bending process in sheet metal Sheet metal bending is the process of changing a piece of sheet metal’s geometry by applying force to it. The applied force deforms the metal permanently along a straight axis to a given angle or shape, resulting in a new part geometry. You . What are the best CNC machine file formats? When manufacturing parts using Computer-Aided Manufacturing (CAM), two file types are best suited for the job; these are STEP and IGES format. Using a CAM program, the factory can use these file formats to .

0 · sheet metal bending standards

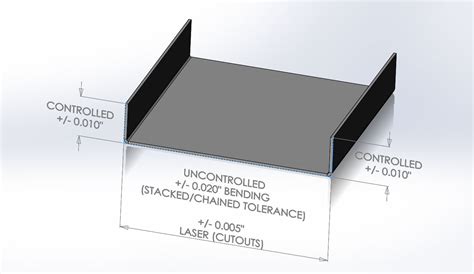

1 · sheet metal bending near me

2 · sheet metal bending guidelines

3 · sheet metal bending dies

4 · sheet metal bending diagram

5 · sheet metal bending design guide

6 · sheet metal bending basics

7 · maximum thickness sheet metal bending

Claim: Five-pointed stars decorating the exteriors of houses mean the inhabitants are "swingers."

In the bending process, sheet metal is deformed along a straight axis to create a desired angle or curvature. Arrange the tooling (die, punches, press brakes) based on your requirements and specified angle. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the . Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Sheet metal bending is the process of changing a piece of sheet metal’s geometry by applying force to it. The applied force deforms the metal permanently along a straight axis to a given angle or shape, resulting in a new part geometry. You .What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation .

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common .Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a . Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final . Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

In the bending process, sheet metal is deformed along a straight axis to create a desired angle or curvature. Arrange the tooling (die, punches, press brakes) based on your requirements and specified angle. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the metal, ensuring accuracy and consistency. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Sheet metal bending is the process of changing a piece of sheet metal’s geometry by applying force to it. The applied force deforms the metal permanently along a straight axis to a given angle or shape, resulting in a new part geometry. You can create several types of shapes using this process. Here are some of them:

sheet metal bending standards

sheet metal bending near me

What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend length depends on punch and die design. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).

Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final . Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. In the bending process, sheet metal is deformed along a straight axis to create a desired angle or curvature. Arrange the tooling (die, punches, press brakes) based on your requirements and specified angle.

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.At its core, sheet metal bending involves applying force to a metal sheet, causing it to bend at an angle and form a desired shape. This process requires specific sheet metal bending machines or press brakes, which exert pressure on the metal, ensuring accuracy and consistency. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Sheet metal bending is the process of changing a piece of sheet metal’s geometry by applying force to it. The applied force deforms the metal permanently along a straight axis to a given angle or shape, resulting in a new part geometry. You can create several types of shapes using this process. Here are some of them:What is Sheet Metal Bending Operation? The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend length depends on punch and die design. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

sheet metal bending guidelines

aws detroit sheet metal welding conference

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

bending process in sheet metal|sheet metal bending near me