cnc router build part 7 electronics The Mightymill is the name I gave my professional DIY CNC router build that I'm working on. It features IHSV57 servo motors, BT30 ATC CNC spindle, Durfill polymer concrete filling, and more. I describe more background regarding this . Wiring an L5-30 receptacle: To wire an L5-30 receptacle, follow these steps: Turn off the power to the circuit at the main electrical panel. Remove the cover plate from the receptacle box. Connect the hot wires to the gold screws on the L5-30 receptacle.

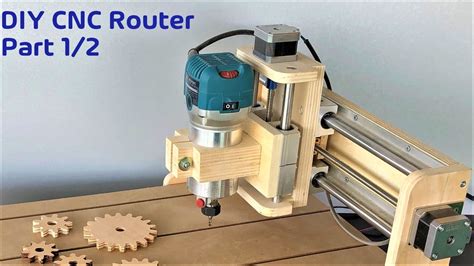

0 · how to build a cnc router

1 · diy cnc router motor

2 · cnc router setup

3 · cnc router plans

4 · cnc router drawing

5 · cnc router design

6 · cnc router cutting instructions

7 · aluminum cnc router design

Wiring diagram of a one way lighting circuit using junction boxes (fig 1). fig 1 The junction box should be wired as shown below. fig 2 Explanation of above picture. (fig 2) The feed cable .

Part 7 of CNC router assembly. Building the electronics panel.I now have a donate button on my HOME PAGE - Click herehttps://www.youtube.com/user/MyRobertad. Homemade CNC Router build. Installation of electronics including stepper motors drivers, breakout board, ESS by Warp 9 and 48v power source . Part 7 of DIY . 38. 1.1K views 1 year ago [Project] CNC router building series/ CNC雕刻機組裝系列. #cnc #cncrouter #diy #3dprinting #marlin #wiring This video is an introduction to CNC router electronics and. In this video I embark upon the journey of building a CNC router machine. My goal is to use the machine to design and build kiteboards, surboards, and other .

The Mightymill is the name I gave my professional DIY CNC router build that I'm working on. It features IHSV57 servo motors, BT30 ATC CNC spindle, Durfill polymer concrete filling, and more. I describe more background regarding this . CNC Router Build Video Workbee Kit 1500mm X 1500mmMusic used This Moment by Jonny EastonLink: https://youtu.be/VObTSz0ufhQ The Great Adventure by Jonny Easto.Ture laser cutters, and true metal cutting CNC routers run in the thousands (plural) of dollars. That's a big investment to try something out. The 5w laser attachments for routers are more of a toy compared to a CO2 or Fiber laser. And, something like a 3018 isn't going to give you an idea of the capacities of a real CNC router, like an Avid . Build Vlog #4 in the series. In this video, I show you all how I built my CNC control box. Then I show how the machine moves and jogs. You don't want to mis.

#cnc #cncrouter #diy #3dprinting #marlin #wiring This video is an introduction to CNC router electronics and their wiring.BTT SKR3 github page:https://github. Hi, in the following two videos I documented the build of my DIY CNC machine. It's a 3-axis router with a wooden frame. Part 1 of the video shows the build of the frame while part 2 shows in detail how all the electronic components are connected. Also in part 2, there's a quick overview of the software and firmware that I use to run the machine . Today we will wire up the PrintNC with an opensource grblhal board and make the first cuts. The PrintNC is a high performance, DIY CNC router. It's based on .Electronics; Media & Info: Build Logs CNC Router Parts Kit Builds . Design and Make Project Series; Media & Info » Build Logs » CNC Router Parts Kit Builds: Displaying 1 to 24 (of 34 results) Result Pages: 1 2 : Scott Thompson Fine Art's PRO4896. Predator Cycling's PRO4848. Rick B.'s PRO4896. Dean and Mary-Ann's CRP4848 Build. Van's PRO4848 .

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm.I finally decided to build a CNC plasma table.I want to do this on a budget, so I will be using as much material that I have on-hand as possible, and hitti.

This clip is about how I mounted some of the electronics in the cnc controller box / cnc electronics enclosure I am putting together for my 6040 CNC router /. Thanks for the responses I've been using the BlackBox with Interface on a mini CNC I built. Love it! My new build, a 1 meter by 1 meter, will have a 1.5K air cooled Spindle. I definitely need to address EMI. When I first purchased the VFD/Spindle I did a bench test to verify operation, the EMI it generated hammered the BlackBox/Interface Didn't damage anything, .#cnc #router #diy Dont forget to SUBSCRIBE to my channel!Thank you!Music:THOMAS VX:https://www.facebook.com/thomasvxhttps://soundcloud.com/thomas-vxhttps://t.I don't have any of the electronics yet as my order is months out, but I wanted to build as much as I can in the meantime. Component Size Estimates: Blackbox Controller ~ 7"x5" VFD ~7"x5" Power Supply ~10"x5" I was thinking about cutting up a PC Case? Any ideas out there?

I'm building a CNC Router. This is the first video in a multi-part build series. The model I chose to build is a modified version of the IndyMill, but with a.I built this cnc using 2 z axis actuators thinking it would minimize deflection and it seems to be very sturdy. I used 2 1500mm c channels for my x axis, 1 1500mm c channel for my y axis, nema 23 stepper motors, dm556 drivers, 2 24v power supplies, smc5-5-n-n controller, 9mm wide belts, and the Hitachi m12vc router. Huanyang vfd manual: http://www.hy-electrical.com/bf/inverter.pdfPlease like and subscribe

Build a CNC Router: Hello, it has been a long time since I read instructables and this is my second one. . To mount the part that hold the router (Makita RT0700C actually), use the 3D printed part (which is in aluminium here). Place it in the threaded rod and screw it with M5 hex head. . Step 7: Electronics. A cnc machine require only a few .Let’s start with the basics for anyone that is new to this. CNC stands for Computer Numerical Control, which extends to many different applications but in most cases is used to describe a machine that is controlled by a computer to remove small amounts of material from a larger piece of material.Most of these machines use a spinning bit with sharp edges to scrape away small . Continuing our PRO CNC Build Series as we review the Plug-and-Play CNC Electronics and Plug-and-Play 2.2kW (3HP) Spindle Option and show how to use these pro.

In this video, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are . Several ways to support this project:- Join the Patreon:https://www.patreon.com/ArcticSeaCamel- Check out the merchandise:https://teespring.com/arctic-seacam.A full size wood router is way more than is needed. I trim router is fine. Openbuilds sells a trim router with an er collet for 0 US. (If your not located in the US, I’m not sure if that’s something that’ll work). On my CNC I use a Cncshield on an arduino uno. A 3-axis DIY CNC router featuring a powerful spindle as well as a 5.5-watt laser engraving module, this versatile CNC router kit is perfect for wood carving and engraving. Hobbyists looking for a versatile machine that does both to a decent standard will enjoy the variety of options Mysweety’s machine offers.

black steel cabinet handles

I want to build an 8x4 CNC Router. This will be my first CNC machine. . machine. Not perfect. Even on the pre-assembled components, check all of your fasteners and loctite them, and check the electronics boxes for anything that looks off before firing up. I had a disconnected ground in one of mine. . Learn before you part with your cash .CNC Machine Electronics for Router, Mill ©2000-2014 Desert Fabworks LLC, . CNC machines require motors to move the various parts of the machine, normally there are 3-4 motors for a machine depending on the size. . On this build we are going to be using Steppers.

how to build a cnc router

diy cnc router motor

cnc router setup

For the receptacle use an old work box and locate it in the same hollow part of the .

cnc router build part 7 electronics|diy cnc router motor