cnc machine products characteristics Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications. Construction began Tuesday on a new 13-foot fence around the White House. The existing fence is six-foot-six inches, and people still manage to find a way to jump the barrier and throw things over it with alarming frequency.

0 · technical descriptions of cnc machine

1 · structure of cnc machine tools

2 · specification of cnc machine

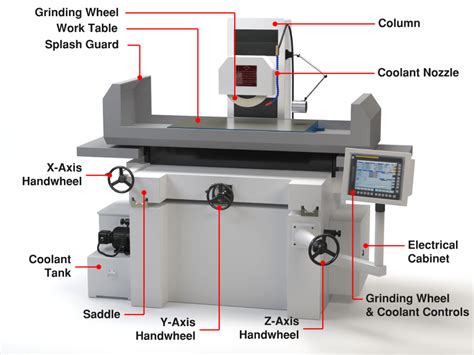

3 · main components of cnc machine

4 · explain working of cnc machine

5 · explain Mcu in cnc

6 · cnc machine types and names

7 · cnc controlled machines

In almost every example shown below, these kitchens feature bright white backsplashes (usually subway tile), white countertops, white appliances, and white seating to create feelings of brightness, airiness, and openness.

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

A computer numerical control (CNC) system has three fundamental components: CNC software which is a program of instruction; a machine control unit; and processing equipment, often known as a machine tool.

CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a .

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.

CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer .

Computer Numerical Control (CNC) machining is a modern, efficient, and automated subtractive manufacturing process that allows manufacturers to make repeatable parts of consistent quality from a wide .Check out the advantages and characteristics of CNC machining, 5-axis machining and more. CNC machining is a subtractive fabrication method to use high speed automated, numerically controlled machines equipped with lots of .CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a .However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you .

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1. A computer numerical control (CNC) system has three fundamental components: CNC software which is a program of instruction; a machine control unit; and processing equipment, often known as a machine tool.

CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it.Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer Numerical Control) is. Computer Numerical Control (CNC) machining is a modern, efficient, and automated subtractive manufacturing process that allows manufacturers to make repeatable parts of consistent quality from a wide range of materials, including plastics, metals, and composites.

Check out the advantages and characteristics of CNC machining, 5-axis machining and more. CNC machining is a subtractive fabrication method to use high speed automated, numerically controlled machines equipped with lots of cutting tools to remove materials from the block for creating designed parts.

where is the distribution box on a septic tank

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.

However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you should know. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

technical descriptions of cnc machine

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1. A computer numerical control (CNC) system has three fundamental components: CNC software which is a program of instruction; a machine control unit; and processing equipment, often known as a machine tool. CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it.

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.CNC machining is a subtractive manufacturing process that creates parts by selectively removing portions of a workpiece using cutting tools or media. To understand CNC machining, it's essential to first grasp what CNC (Computer Numerical Control) is. Computer Numerical Control (CNC) machining is a modern, efficient, and automated subtractive manufacturing process that allows manufacturers to make repeatable parts of consistent quality from a wide range of materials, including plastics, metals, and composites.Check out the advantages and characteristics of CNC machining, 5-axis machining and more. CNC machining is a subtractive fabrication method to use high speed automated, numerically controlled machines equipped with lots of cutting tools to remove materials from the block for creating designed parts.

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.

structure of cnc machine tools

specification of cnc machine

Yes, the field strength is different at those two locations, but what matters is the flux. If you integrate the normal component of the field over the entire closed surface, you'll find that it's .

cnc machine products characteristics|explain working of cnc machine