best ways to fabricate a sheet metal box _____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i. After devices have been fabricated in the silicon substrate, connections must be made to link the circuits together. This process is called metallization. Metal layers are deposited on the wafer to form conductive pathways.

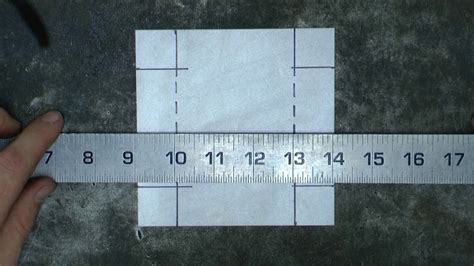

0 · sheet metal box layout

1 · sheet metal box fabrication

2 · sheet metal box drawing

3 · sheet metal box design guide

4 · sheet metal box design

5 · sheet metal blueprints

6 · metal box fabrication

7 · metal box design

The purpose of sheet metal folding is to quickly form large pieces of steel into a bespoke shape using robust machinery. It would be impossible to create the right shape without this process.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as .

Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a .

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal . _____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i. Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make .

Designing a sheet metal box involves several considerations to ensure functionality, durability, and manufacturability. Key factors to consider include: 1. Material Selection.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as safety glasses and gloves.

Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. _____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i. Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

sheet metal box layout

In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization.

sheet metal box fabrication

Designing a sheet metal box involves several considerations to ensure functionality, durability, and manufacturability. Key factors to consider include: 1. Material Selection. Learn how to fabricate sheet metal with CSM’s step-by-step guide. This article covers sheet metal design, cutting, welding, forming, and finishing. In this step-by-step guide, we will delve into the world of custom sheet metal boxes, exploring their significance, applications, and the precise craftsmanship required to create them. A crucial aspect of fabricating custom sheet metal boxes is comprehending the unique requirements of .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.

To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as safety glasses and gloves.

Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on.

_____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization. Designing a sheet metal box involves several considerations to ensure functionality, durability, and manufacturability. Key factors to consider include: 1. Material Selection.

Learn how to fabricate sheet metal with CSM’s step-by-step guide. This article covers sheet metal design, cutting, welding, forming, and finishing.

home intelligent power electricity energy saver box

home depot sheet metal nibbler

sheet metal box drawing

Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from almost any metal.

best ways to fabricate a sheet metal box|metal box design