cnc machine numerical control a b c This article will have an in-depth discussion on what is computer numerical control, the basics of CNC programming language, CNC software, the benefits of CNC, various processes, challenges, and other important information.

Let’s look at some of the main ways that you can use an L Bracket: Cabinet and Shelving Units: Many cabinet and shelving units feature an L Bracket for reinforcement. Without one, your unit could bend or warp over time due to weight. That is not a problem with an L Bracket in place because it provides extra support.

0 · who invented cnc machine

1 · what is a cnc mill

2 · numerically controlled machine tool

3 · computerized numerical control cnc

4 · computer numerically controlled machine tools

5 · computer numerical control today

6 · computer numerical control cnc programmer

7 · cnc machine full form

The Septic Tank Distribution Box (DTB) is a critical component within a septic system, responsible for ensuring efficient wastewater distribution and maintaining the system’s functionality. Understanding its purpose, installation requirements, and maintenance costs is .

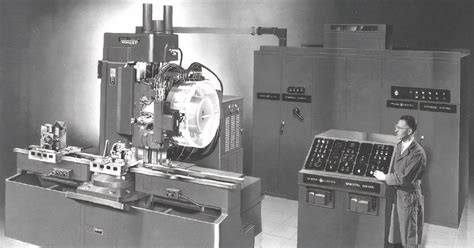

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into a specified shape by following coded programmed instructions and without a m.CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques .

Numerical Control (NC): Definition Use of numbers, letters and other symbols to control the processing equipment - a form of programmable automation (to duplicate/replace human . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various . CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their . This article will have an in-depth discussion on what is computer numerical control, the basics of CNC programming language, CNC software, the benefits of CNC, various processes, challenges, and other important information.

who invented cnc machine

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

sheet metal jobs in indiana

For readers who will eventually be working directly with CNC machine tools, we will show you the basics of each major CNC function. Additionally, we will make suggestions as to how you can learn more about . Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Each machine has its own .In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers .CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques such as milling, water jet cutting, and laser cutting materials.

Numerical Control (NC): Definition Use of numbers, letters and other symbols to control the processing equipment - a form of programmable automation (to duplicate/replace human control of machine tools) Basic Components of NC: 1. Program of instructions Part program in machining 2. Machine control unit Controls the process 3. Processing equipment In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better. CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing. This article will have an in-depth discussion on what is computer numerical control, the basics of CNC programming language, CNC software, the benefits of CNC, various processes, challenges, and other important information.

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . For readers who will eventually be working directly with CNC machine tools, we will show you the basics of each major CNC function. Additionally, we will make suggestions as to how you can learn more about each CNC function as it applies to your particular CNC machine/s. Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce parts with high precision and speed.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Each machine has its own .In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers .

CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques such as milling, water jet cutting, and laser cutting materials.Numerical Control (NC): Definition Use of numbers, letters and other symbols to control the processing equipment - a form of programmable automation (to duplicate/replace human control of machine tools) Basic Components of NC: 1. Program of instructions Part program in machining 2. Machine control unit Controls the process 3. Processing equipment In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better. CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.

This article will have an in-depth discussion on what is computer numerical control, the basics of CNC programming language, CNC software, the benefits of CNC, various processes, challenges, and other important information.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

For readers who will eventually be working directly with CNC machine tools, we will show you the basics of each major CNC function. Additionally, we will make suggestions as to how you can learn more about each CNC function as it applies to your particular CNC machine/s.

For distributions made after December 31, 2023, a distribution to a domestic abuse victim may be made from a 403(b) plan and is not subject to the 10% additional tax on early distributions.

cnc machine numerical control a b c|computer numerical control today