five axis cnc machine In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to . Waterproof Junction Box, IP68 Outdoor Junction Box, 2 PCS 3 Way Plug Line External Junction Box, M25 Plastic Electrical Junction Box Suitable for Tunnel Lights, Garden Lights, Landscape Lights

0 · biggest 5 axis cnc machine

1 · best 5 axis cnc machine

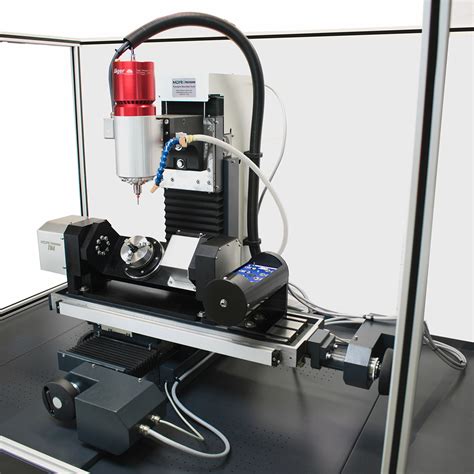

2 · 5 axis desktop cnc machine

3 · 5 axis cnc machine specifications

4 · 5 axis cnc machine price

5 · 5 axis cnc machine manufacturers

6 · 5 axis cnc machine cost

7 · 5 axis cnc explained

Top 10 Best Sheet Metal Shop in Berkeley, CA - September 2024 - Yelp - Crown Heating & Sheet Metal, Jerome & Horner Sheet Metal, Walter Mork, Bay Metals, Master Sheet Metal, El Cerrito Heating & Sheet Metal, ACW Steel, OP Metal Works, Daves Sheet Metal & Copperwork, Advanced Tech Machining

In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to .The Power of 5. 5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position .

FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis . 5-axis CNC machining is a suitable method for hook surface machining, unusual shape machining, hollow machining, oblique hole, etc. While 5-sided machining is similar to .5-axis machining. 5-axis machining enables simultaneous movement along all five axes (X, Y, Z, A, B). This approach allows the tool to access the part from various angles without . A 5 axis CNC machine is meant for industrial-grade machining jobs. They handle complex, intricate jobs. This guide covers their benefits and common uses.

A 5-axis CNC machine moves in five different directions: X, Y, Z simultaneously with A and B. X, Y, and Z are linear axes, while A and B are rotational axes. This type of CNC machine allows an operator to work from all different directions .

The cost of the CNC machine, operator training, and maintenance should also be taken into account. 3-axis machines are the most affordable option, with lower investment and maintenance costs. 4-axis machines have a moderate cost, higher than 3-axis but lower than 5-axis machines. 5-axis machines are the most expensive due to their advanced .

A 5-axis CNC machine is a sophisticated manufacturing tool capable of simultaneously moving a cutting tool or workpiece along five distinct axes of motion. Unlike traditional 3-axis machines, which can only move in three . in this video, we'll look at an example of a 5 axis CNC machining video to understand what 5-axis CNC machining is and how it works. The incredible 5 axis ma.A 5 axis CNC machine is a machining center where multiple tools moving and rotating in different direction for manufacturing complex parts are controlled using a single controller or are performed in a single umbrella. The 5 axis CNC machine, as the.

The Haas UMC Series universal machining centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining. The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T-slots and a precision pilot bore for fixturing versatility. The trunnion provides +120 and -35 degrees of .Equipped with 180mm travel in the X axis, 300mm travel in the Y axis, and 150mm travel in the Z axis, the 5X-100 provides ample space for machining intricate components. Whether you are crafting medical devices, intricate jewellery pieces, precision watch parts, or dental components, the travel range of the 5X-100 is more than sufficient to .

When someone uses the term “5-axis” they are typically referring to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. 3-axis machining centers move a part in two directions (X and Y), and the tool moves up and down (Z). 5-axis CNC machining centers can rotate on two additional rotary axes (A and B), which help the cutting .

In both 5-sided milling and 5-axis simultaneous machining, the premier class of milling, different series from basic models to high-tech machines cover the entire spectrum of high-performance milling technology. Both the accuracy of less than 15 µm in space and the diversity of the component spectrum are impressive. The portfolio offers . In the world of manufacturing, 5-axis machining technology is a new development and ongoing improvement that has changed the way complex parts are made. Haas Automation, a leader in CNC machines, takes the lead in this innovation. In this article we will discuss the development of 5 axis machining technology in Haas CNC machines, their specifications and .

We have 2/3/4/5 Axis machining capabilities. Our equipment is specifically tailored to handle the intricacies of rare metal fabrication. Whether it's titanium, tungsten, tantalum, or any other exotic material, we take pride in having the right machines to complete even the most complex jobs. . Five Axis Industries In Numbers +3,000,000. HOURS . A 5-axis CNC machine is a highly advanced piece of equipment designed for precision machining, comprising several key components: Machine Base: This serves as the foundation of the CNC machine, supporting all other components and absorbing vibrations during operation. Its stability and rigidity are crucial for achieving precise machining results.

A 5-axis CNC bridge saw is a type of machining center that can move its cutting tools along five different axes simultaneously. These axes are typically labeled as X, Y, Z, A, and C. The X, Y, and Z axes control the movement of the cutting tool in three-dimensional space, while the A and C axes allow the cutting tool to tilt and rotate, giving .The cost of purchasing a 5-axis CNC machine and its basic software is high. It is much higher than what is required for a 3-axis machining center. Similarly, the maintenance requirements of the machine are more challenging than those of a conventional machine. This aspect also directly adds to the cost of machining 5-axis parts.

biggest 5 axis cnc machine

Large Moving Table 5-Axis CNC Machine Center, DMS 5 Axis CNC Router. Model:RSKM25-AB. Rhino DAMES 5 Axis CNC Router Woodworking for 3D Mold Sculpture Making. Model:RSKM25-V. Rhino Precision 5-Axis CNC Milling Machine for Advanced 5D Mold Making - RSKM25-T. Model:RSKM25-T.Fully considering the economic change by this health crisis, 5-axis Vertical CNC Machine Tool accounting for 74.75% of the 5-axis CNC Machine Tool global market in 2021, is projected to value US$ 10,893.5 million by 2028, growing at a revised 9.47% .FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis controls with advanced functions for optimal 5-axis tool paths.Desktop 5 axis cnc machine on a tight budget Hey all, Im an aerospace engineering student and have a passion for aerospace and rocketry. I currently own two 3d printers and want to expand my collection to include a 5 axis cnc machine capable of milling stainless steels and mild steels. I have a budget of roughly 0-00 AUD to spend and .

Combine 5-axis machining with other processes: Use additive manufacturing for complex preforms, then finish with 5-axis machining; Combine 3-axis and 5-axis operations on the same part to optimize cost and capability; 2. Invest in Simulation and Optimization Software. Advanced software can help optimize 5-axis machining processes: The end product is the ability to empower the users to generate reliable G-Code which will govern the motions of a CNC machine in order to manufacture any part. I have a very good idea of how a good tool should look and feel, and in Secrets of 5-Axis Machining I can help readers create the perfect toolset for multiaxis machining.” 5-axis CNC machine tool: Tilting worktable type; Tilting spindle type; Tilting worktable/spindle type; Tilted Workbench Type. This refers to the tilted workbench type. The workbench set on the machine bed can rotate around the X-axis, defined as the A-axis, typically operating within a range of +30 to -120 degrees. Jessie shows us a step by step process on how to set up a 5-Axis project using the DVF 5000 from DN Solutions. He then shows us the full process of machining.

A 5-axis CNC machine is a sophisticated tool that allows for the creation of complex parts with high precision and flexibility. Its ability to move in five different directions means it can .5-axis Capability: The U5 provides simultaneous 5-axis machining, allowing for complex and precise operations. This capability enables machinists to create intricate and multi-sided parts with ease. Versatile Machining Options: With a spacious work envelope of 500 x 400 x 250 mm, the U5 can accommodate a wide range of part sizes and shapes. It .KOMO Machine, Inc. is a global leader in providing state of the art, CNC Machining Centers, Parts, Service and Training for any application that would require a 5 Axis CNC machine. We provide a variety of 5-Axis CNC machines: XTREME 5 .

metal corner rabbit litter box

The company's existing products include: five-axis machining center, five-axis turning and milling compound center, horizontal machining center, gantry machining center, vertical machining center, five series and dozens of product models. Learn more NEWS . FLLS professional CNC machine tool manufacturer participated in the MAKTEK EURASIA 2024 . One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine setup. The parts often have complex geometries that don’t easily lend to 3- or 4-axis operations. While many of the parts might be possible without five axes, you’d have to continuously refixture your part. .

metal cutting cnc machine

A water heater junction box is an enclosure that houses essential wiring and connections for a hot water heater system. It is typically situated near the water heater itself and serves as a central location for the water heater’s electrical supply, as well as any other connections or controls the system may need, such as .

five axis cnc machine|5 axis cnc machine cost