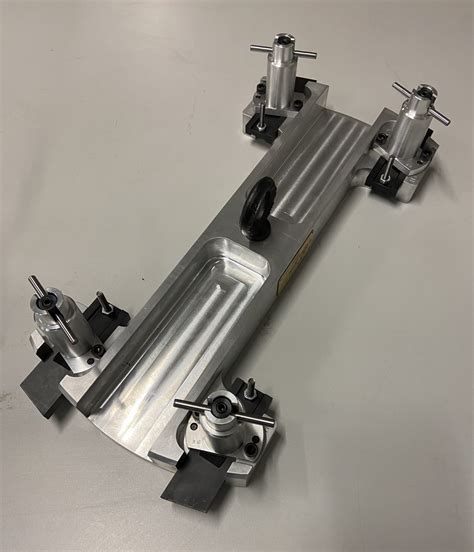

Low-volume CNC machining is often used to create short runs of parts or prototypes. This technology enables manufacturers to produce small quantities of high-quality parts at an affordable price. Low-volume machining requires innovative workholding and a streamlined production process to minimize machine setup time. Elimold excels at low . As shown in the image below, low-volume manufacturing features a certain degree of customization with a small batch of production volume. Several elements play a crucial role in the LVM process: Manufacturing Methods: Depending on the product and material, various manufacturing techniques can be employed, from CNC machining to injection molding . Low-volume CNC machining is a specialized approach to manufacturing, tailored for producing small quantities of parts, typically ranging from 1 piece up to 100 pcs. This method leverages the same advanced CNC .

Low-volume CNC machining refers to the production process where a limited quantity of parts, typically ranging from a few units to a few thousand, is manufactured using Computer Numerical Control (CNC) machines. This approach is particularly advantageous for prototyping, custom parts, and small-batch production runs. .

Low volume CNC machining allows for the production of custom parts without the need for expensive tooling or molds. This is advantageous when producing small batches or one off components tailored to specific requirements. Advantages .CNC turning is a basic process in low-volume CNC machining that involves the workpiece rotating while a stationary cutting tool shapes it. This operation is typically performed on a CNC lathe and is essential for the precise manufacture of cylindrical parts. In low-volume production, turning plays a key role due to its efficiency and accuracy.

When working with complex designs, low-volume rapid CNC machining is a vital tool in modern product manufacturing. The complexity of modern product designs calls for accuracy and precision. Traditional high-volume production is efficient but often requires significant upfront investments in tooling, molds, and setup, which can be expensive for many businesses. For low-volume CNC machining, using the wrong material may increase the overhead cost of processing it. Though almost all materials are compatible with CNC machining, very hard ones need special . High Mix – Low Volume Production (HMLV): What you need to Consider in CNC Machining. Also referred to as make-to-order manufacturing, High Mix – Low Volume (HMLV) manufacturing is the process of making a large variety of products in small batches. A: Low-volume CNC machining refers to the process of making small numbers of high-quality products using computer numerical control (CNC) machines. This method is suitable for production runs that need precision and custom-made components without a .

Low-volume CNC machining is a beacon of design flexibility, outshining traditional methods such as injection molding or die casting. Its adaptability allows for identifying and rectifying manufacturing errors at a fraction of the cost of alternative processes. This adaptability is not just a technical advantage; it empowers companies to . Low-volume plastic molding has a widespread use across various [.] Skip to content. Products Close Products Open Products; Facilities . the mold and its components are made using 3D printing or CNC machining. After manufacturing the mold, parts like the ejector system are installed and the mold is loaded on an injection molding machine. Low volume manufacturing is an innovative bridge between one-off prototyping and full-scale production. This article provides a breakdown of everything you should know. . CNC Machining. CNC-Machining. CNC machining is another perfect process for the low-volume production of parts. The CNC machines are usually fast and easy to install.ARRK. 70+ Years of Expertise in Rapid Prototyping, Low Volume Production, Urethane Casting, 3D Printing, CNC Machining, Tooling and Injection Molding. (858) 434-1822. Global FR. DE. IT. JP. MY. SG. ES. TH. UK. US. . CNC Machining. Machining low-volume CNC precision parts quickly to meet your project requirements.

sheet metal parts pricelist

CNC Machining Low Volume Manufacturing Production Machining Injection Molding Sheet Metal Fabrication. Contact Us. Address: 201-203, Building D, Dingfeng High tech Park, Shapuwei, Songgang, Bao'an District, Shenzhen. Tel:0755-27085144 E-mail: [email protected]

low volume metal parts

sheet metal parts working quotes

low volume metal manufacturing

low volume manufacturing

You can re-do the wiring on your boat trailer with a junction box, but a junction box cannot be submerged as they aren't waterproof. So if you are able to place the junction box in a location that allows it not to be submerged, the best .

low volume cnc machining|low volume metal manufacturing