cnc machine in 2 dimensions In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance.

In sheet metal manufacturing, corrosion resistance is paramount. Galvanized sheet metal offers a superior solution, significantly extending the lifespan and performance of manufactured goods. As such, this article explores the world of galvanized sheet metal, covering its definition, differences from non-galvanized alternatives, and the various galvanization types.

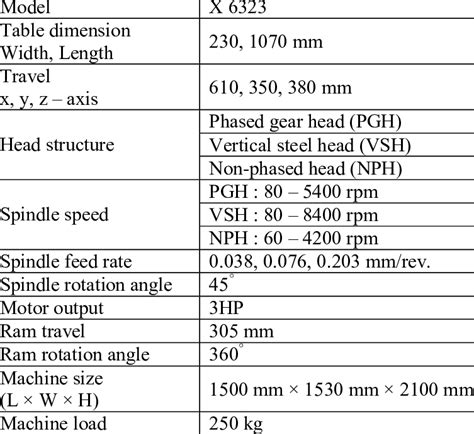

0 · specifications of cnc milling machine

1 · specification of cnc machine

2 · large scale cnc machine

3 · large cnc machine for wood

4 · large cnc cutting machine

5 · cnc machining size consideration

6 · cnc lathe machine specification

7 · best medium size cnc machine

CEF is a Milwaukee metal cutter that processes raw materials with state-of-the-art CNC plate cutting - laser, oxy-fuel flame, high definition plasma cutting and beveling, production sawing - cold and miter, and shear. We precisely form, bend, and roll metal to exacting specifications.

In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance.In this comprehensive guide, we have explored the key dimensions of CNC .

Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. The VF-2 is our most popular model, and the . In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look . CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different .In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance.

Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. The VF-2 is our most popular model, and the workhorse of any shop. 美元价格不包括关税、报关费用、保险费、增值税及运费。 In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look for as a buyer, including how much these CNC machines cost. [lwptoc numeration=”none” skipHeadingLevel=”h3,h4″] What does CNC mean? CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.

2-axis CNC machines are considered the simplest form of CNC system available. They consist of two axes of movement: the X-axis (vertical) and the Y-axis (horizontal). These machines are primarily used for performing straightforward tasks such as creating straight-line cuts or drilling holes in boards. 2-axis CNC machines are the most fundamental CNC systems available. They have two movement axes: the X-axis (vertical axis) and the Y-axis (horizontal axis). These machines often make basic straight-line cuts or drill holes in boards or process only one workpiece surface without relocating it.In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and . Here are the different types of CNC machines according to the number of Axes traveled by the machine. 2-Axis CNC Machines. The most fundamental CNC systems available are 2-axis CNC machines. Machines in this category move in .

You will find all the technical specifications for the Tormach PCNC 1100 CNC mill here, including dimensions, weight, control, power, spindle and maintenance capacities.Below are the specifications for the Shapeoko 5 Pro. If you have any questions, please contact us. 65mm trim router or spindle, either our Carbide Compact Router or VFD Spindle. Windows or Mac computer. (See specifications for computer requirements) Shop vacuum. (Optional but HIGHLY recommended)

In this section, we will provide an overview of CNC machine specifications, explaining their significance in determining the machine's capabilities. We will discuss the primary specifications to consider and their impact on performance.Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. The VF-2 is our most popular model, and the workhorse of any shop. 美元价格不包括关税、报关费用、保险费、增值税及运费。 In this guide, we will look at the various types of CNC machines, including lathe machines, routers, milling machines, grinders, and many more. We’ll uncover how they work, how manufacturers use them, and what to look for as a buyer, including how much these CNC machines cost. [lwptoc numeration=”none” skipHeadingLevel=”h3,h4″] What does CNC mean? CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.

2-axis CNC machines are considered the simplest form of CNC system available. They consist of two axes of movement: the X-axis (vertical) and the Y-axis (horizontal). These machines are primarily used for performing straightforward tasks such as creating straight-line cuts or drilling holes in boards. 2-axis CNC machines are the most fundamental CNC systems available. They have two movement axes: the X-axis (vertical axis) and the Y-axis (horizontal axis). These machines often make basic straight-line cuts or drill holes in boards or process only one workpiece surface without relocating it.In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and .

cooling fabric metallic vest online

Here are the different types of CNC machines according to the number of Axes traveled by the machine. 2-Axis CNC Machines. The most fundamental CNC systems available are 2-axis CNC machines. Machines in this category move in .

specifications of cnc milling machine

You will find all the technical specifications for the Tormach PCNC 1100 CNC mill here, including dimensions, weight, control, power, spindle and maintenance capacities.

cool small cnc machined parts

specification of cnc machine

The calculator below pinpoints exactly which electrode you need for the metal you are welding. You will also get the required polarity, position, and other related information. Additionally, we made the most complete stick welding rod chart PDF on the internet with over 220 electrodes.

cnc machine in 2 dimensions|large cnc machine for wood