cnc machine code language CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool . CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

0 · manual cnc programming for beginners

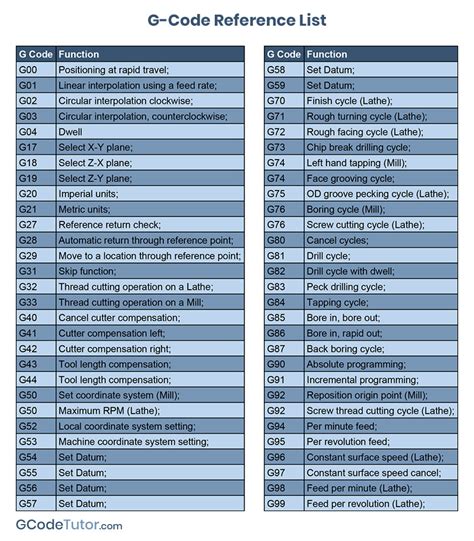

1 · list of cnc g codes

2 · different types of cnc programming

3 · cnc turning g code list

4 · cnc programming languages list

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

This bulletin provides information related to the Smart Junction Box (SJB) software update for certain Sonata, Sonata Hybrid, and Sonata Plug-in Hybrid vehicles. This update .

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool . G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow. Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow. Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw . CNC programming is alphanumeric formatting data (G and M codes) on geometry and technology of parts, which needs to be processed on such a machine, but also another programming, which they usually perform machine manufacturers.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow. Discover G and M codes in CNC programming. Learn how they control machine operations, improve precision, and simplify manufacturing. G and M codes are essential in CNC (Computer Numerical Control) programming, helping . In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool.Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

manual cnc programming for beginners

list of cnc g codes

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

CNC programming is alphanumeric formatting data (G and M codes) on geometry and technology of parts, which needs to be processed on such a machine, but also another programming, which they usually perform machine manufacturers.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow.

Discover G and M codes in CNC programming. Learn how they control machine operations, improve precision, and simplify manufacturing. G and M codes are essential in CNC (Computer Numerical Control) programming, helping . In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool.

different types of cnc programming

metal anti-tarnish jewelry box

A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes.

cnc machine code language|cnc programming languages list