application of cnc machine in manufacturing industry Explore the diverse applications of CNC machines in modern manufacturing. Discover how computer numerical control enhances precision and efficiency across industries. Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

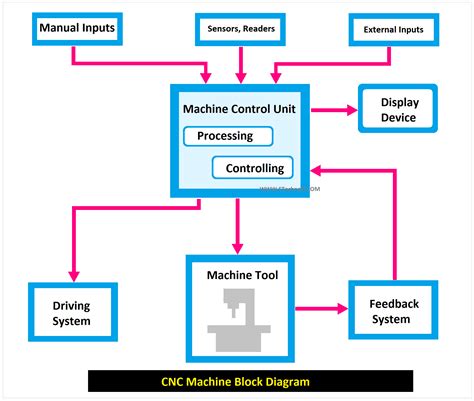

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

$27.20

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Explore the diverse applications of CNC machines in modern manufacturing. Discover how computer numerical control enhances precision and efficiency across industries. CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines, exploring .

stainless sheet metal thickness

Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to .CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used to create prototypes, molds, and final products in various plastic materials with complex geometries.

In the automotive industry, CNC machines are extensively employed to produce engine components, body structures, and interior parts. The high precision and consistency of CNC machining enable automotive manufacturers to improve production efficiency and . Understanding CNC machining is vital in today’s manufacturing landscape, where efficiency, precision, and adaptability are required for lasting success. Industries that demand components meet tight tolerance and function reliably are increasingly choosing CNC machining over other methods. In this post, we discuss CNC machining applications. Below are some industries where CNC machining is applied; 1. Aerospace. In the Aerospace industry, CNC machining has been applied for a very long time. .

In this post, we will explore the application of CNC machines across six different sectors. This includes the aerospace, automotive, renewable energy, marine, medical, and defence industries. At Piran Composites, we specialise in large-scale, five-axis CNC machining and work on world leading projects in a variety of industries. CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Explore the diverse applications of CNC machines in modern manufacturing. Discover how computer numerical control enhances precision and efficiency across industries. CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines. Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities?

CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used to create prototypes, molds, and final products in various plastic materials with complex geometries.In the automotive industry, CNC machines are extensively employed to produce engine components, body structures, and interior parts. The high precision and consistency of CNC machining enable automotive manufacturers to improve production efficiency and .

Understanding CNC machining is vital in today’s manufacturing landscape, where efficiency, precision, and adaptability are required for lasting success. Industries that demand components meet tight tolerance and function reliably are increasingly choosing CNC machining over other methods.

In this post, we discuss CNC machining applications. Below are some industries where CNC machining is applied; 1. Aerospace. In the Aerospace industry, CNC machining has been applied for a very long time. CNC machining technology is used in the manufacture of metal aircraft components. In this post, we will explore the application of CNC machines across six different sectors. This includes the aerospace, automotive, renewable energy, marine, medical, and defence industries. At Piran Composites, we specialise in large-scale, five-axis CNC machining and work on world leading projects in a variety of industries. CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Explore the diverse applications of CNC machines in modern manufacturing. Discover how computer numerical control enhances precision and efficiency across industries. CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines.

Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities?CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used to create prototypes, molds, and final products in various plastic materials with complex geometries.In the automotive industry, CNC machines are extensively employed to produce engine components, body structures, and interior parts. The high precision and consistency of CNC machining enable automotive manufacturers to improve production efficiency and .

Understanding CNC machining is vital in today’s manufacturing landscape, where efficiency, precision, and adaptability are required for lasting success. Industries that demand components meet tight tolerance and function reliably are increasingly choosing CNC machining over other methods.

In this post, we discuss CNC machining applications. Below are some industries where CNC machining is applied; 1. Aerospace. In the Aerospace industry, CNC machining has been applied for a very long time. CNC machining technology is used in the manufacture of metal aircraft components.

schematic diagram of cnc machine

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

application of cnc machine in manufacturing industry|different type of cnc machines