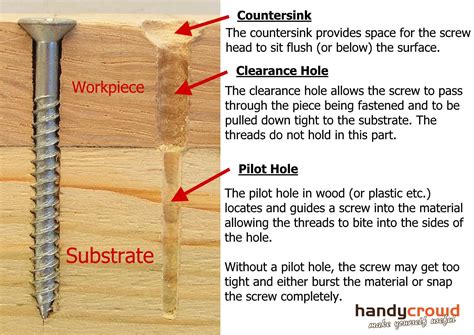

do sheet metal screws need a pilot hole When using a #6 sheet metal screw, it is recommended to pre-drill a pilot hole. The pilot hole should be slightly smaller than the root diameter of the screw. This will ensure that . If your product’s top has an abnormal size, our team can create a custom bottle screw cap that fits perfectly. When choosing a cap, you need one that matches your brand. At SourceCap, we have extensive printing capabilities that allow us to match your style.

0 · what size pilot hole

1 · sheet metal screw drill chart

2 · screw pilot hole chart

3 · pilot screw hole size chart

4 · pilot hole size chart metal

5 · pilot hole for 8 32

6 · metal screw pilot hole chart

7 · 5 16 pilot hole size

A junction box, also known as an electrical box is an enclosed housing space to accommodate electrical connections. But there is a limit on how many wires in a junction box are acceptable. It depends on two key factors. The size of the .

Do I need to drill pilot holes for sheet metal screws? Yes, drilling pilot holes is highly recommended when using sheet metal screws. Since sheet metal is thin and more prone to cracking or splitting, a pilot hole helps prevent these issues and ensures a secure and durable .Pilot Hole Sizes for Steel Sheet Metal . ANSI Hardware Design and Application Guide ISO Metric Hardware Engineering and Design Data Fastener and Screw / Bolt Design, Formula & Calculations. Approximate Pilot Hole Sizes for Type A .

You don’t always have to drill a pilot hole when using sheet metal screws. Most sheet metal screws are self-tapping. They feature a sharp, pointed tip that’s able to create its . For standard sheet metal screws, the recommended pilot hole sizes are as follows: a size-4 screw requires a 3/32-inch pilot hole, a size-6 screw needs a 7/64-inch hole, a . When using a #6 sheet metal screw, it is recommended to pre-drill a pilot hole. The pilot hole should be slightly smaller than the root diameter of the screw. This will ensure that .The sheet metal screws are fundamentally self-tapping. A hole, often referred to as a pilot hole, does not have to be drilled in the workpiece as the self-tapping screwing systems have a cutting edge at the tip which makes a hole as it .

what size pilot hole

However, if using standard sheet metal screws, drill a pilot hole in the sheet metal with a diameter matching the screw’s diameter to facilitate smooth insertion. Position the Screws: Place the sheet metal screws in the . Self-drilling sheet metal screws have a tip that’s more like a drill point to penetrate metal without the need for a pilot hole. It helps preserve the integrity of the material by avoiding denting.All dimensions are in inches except drill sizes. It may be necessary to vary the hole size to suit a particular application. Type C is not recommended for new designs.

electric box 2 29

Do I need to drill pilot holes for sheet metal screws? Yes, drilling pilot holes is highly recommended when using sheet metal screws. Since sheet metal is thin and more prone to cracking or splitting, a pilot hole helps prevent these issues and . 4. Know the Difference Between Pilot Holes and Self-Tapping Screws. Sheet metal screws can be either self-tapping or standard, and it is important to know which one is right for you. Self-tapping screws come with a notched tip that acts as a drill bit to drive the screw and keep the thin metal in your project from denting.Pilot Hole Sizes for Steel Sheet Metal . ANSI Hardware Design and Application Guide ISO Metric Hardware Engineering and Design Data Fastener and Screw / Bolt Design, Formula & Calculations. Approximate Pilot Hole Sizes for Type A Steel Sheet Metal Thread Forming Screws You don’t always have to drill a pilot hole when using sheet metal screws. Most sheet metal screws are self-tapping. They feature a sharp, pointed tip that’s able to create its own threads.

sheet metal screw drill chart

For standard sheet metal screws, the recommended pilot hole sizes are as follows: a size-4 screw requires a 3/32-inch pilot hole, a size-6 screw needs a 7/64-inch hole, a size-8 screw requires a 1/8-inch hole, and so on. When using a #6 sheet metal screw, it is recommended to pre-drill a pilot hole. The pilot hole should be slightly smaller than the root diameter of the screw. This will ensure that the screw can tap its own threads in the metal and create a tight fit.The sheet metal screws are fundamentally self-tapping. A hole, often referred to as a pilot hole, does not have to be drilled in the workpiece as the self-tapping screwing systems have a cutting edge at the tip which makes a hole as it drives in.

However, if using standard sheet metal screws, drill a pilot hole in the sheet metal with a diameter matching the screw’s diameter to facilitate smooth insertion. Position the Screws: Place the sheet metal screws in the predetermined positions on the sheet metal, ensuring that the screw heads are flush with the surface of the sheet metal. Self-drilling sheet metal screws have a tip that’s more like a drill point to penetrate metal without the need for a pilot hole. It helps preserve the integrity of the material by avoiding denting.

All dimensions are in inches except drill sizes. It may be necessary to vary the hole size to suit a particular application. Type C is not recommended for new designs.Do I need to drill pilot holes for sheet metal screws? Yes, drilling pilot holes is highly recommended when using sheet metal screws. Since sheet metal is thin and more prone to cracking or splitting, a pilot hole helps prevent these issues and .

4. Know the Difference Between Pilot Holes and Self-Tapping Screws. Sheet metal screws can be either self-tapping or standard, and it is important to know which one is right for you. Self-tapping screws come with a notched tip that acts as a drill bit to drive the screw and keep the thin metal in your project from denting.

Pilot Hole Sizes for Steel Sheet Metal . ANSI Hardware Design and Application Guide ISO Metric Hardware Engineering and Design Data Fastener and Screw / Bolt Design, Formula & Calculations. Approximate Pilot Hole Sizes for Type A Steel Sheet Metal Thread Forming Screws

You don’t always have to drill a pilot hole when using sheet metal screws. Most sheet metal screws are self-tapping. They feature a sharp, pointed tip that’s able to create its own threads.

For standard sheet metal screws, the recommended pilot hole sizes are as follows: a size-4 screw requires a 3/32-inch pilot hole, a size-6 screw needs a 7/64-inch hole, a size-8 screw requires a 1/8-inch hole, and so on. When using a #6 sheet metal screw, it is recommended to pre-drill a pilot hole. The pilot hole should be slightly smaller than the root diameter of the screw. This will ensure that the screw can tap its own threads in the metal and create a tight fit.The sheet metal screws are fundamentally self-tapping. A hole, often referred to as a pilot hole, does not have to be drilled in the workpiece as the self-tapping screwing systems have a cutting edge at the tip which makes a hole as it drives in. However, if using standard sheet metal screws, drill a pilot hole in the sheet metal with a diameter matching the screw’s diameter to facilitate smooth insertion. Position the Screws: Place the sheet metal screws in the predetermined positions on the sheet metal, ensuring that the screw heads are flush with the surface of the sheet metal.

electric box 2 35

Self-drilling sheet metal screws have a tip that’s more like a drill point to penetrate metal without the need for a pilot hole. It helps preserve the integrity of the material by avoiding denting.

screw pilot hole chart

electric box 2 level 32 solution

electric box 2 walkthrough level 14

By combining the time tested techniques of the the metal working trade with modern methods and machinery we are able to supply construction professionals and the local industries of Wilmington and the surrounding areas with unparalleled service and quality.

do sheet metal screws need a pilot hole|what size pilot hole