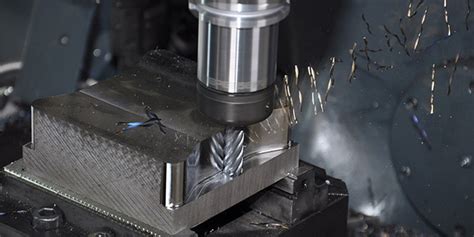

cnc machining stainless steel parts It’s main in CNC machining parts, CNC turning parts, CNC milling parts, auto lathe parts, stamping parts. We're a firm-united team of talented and experienced engineers, machinists and technical consultants, who commit to help solve problems relative to manufacturing precision and complex machined parts, including design, product costing . Subscribe for more Alphablocks Content: https://www.youtube.com/c/officialalphablocks?sub_confirmation=1 As seen on CBeebies! Watch Alphablocks full episodes.

0 · stainless steel prototype

1 · cnc for stainless steel

2 · 316 stainless steel machinability

3 · 316 ss machinability

4 · 304 vs 316 machinability

5 · 304 stainless steel machinability

6 · 304 stainless machinability

7 · 304 ss machinability

Start by scraping off any food residue from the cabinets. Then, wash and scrub the surfaces using synthetic steel wool, soap, and water. Trisodium phosphate (TSP) mixed with water is highly effective for stubborn grease. TSP emulsifies grease, making it much easier to remove than with soap alone.

In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production. Download. Stainless steel parts provide excellent machinability, workability, and .

A.R. Machining manufactures each part to customer-driven specifications. From projects of only one piece to high volume production runs, we produce high-quality parts designed to surpass customer satisfaction. Our 38,000 square-foot facility, forty years of experience and world-class technicians set us apart from our competitors and allows us to produce an extensive list of .It’s main in CNC machining parts, CNC turning parts, CNC milling parts, auto lathe parts, stamping parts. We're a firm-united team of talented and experienced engineers, machinists and technical consultants, who commit to help solve problems relative to manufacturing precision and complex machined parts, including design, product costing .

Stainless Steel Machining. Stainless Steel Machining is a China CNC precision machining manufacturer and Chinese CNC machining company with state-of-the-art CNC manufacturing factory based in China. We provide Stainless Steel Machining, custom 3-5 axis CNC Machining Services, CNC Milling Services, CNC Turning Services, CNC Grinding Services, Wire EDM .Since 2006, China Shenzhen Tuofa CNC Machining Committed to competitive prices and state-of-the-art solutions for CNC machining, sheet metal, 3D printing. Cookies. Tuofa Precision CNC Machining Supplier in China . Tel/WeChat: +8613713980135 Email: info@ . Custom stainless steel machined parts China .

Stainless steel is one of the most valuable and popular CNC materials manufacturers use in making prototypes and custom parts. It is an alloy with iron, chromium, and carbon as its primary alloying elements. However, what is CNC machining stainless steel? It involves using computer numerical control to guide the cutting tools that shape stainless [.]Stainless steel CNC machining is a process of cutting stainless steel materials with computer numerically controlled (CNC) tools. This process involves the use of specialized machinery and software to create custom stainless steel parts for a variety of industries.Years of stainless steel machining experience have provided Miller CNC with the expertise needed for high-performance stainless steel machined parts. Call us at 619-501-9866 or contact us to start your stainless steel project.Advantages of Machining Stainless Steel Parts. Stainless steel is a family of iron-based alloys that contain a minimum of roughly 11 percent chromium, an element that prevents rust and withstands extreme temperatures. This material also has a long cycle life and is 100 percent recyclable, making it environmentally friendly.

As-Machined: As-machined is the most basic and economical CNC finish, often used in applications where the surface won’t be visible, and appearance isn’t a priority. Bead-Blasted: Bead-blasted CNC machining produces a matte finish with texture and evenness.The finish is achieved by blasting stainless steel with an abrasive media such as glass beads, aluminum .

Setting Up A CNC Machine For Stainless Steel. There are many parameters that should be considered when setting up a CNC machine to operate on stainless steel in order to get the best results possible. The initial parameter is selecting the right kind of tooling; typically, carbide tools are preferred due to their hardness and wear resistance .ISO 9001:2015 certified CNC machining services for stainless steels such as 303, 304, 316, 410, 17-4, duplex, and super duplex stainless steel, Nitronic® 60, and Inconel®. . Although machining custom stainless steel parts is highly challenging, customers cannot afford unacceptable delivery delays. Mastering technical challenges while . Custom ordering stainless steel CNC machining parts involves a straightforward process. Firstly, clearly define the specifications, including material grade and dimensions. Following this, identify reputable manufacturers with specialized expertise in stainless steel CNC machining. Reach out to these manufacturers, providing them with detailed .

CNC Aerospace parts: The landing gear, airframes and some jet engine components employ stainless steel components fashioned from CNC machining. Automotive Industry: CNC machined steel parts find use in making different automotive parts such as engine components like connecting rods.

High quality and durable ,tight tolerance stainless steel parts with affordable price ,prompt delivery and superior support from ByTune Electronics here at btcncmachining.com. . we have specialized in Custom 5 Axis CNC Turning Machining Stainless Steel. Read More. Stainless Steel Grinding Machinery Parts. Stainless steel grinding machinery .Tel:+86 15217091354 Fax:076982886112 Mobile:+86 15217091354 Whatsapp:+86-152 1709 1354 E-mail: [email protected] Add:Sifangyuan Industrial Park, Xinshapu, Huaide Community, Humen town, Dongguan City, . Stainless Steel CNC Machining Tips. To ensure the accuracy and efficiency of stainless steel machining, several key points should be considered: 1. Tool Selection: Use tools specifically designed for machining stainless steel, .Online custom stainless steel CNC machining Parts service quotation, 1 day proofing, one-stop service from CNC prototype to mass custom CNC machining stainless steel parts on-demand manufacturing. Cookies +86 15099911516 [email protected] . 14 years one-stop China custom CNC machining parts factory .

Get high-quality Stainless Steel 316L CNC parts fast with Weerg. A corrosion resistant material ideal for applications requiring strength and durability. . CNC machining; Tolerance: ISO 2768-1 fine (f) or medium (m) class. Info; Max size: 300 x 300 x .Other Stainless Steel Materials. SS201: polished without bubbles and pinholes, mostly used in the production of high-quality materials for various watch cases and watchband bottom covers. SS301: Low content of Cr and Ni, the tensile strength and hardness are increased during cold working. non-magnetic, but it is magnetic after cold working. SS304: Good corrosion . Stainless steel CNC machined parts. Stainless steel is an all-around material that has high corrosion resistance, mechanical properties, and good aesthetics. It is used in many industries. In construction, CNC-machined stainless steel parts are applied in doors and windows as well as railings to ensure the safety and solidity of structures.

run the lucky 38 junction box

Because it has outstanding forming & welding qualities, grade 304 is the most adaptable and frequently used stainless steel grade in machining tools. 304L has less carbon than 304 and doesn’t require post-welding, and 304H has more carbon than 304.High quality precision machined 2205/ 2507 Duplex Steel CNC Machining Parts and 304 Stainless Steel Components manufacturer in India . Designation Description Counterpart or Close Alternative; A1: Free-machining grade of ISO 3506 stainless steel. EN 1.4305. SAE 303. A2: Standard grade of ISO 3506 stainless steel. EN 1.4301. SAE 304.Stainless Steel CNC Machining can be summarized as an art of precise and resistant parts manufacturing, which happen to be resistant to corrosion as well. The process is very advanced starting with a CAD/CAM software to design the part geometry and CAM software that line-up the design with G-codes and M-codes for CNC machines.Runsom Precision, a premier manufacturer of stainless steel parts, utilizes advanced 3-, 4-, and 5-axis CNC machining technology to create stainless steel parts with wonderful mechanical properties, high precision, and repeatability. With our extensive experience and top-notch equipment, high-quality stainless steel parts can be produced for complex projects with great .

Stainless steel CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut stainless steel into precise and complex parts or products. During the CNC machining process, a computer program is used to control the movement and operation of the cutting tools, which allows for highly accurate and .Stainless steel CNC machining is a precise manufacturing process that involves the use of computer-controlled machines to remove material from a stainless steel workpiece, resulting in highly accurate and intricate stainless steel components. . The cost of CNC-machined stainless steel parts can vary heavily depending on several factors such .Stainless steel provides high strength and corrosion resistance in a lightweight, aesthetically pleasing package. As a result, the material is perfect for many industrial processes. Improve your application with stainless steel machined parts from Marberry Machine.

stainless steel prototype

A race of aliens arrives on Earth appearing as human but requiring special glasses to protect their eyes; a few suspicious humans discover their true intentions and prepare to resist.

cnc machining stainless steel parts|304 vs 316 machinability