cnc machine types tolerance comparison Today, we have introduced diverse representation methods of linear tolerances, angular tolerances, and numerous form and position tolerances, along with the particular tolerance data of the international general standards. Get the best deals on Steel File Cabinet Antique Furniture when you shop the .

0 · typical tolerances of manufacturing processes

1 · typical cnc machine tolerance

2 · standard tolerance chart for machining

3 · machining tolerances chart

4 · how accurate are cnc machines

5 · cnc tolerance chart

6 · cnc machining tolerance chart

7 · cnc machine tolerance standards

The Best CNC Routers for Woodworking. 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC Machine

While CNC machining servicesare highly accurate when it comes to product dimensions, they are not perfect. The final measurements between any two parts made using the same manufacturing process even on the same CNC machine are always off by a small amount. It is impossible to create identical . See moreEngineering tolerancesare a necessary requirement when defining product measurements. Unless the customer specifies any certain tolerances, the parts will usually be made . See moreNow that we understand why we need tolerance limits and its various types, let’s look at why selecting the right limit is important. The appropriate tolerance limit ensures flawless part . See moreCNC turning and millingare known for the high quality and precision they can provide. At the same time, engineers need to be wary of a few important aspects when choosing the . See more

Today, we have introduced diverse representation methods of linear tolerances, angular tolerances, and numerous form and position tolerances, along with the particular tolerance data of the international general standards. Whether you're producing aerospace parts or consumer electronics, CNC machines offer the efficiency and accuracy needed to meet tight tolerances and fast timelines. For Custom, Low-Volume Work : Traditional machining still has its place, especially in industries that prioritize craftsmanship or require highly customized parts.

CNC machine tools are capable of achieving accuracy up to ±0.0025 mm, but the pursuit of such high-precision machining increases costs. Therefore, it is particularly important to set the tolerance range reasonably, which defines the . Cost: CNC machines typically have higher initial costs but offer long-term savings through automation. Conventional machines are less expensive upfront but may require more manual labor. Maintenance: CNC machines require regular software updates and skilled technicians, while conventional machines need routine mechanical maintenance.A Comparison of Haas and Mazak CNC Machine Quality, Service and Training Options . they are considered top quality CNC’s and new go for as much as 40% more than similar Haas machines. For tight-tolerance work, especially machining tougher materials, many prefer the Mazak. . Get his/her opinion on any specific machine type that you are . What are the 5 common types of CNC machines. The most common types of CNC machines are milling machines, lathes, routers, plasma cutters, and EDMs (Electrical Discharge Machines). Each machine is used for different tasks and materials, making them ideal for .

CNC machines can be costly to acquire, depending on the type and size of the machine. High-precision CNC mills and lathes, for example, often come with a higher price tag. However, CNC machines are known for their durability and longevity, which can provide a good return on investment over time. 3D Printer Equipment Costs

typical tolerances of manufacturing processes

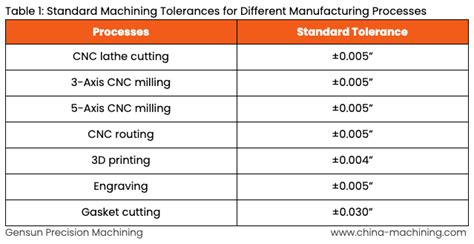

Common CNC Machining Tolerances. CNC machining is a wide field with many different processes under its umbrella. The CNC machining tolerances for each of these processes are different due to variations in the types of cutting tools used. Here are the standard CNC machining tolerances for common processes: Router: ± 0.005″ or 0.13 mm Each of these CNC machine types offers unique capabilities, allowing manufacturers to choose the most suitable option for their specific production needs and material requirements. There are seven main types of CNC machines: milling machines, lathes, routers, plasma cutters, laser cutting machines, drilling machines, and grinding machines. Standard Tolerances. In CNC boring, standard tolerances typically range from +/- 0.005” (0.13 mm) to +/- 0.01” (0.25 mm), sufficient for many general applications and providing a balance between precision and manufacturability. Machine Capabilities. The type of CNC machine significantly impacts tolerance capabilities.Understand the key differences between clearance, transition, and interference fits in engineering. This guide explains how to choose the right fit based on precision, load capacity, and movement needs. Learn how dimensional tolerances play a crucial role in mechanical assemblies and how processes like CNC machining and grinding help achieve the perfect fit for your application.

This step is essential in CNC machining, as it helps achieve accurate and controlled movements along 3D contours and intricate geometries. Interpolation methods, such as linear and circular, guide the CNC machine along precise paths, allowing it to adapt to variations in the part’s shape.

Precision is the cornerstone of CNC machining, and within this realm, CNC machining tolerance takes center stage. Tolerance dictates the allowable variations in dimensions, ensuring that manufactured components meet exact specifications. In this article, we will discuss the role of tolerance in CNC machining, and different types of CNC tolerances. .

CNC Machining Overview. CNC machining, also known as computer numerical control machining, is a manufacturing process that utilizes automated machines to remove material from a workpiece, creating precise and intricate parts.This process offers numerous advantages, including high accuracy, repeatability, and versatility.

typical cnc machine tolerance

standard tolerance chart for machining

machining tolerances chart

Tolerance Levels: If your project requires tight tolerances, CNC grooving is the preferred method, as it provides consistent and highly accurate results. Batch Size: For small quantities or one-off projects, traditional grooving can be cost-effective. CNC machines in general are appreciated due to their high precision and low specified tolerances. However, even within CNC machines, the type of machine used can significantly affect the part tolerances. Therefore, if you have CNC machines in-house, check the tolerance level of the machines beforehand and then design the project accordingly.

Bilateral versus Unilateral Tolerance – Comparison. In my experience as a CNC machinist, it has been noted that the difference between bilateral and unilateral tolerances is well understood in metrology. . When it comes to CNC Machining, the different types of CNC Machines play a great factor in making MPF efficient. Through my analysis of .

Advantages of CNC Machining Compared to 3D Printing. The advantages of CNC machining compared to 3D printing are: CNC machining uses engineering materials and delivers the full properties of the materials, .

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results. 1. CNC Milling Machine. CNC milling machines use rotating cutting tools to remove material from a workpiece. The primary 3-axis CNC machines move along an X-axis (side . The tolerances can vary based on size, configuration, and standards followed. Some machining tolerance types popular in the industry are: 1. General/Standard Tolerance. General tolerances are a common way to define acceptable variations in a part’s dimensions during CNC machining.Buy a Quality CNC Machine. The quality of your CNC machine significantly impacts its precision. High-quality machines offer better performance, reliability, and durability, which is essential for tight tolerances. NextWave CNC sells high-grade CNCs that are the perfect choice for professional woodworkers and DIY enthusiasts.

This difference in final measurements between two parts made from the same CNC machine is accounted for by setting up a standard tolerance limit. The tolerance limit defines the maximum allowable difference between corresponding dimensions of the two parts. For CNC machining, the standard tolerance limit is set around +/-.005” (0.127 mm).Tolerance in machining involves both desing tolerance and the accuracy of the CNC machine l. The Desing tolerance refers to the allowable deviation range in the dimension specified in the CAD model. For example, 20±0.5 mm means if the manufactured dimensions fall under 19.5 to 20.5, it does not affect the intended fit in assembly or performances. In this post, we compare CNC plasma vs waterjet cutting. Both are popular and precise methods of cutting and shaping materials. . In both cases, the max speed varies greatly by the type, size, and quality of machine, along with the materials and design objectives. . For example, a waterjet can produce cuts with tolerances of around +/- .003 .

The CNC laser cutter is indispensable in making complex components with tight tolerances. Each type of CNC machine has an important function in car manufacturing and/or car parts, where much contribution is expected to be produced in high quality and with precision, which can match the tough standards of the industry.

Benefits. Precision: CNC machines have been designed to work with absolute precision, with the level of accuracy ranging in thousands of inches.. Efficiency: Being equipped with both high speed and efficiency CNC milling machines accomplish short lead times with a higher level of productivity.. Versatility: Through CNC milling machines you actually handle a .Comparing Costs Across Different CNC Machine Types 3.1 CNC Milling Machines 3.1.1 Overview. CNC milling machines are a popular choice for creating intricate three-dimensional components. These machines employ rotating cutting tools to remove material from a workpiece. The cost of a CNC milling machine can vary based on several factors.

metal downspout brackets

There are machines that can hold tolerances that cannot be measured with anything but the best computer controlled measuring equipment. A caliper is only a rough measuring tool, many quality CNCs have a repeatability of 0.0002" or well under since they are controlled by a computer not a 200 pound gorilla, so good micrometers or a good CMM are at minimum required to measure .

metal donation box

Discover a collection of quality wooden pipes, pairing unique designs with durable, renewable materials. Shop today for worldwide anonymous shipping.

cnc machine types tolerance comparison|typical tolerances of manufacturing processes