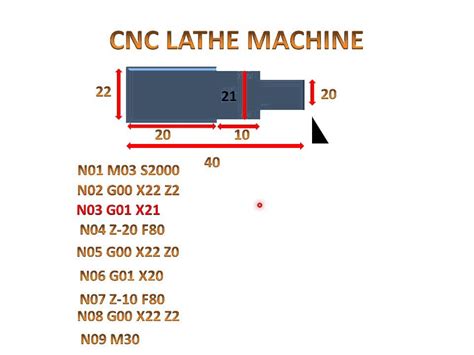

cnc turning part programming examples CNC programming example for CNC machinists who work on CNC Turning/Lathe machines with Siemens Sinumerik 840D/808D CNC controls. Easy to learn . Normally the water level should be completely below the inlet of the drainfield laterals in the dbox. Judging from the image your 2 laterals on the left are completely spent and not taking water, the one on the right is barely taking.

0 · sample cnc program for turning

1 · cnc turning programming with graphics

2 · cnc turning programming pdf

3 · cnc turning program examples pdf

4 · cnc programming examples with drawing

5 · cnc programming examples pdf

6 · cnc lathe programming for beginners

7 · cnc lathe bearing programming examples

Sheet metal manufacturers use different types of welding methods for sheet metal fabrication. The method chosen differs as per the metal being fabricated and the desired end product. Here is a look at the different types of welding methods used in sheet metal fabrication: Gas Metal Arc Welding (GMAW)For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. The Reboot MIG welder supports both flux-cored and solid wires.

By following the step-by-step guide and exploring the provided examples, readers will gain a deeper understanding of CNC turning part programming and be able to produce high-quality turned parts efficiently.

In this comprehensive guide, we have explored CNC turning programming, .

In this blog post, we have explored the essentials of CNC turning programming, .

CNC programming example for CNC machinists who work on CNC Turning/Lathe machines with Siemens Sinumerik 840D/808D CNC controls. Easy to learn .

CNC Programming for Turning. For More Details Click here. Learn CNC Machine operation & Maintenance. Visit here. Facing program; Taper turning; Grooving

In this comprehensive guide, we have explored CNC turning programming, providing step-by-step examples for machining a simple shaft and creating internal threads. By mastering CNC .In this blog post, we have explored the essentials of CNC turning programming, from the basics of G-Code to advanced techniques like contouring and grooving. By providing real-life examples .G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. The Denford Mirac PC is a versatile 2 axis CNC bench turning centre, ideal for all levels of education and technical training. Here is complete list of .A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..

These are the different CNC programming examples we have both turning and milling.To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. .The document provides an overview and instructions for CNC programming for turning operations, including descriptions of programming formats, basic motion commands like linear and circular interpolation, tool radius compensation, .

By following the step-by-step guide and exploring the provided examples, readers will gain a deeper understanding of CNC turning part programming and be able to produce high-quality turned parts efficiently.CNC programming example for CNC machinists who work on CNC Turning/Lathe machines with Siemens Sinumerik 840D/808D CNC controls. Easy to learn and understand cnc program. Siemens Sinumerik CYCLE81 is Drilling. CNC Programming for Turning. For More Details Click here. Learn CNC Machine operation & Maintenance. Visit here. Facing program; Taper turning; GroovingIn this comprehensive guide, we have explored CNC turning programming, providing step-by-step examples for machining a simple shaft and creating internal threads. By mastering CNC turning programming, manufacturers can achieve precision and efficiency in their turning operations.

In this blog post, we have explored the essentials of CNC turning programming, from the basics of G-Code to advanced techniques like contouring and grooving. By providing real-life examples as PDF downloads, we have offered you hands-on experience in creating CNC turning programs.

hamlet sheet metal tongs

G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. The Denford Mirac PC is a versatile 2 axis CNC bench turning centre, ideal for all levels of education and technical training. Here is complete list of Denford Mirac PC.

A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming.. These are the different CNC programming examples we have both turning and milling.

sample cnc program for turning

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.The document provides an overview and instructions for CNC programming for turning operations, including descriptions of programming formats, basic motion commands like linear and circular interpolation, tool radius compensation, subprograms, canned cycles, and a sample program.By following the step-by-step guide and exploring the provided examples, readers will gain a deeper understanding of CNC turning part programming and be able to produce high-quality turned parts efficiently.

CNC programming example for CNC machinists who work on CNC Turning/Lathe machines with Siemens Sinumerik 840D/808D CNC controls. Easy to learn and understand cnc program. Siemens Sinumerik CYCLE81 is Drilling. CNC Programming for Turning. For More Details Click here. Learn CNC Machine operation & Maintenance. Visit here. Facing program; Taper turning; GroovingIn this comprehensive guide, we have explored CNC turning programming, providing step-by-step examples for machining a simple shaft and creating internal threads. By mastering CNC turning programming, manufacturers can achieve precision and efficiency in their turning operations.In this blog post, we have explored the essentials of CNC turning programming, from the basics of G-Code to advanced techniques like contouring and grooving. By providing real-life examples as PDF downloads, we have offered you hands-on experience in creating CNC turning programs.

G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. The Denford Mirac PC is a versatile 2 axis CNC bench turning centre, ideal for all levels of education and technical training. Here is complete list of Denford Mirac PC.A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming.. These are the different CNC programming examples we have both turning and milling.

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

cnc turning programming with graphics

cnc turning programming pdf

Wondering how music boxes work? Music Box Attic has the answers! Check out our overview of how traditional music boxes are made to learn about the process.

cnc turning part programming examples|cnc programming examples pdf