how to get electrical cables in box 4 Answers. You can ever so gently stuff them in, but there really isn't all too much that you can do - about the same with any wiring. The 'technique' that I learned is to push one side in first, getting the majority of it in . I assume you’ll be welding thin metal like 1/8” and smaller. I think the titanium mig 140 would be good. If you want to effectively weld 3/16” or thicker you should probably get something that runs on 220/240.

0 · wiring an electrical junction box

1 · running wire into electrical box

2 · residential electrical outlet wiring diagram

3 · how to wire an outlet

4 · electrical junction box instructions

5 · electrical junction box installation instructions

6 · electrical connection box wiring

7 · electrical box installation instructions

Welding thin metal requires precision and the right tools to ensure strong, durable joints without warping or damaging the material. Selecting the appropriate welding rod is crucial, as it influences the weld’s quality, ease of application, and final appearance.

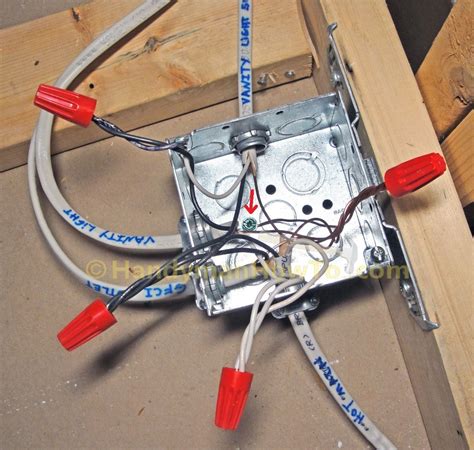

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to complete.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

4 Answers. You can ever so gently stuff them in, but there really isn't all too much that you can do - about the same with any wiring. The 'technique' that I learned is to push one side in first, getting the majority of it in .

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. Yield: Install an electrical junction box. Skill Level: Intermediate. Estimated Cost: to . Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an .When you get the cable nice and neat and flat, and stapled off so it looks well organized and professionally installed, you’re going to inspire a lot more confidence in your work—and possibly in the building inspector, who may show up to take a look at what you’ve done.It is a fast and easy way to pull NM-cables into a box, but not code approved. The photo below shows NM-cables entering the top of a box through NM-connectors (except that one is .

In this video I show you how I fish wires through walls to get them to or from the attic, basement, or different floors, to a new box. Some installers routinely completely knock out the rectangular flap to create an open rectangle for passage of NM cable into a plastic box. I was under the impression that was to be left attached on one side to act as a .

Hello everyone, Just moved in our new (old) house. Checking the loft, I see that the previous owners use loose fill insulation over all the loft. My slight worry is this cover all the wiring and electrical junction boxes. The wiring up here is only for lighting, and all the light fixtures are.If it were me I'd leave the coax not in conduit and put your electrical cable in conduit. Or get direct burial cable and skip the conduit save where it's exposed coming into the shed. . the high voltage where to short to the coax you could get electrical equipment or electrocute someone that touches the cable box. This I understand is a long .So my usual thing is to cut off the connectors. All of 'em, steel or not. It goes quick with a good pair of diagonal cutters. VGA cables, computer power cords, tiny bits of speaker wire, Cat5, whatever. If it's not TV coax, it's fine. And then bag up the wire and drive it over.

Electric Pro AcademyHow to install a new work electrical box and the correct way to run a new wire to the box. Including how to correctly secure the wire wit. Welcome to our Introduction to Electrical Wiring Series: In these process videos, we review the wiring process from installing a junction box to how to wire. My preference is compression butt splices with heat shrink. The actual connector, just like the conductor itself, remains in a dry location, the conductor protected by its insulation and the spice by the heat shrink Some heat shrink is only suitable for moisture protection and others are suitable for submerged locations. Any small opening will allow them access, but it is most often an open knockout hole at the bottom of the box, like the example shown at right, that gives them easy entry. Any wasp species in a panel is bad, but the mud dauber wasp also creates a second problem when they occupy the box over several years and gradually fill it with their mud nests.

waterproof distribution box manufacturer

UF cable must be supported every 30–36 inches (76.2–91.4 cm); just like NM cable. It does not need to be supported in the trench. This cable must be supported when run over concrete. This can be accomplished by securing wood (pressure treated if exposed to outdoors) to concrete and then securing the cable to the wood. The box should be snug. You can always make the hole bigger, never smaller. Feed the cables through the built-in cable clamps and insert the box into the hole. The NEC requires at least 1/4-inch of the exterior plastic sheathing to be inside the box. Tighten the locking swing clamps with a screwdriver or drill to snug the box to the drywall.

In this video I show you how I fish wires through walls to get them to or from the attic, basement, or different floors, to a new box. It may seem like it w.

It depends on two key factors. The size of the box itself, and the size of the cables or conductors. Most non-metallic boxes on the home stores will have a Cubic Inch per junction box printed in them. And there are several box fill guidelines for metal boxes. This article will detail everything you need to know about the wire capacities of a .

water proof steel box

ITEMS I USED ON THIS VIDEO:- Klein Tools Cable Tracer & Probe Tone - https://amzn.to/3jFMiBSALTERNATE CABLE TRACER OPTION:- Electric Circuit Tracer - https:/. Not an electrician, but 2002 National Electrical Code, Section 800-52 (a)(1)(c) Exception No. 1 allows electrical conductors to share an outlet box when the conductors and communications cables are separated by a barrier within the box. Google "dual voltage electrical box" -- they have the dividers at my local big box. Your local code may vary.ITEMS I USED ON THIS VIDEO:- WAGO Wire Connectors (36 Pieces) - https://amzn.to/3l38lmA- WAGO Wire Connectors (75 Pieces) - https://amzn.to/3PhsmDS- WAGO Wir. Having seen the impact that plaster and paint jobs can have on wiring, I'd be more concerned about protecting the wires from the workers! If the breakers are off and stay off, there won't be any live wires for the workers to touch, so they'll be safe.An added safety measure would be to put a wire nut (or Wago™-style lever-locking terminal, screw terminal, or other common .

Wire connectors don't count extra. Each wire that enters the box and makes a joint is counted as one wire. So, if you hae a joint with three wires that counts as 3. Each wire that enters the box and is terminated on a device . ITEMS I USED ON THIS VIDEO:- Flexible Glow Rod Set - https://amzn.to/3ljNj3f- Flexible Auger Drill Bit 3/4” - https://amzn.to/3FOGDDI- Wireless Endoscope Wit. Cut Box Openings . With the cable routes and box locations planned, cut the openings for the electrical boxes in the drywall. Start by marking the desired location for the box on the walls. When installing them in finished walls, electrical boxes should be located between studs. To do this, you must find the location of the wall studs, using a . If you are pulling heavier cables or electrical wires that bind as they are pulled through the bends and fittings of the pipe, you will need to apply a suitable lubricant (often called "soap" by electricians) to the wire as it enters the pipe. . Many "big box" home supply centers sell wire pulling lubricant in the electrical department. In a .

wiring an electrical junction box

Hello my friends. In this video I will show you how to find a missing drywall covered electrical box AKA a missing plug, in a nice and easy way. Disclaimer: .The cable is bent in a z or u shape around posts to hold it in place. The strength of the cable is used to prevent it from being pulled out. Similarly, but less often seen now in the days of cheap molding or diy kits, is this. The cable is screwed into a holder which is prevented from moving in OR out by the case and screw posts.

Here are the steps players can follow to get an Electric Cable in Stray: Step 1 : Head to the Slums. There, you will find Azooz the merchant, who just so happens to have the Electrical Cable if . Nonmetallic, or NM, cable (commonly known by the brand name Romex) must be secured to electrical boxes at the point where the cable enters the box. This code requirement is an important safety feature that protects the wiring . Stick a wire through the ceiling or floor in line with the electrical box. Find a spot where the wall meets the ceiling right above where you want to run your wires. Use a drill with a 1 ⁄ 8 in (0.32 cm) drill bit to make a discreet hole completely through your ceiling or floor. Prep Cable and Secure Cut-In Box. Reach into the hole on the other side of the wall and pull out the NM-B cable. Push the cable through one of the openings in the box, leaving enough to have some slack inside the wall. Cut the cable so you have at least three inches sticking out of the front of the box.

Nailing an electrical box in tight quarters can be frustrating, but Cliff Popejoy, a leadman on a volunteer crew for Habitat for Humanity, has a few ideas to make the task a little easier. . How to Wire a Bathroom: Installing Electrical Boxes View 2 comments. Guide. Wiring. Chapter. Rough-In. View Comments. BGodfrey | May 17, 2018 12:02pm | #1. Plastic or fiberglass electrical boxes aren’t designed to be used with MC cable. Even if you’re able to rig up a connection to a plastic box, you will fail the electrical inspection. Make sure the metal box has knockout holes located where you need them, and don’t rely on the spurs on the bracket to hold the box in place—add a couple of .

running wire into electrical box

warhammer 40k metal boxes

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted surfaces or E6013 for clean surfaces.

how to get electrical cables in box|electrical box installation instructions