modern sheet metal forming processes By reading this article, you will learn: 1. The techniques and processes involved in sheet metal forming, such as bending, stretching, deep drawing, and hydroforming. 2. The types of materials used, including steel, . Wiring diagram of a one way lighting circuit using junction boxes (fig 1). fig 1. The junction box should be wired as shown below. fig 2. Explanation of above picture. (fig 2) The feed cable .

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

On my boats, I typically bypass the factory fuse panel for the electronics and run dedicated 10 awg (or larger) wire from the main breaker to a seperate fuse panel. . Thalweg87 has been a great resource for me on wiring and electronics with my Ranger. Whatever he recommends, I would go with. Viewing 4 posts - 1 through 4 (of 4 total) You must .

sheet metal working process pdf

Sheet metal forming, a versatile manufacturing process that transforms flat metal sheets into complex and intricate shapes, is a crucial aspect of modern engineering. This article, written by experts in the field of sheet . A paradigm shift towards personalised production has brought about the requirement for new, flexible sheet metal forming processes, capable of efficiently forming an .

What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

china cnc laser welding machine

Sheet metal forming is an economical process for large-scale production of parts than metal forging, and die casting processes. It facilitates a wide range of metal options such as; aluminum, tool steel, and galvanized steel. By reading this article, you will learn: 1. The techniques and processes involved in sheet metal forming, such as bending, stretching, deep drawing, and hydroforming. 2. The types of materials used, including steel, . Metal forming processes play a pivotal role in modern manufacturing, shaping raw metallic materials into a diverse array of finished products that range from intricate components to massive structural elements. . Sheet metal forming is a manufacturing process where three dimensional parts are created by flat sheet. There are two process associated with sheet metal forming stamped and forming which are used in aerospace, automobile industries [43]. Stamped product can be curved and bend at one time whereas formed product consist of straight bends.

Let’s take a closer look at what you need to know about modern sheet metal fabrication and how it can help your business: The Power of Precision: CNC and Laser Cutting . CNC machines can automate bending, cutting, and forming processes, based on precise digital designs. It only speeds up production, but also reduces the chance of errors . Friction is the main phenomenon that has a huge influence on the flow behavior of deformed material in sheet metal forming operations. Sheet metal forming methods are one of the most popular .

Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours. . Modern press brakes offer various bending techniques, including air bending, bottoming, and coining, each suited to specific material properties and desired outcomes. The selection of appropriate tooling . PDF | Metal Forming Processes, Bulk forming,Sheet metal forming | Find, read and cite all the research you need on ResearchGate . Nowadays, to improve modern automobiles' fuel economy while .

Sheet metal forming is a cornerstone of modern manufacturing, transforming flat metal sheets into intricate parts and components. It’s an art as much as a science, blending technique, precision, and innovation to meet a broad spectrum of industrial needs. . Curling is a sheet metal forming process that smooths out sharp edges and creates a . Roll Forming Machines: Continuous-feed machines that create long, curved or corrugated sections. Control Systems: Precision at Your Fingertips. Modern sheet metal forming machines incorporate sophisticated control systems that provide precise control over the forming process. These systems include: The subjects of the research articles published in this Special Issue are multidisciplinary, including friction and lubrication in sheet metal forming (SPF), hot strip rolling and tandem strip . This review will help researcher to be familiar about the history, development and state of art of metal forming processes of aluminum sheet alloys. The application of aluminum alloys in automotive and aerospace industries has been growing significantly in the last 20 years. Due to their high specific strength, aluminum became a strong .

Functioning as an introduction to modern mechanics principles and various applications that deal with the science, mathematics and technical aspects of sheet metal forming, Mechanics Modeling of Sheet Metal Forming details theoretically sound formulations based on principles of continuum mechanics for finite or large deformation, which can then be implemented into simulation . Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision-driven process transforms flat metal sheets into intricate components. Over the decades, sheet metal manufacturing has evolved from manual .

A comparison of traditional and modern forming methods is presented here in an attempt to illustrate the evolution of different incremental sheet metal forming techniques.

Precision and efficiency have become the cornerstones of modern metalworking, and metal sheet forming machines stand as prime examples of this technological evolution. These remarkable machines have revolutionized the industry, transforming flat sheets of metal into intricate and functional components. Laser Cutting: A Blade of Precision Laser cutting .

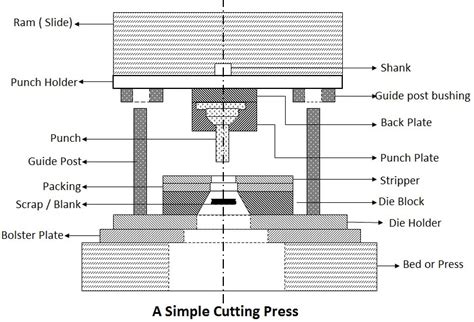

Sheet metal forming processes are typically performed at room temperature on machined tools called Presses using Dies. The parts are referred to as “Stampings”. . They enable the production of complex shapes, precise .After doing research on the modern processes used in sheet-metal forming in the automotive industry for manufacturing the latest technology which is involved in this method are Electro-magnetic forming, Superplastic Forming and Fine blanking process. These processes were more efficient and cost effective while compared to traditional processes .With the continuously growing need for more fuel-efficient and sustainable vehicles, the characterisation and modelling of metal forming processes has been indispensable in the development of new products. In the automotive and .These challenges have caused a need for developing manufacturing processes in general, including obviously those devoted in particular to the development of thin-walled metallic shapes, as is the case with tubular and sheet metal parts and devices.This Special Issue is thus devoted to research in the fields of sheet metal forming and tube .

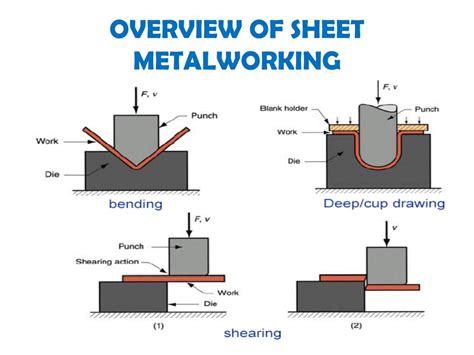

Modern metal sheet forming machines are now equipped with intuitive software interfaces that allow for effortless design, simulation, and optimization of the forming process. Precision at Your Fingertips. The software’s advanced algorithms analyze the design of the desired part and calculate the optimal toolpaths and forming parameters.Written by an engineer with decades of practical manufacturing experience, this new edition has been thoroughly revised and is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. Included are the “hows” and “whys” of .This case study describes modern sheet-metal forming processes used in the automotive industry. This paper presents stages of sheet-metal forming processes such as shearing, blanking, punching, parting, lancing, sheaving, bending, deep drawing, spinning, advantages and disadvantages of this process.

Introduction to sheet metal forming processes. Maziar Ramezani, Zaidi M. Ripin, in Rubber-Pad Forming Processes, 2012. 1.1 Introduction. Sheet metal forming is one of the most important technologies in the industry. In recent years, the demand for sheet metal parts with different shapes and properties has increased dramatically, due to the development of modern industries.Download PDF - Sheet Metal Forming Processes And Die Design [PDF] [ce6pah57mpo0]. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal f.

2. Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually performed as cold working ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision.

Introduction Sheet metal rolling is a fundamental manufacturing process that involves shaping metal sheets into various forms. The Art of Forming: Innovations in Sheet Metal Rolling Technology explores the latest advancements in this field, showcasing the transformative capabilities and enhanced capabilities that are revolutionizing the industry. This .In this report I am going to discuss the modern sheet metal forming processes being used in the current automotive industry. I am going to compare various types of sheet metal forming processes on how they are being used and also how the traditional method have modernised to suit the current demand in the automotive industry.

china cnc laser machine

The Legrand Wiremold 700 series raceway is ideal for surface mounting small amounts of electrical wiring or communication cables. Surface metal raceway allows you to add fixtures and outlets without disturbing the drywall, plaster or .

modern sheet metal forming processes|sheet metal bending process pdf