aluzinc metal sheet Specified worldwide, Petrochem Aluzinc is the most cost effective, safe, corrosion resistant metal pipework jacketing / cladding for petrochemical insulation protection applications.

An electrical box, also known as a junction box, is an essential component in electrical installations. It serves as a protective enclosure for electrical connections, ensuring .

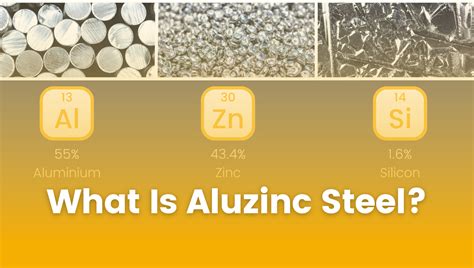

0 · what is aluzinc steel

1 · maisha iron sheets

2 · aluzinc vs galvanized steel

3 · aluzinc sheet specification

4 · aluzinc sheet price

5 · aluzinc roofing sheets

6 · aluzinc roofing sheet prices

7 · aluminium vs aluzinc

The thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. Please note that ASTM states in specification ASTM A480-10a "The use of gage .

Aluzinc® is a flat carbon steel, coated on both sides with an alloy of zinc and aluminium. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process. Aluzinc is, in effect, cold-rolled steel, galvanised with an innovative coating formed from 55% aluminium, 43.3% zinc and 1.6% silicon. The composition of this coating makes the steel up to an astounding six times more resistant to corrosion than standard galvanised metals.

Aluzinc® is a flat carbon steel, coated on both sides with an alloy of zinc and aluminium. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process.The aluminium‐zinc (AZ) coating on steel sheet consists of nominally 55 % aluminium, 43,4% zinc and 1,6% silicon, and it is applied by hot dipping in a molten bath. The excellent corrosion resistance of aluzinc is a result of the properties of the two metallic substances: the barrier effect of the aluminium present on the surface of the .

Aluzinc steel is a kind of highly corrosion-resistant material. It is formed with cold-rolled steel and applied with a coating consisting of 55% aluminum, 43.3% zinc, and 1.6% silicon. It is also known as Galvalume steel.Specified worldwide, Petrochem Aluzinc is the most cost effective, safe, corrosion resistant metal pipework jacketing / cladding for petrochemical insulation protection applications.

Aluzinc is cold rolled galvanized steel with metal coating composed of Aluminium (55%), Zinc (43,4%) and Slicium (1,6%). and other applications where long life is an essential requirement. It is formable, weldable and readily accepts paint finishes. Aluzinc coated steel has superior long term corrosion resistance in most atmospheric conditions.Technical data sheet Aluzinc® Type Continuous hot dip coating Double-sided coating Properties Excellent corrosion resistance Very attractive appearance Excellent thermal and light reflectivity Good abrasion resistance Applications Construction Roofing, cladding, profiling, tiles etc General industry Housings, cabinets and cases for air

Our version is ALZN-ZXD combines the performance of Aluzinc, the strength and rigidity of the ZX profile and the internal protection of the Surlyn moisture barrier. This type of product is also referred to as Aluzinc TM Galvalume TM or Zalutite TM.

Aluzinc® is a flat carbon steel, coated on both sides with an alloy of zinc and aluminium. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process.Aluzinc is an aluminium-zinc coated steel sheet that can be used unpainted up to corrosive class C3. The name AZ150 indicates the coat weight of 150 g/m2 per double side. The surface has been treated with SPT (Surface Protection Treatment) to prevent stains during handling and to . Aluzinc is, in effect, cold-rolled steel, galvanised with an innovative coating formed from 55% aluminium, 43.3% zinc and 1.6% silicon. The composition of this coating makes the steel up to an astounding six times more resistant to corrosion than standard galvanised metals.Aluzinc® is a flat carbon steel, coated on both sides with an alloy of zinc and aluminium. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process.

The aluminium‐zinc (AZ) coating on steel sheet consists of nominally 55 % aluminium, 43,4% zinc and 1,6% silicon, and it is applied by hot dipping in a molten bath. The excellent corrosion resistance of aluzinc is a result of the properties of the two metallic substances: the barrier effect of the aluminium present on the surface of the .

can you install wemo light switch in a metal box

what is aluzinc steel

Aluzinc steel is a kind of highly corrosion-resistant material. It is formed with cold-rolled steel and applied with a coating consisting of 55% aluminum, 43.3% zinc, and 1.6% silicon. It is also known as Galvalume steel.Specified worldwide, Petrochem Aluzinc is the most cost effective, safe, corrosion resistant metal pipework jacketing / cladding for petrochemical insulation protection applications.

Aluzinc is cold rolled galvanized steel with metal coating composed of Aluminium (55%), Zinc (43,4%) and Slicium (1,6%). and other applications where long life is an essential requirement. It is formable, weldable and readily accepts paint finishes. Aluzinc coated steel has superior long term corrosion resistance in most atmospheric conditions.Technical data sheet Aluzinc® Type Continuous hot dip coating Double-sided coating Properties Excellent corrosion resistance Very attractive appearance Excellent thermal and light reflectivity Good abrasion resistance Applications Construction Roofing, cladding, profiling, tiles etc General industry Housings, cabinets and cases for air Our version is ALZN-ZXD combines the performance of Aluzinc, the strength and rigidity of the ZX profile and the internal protection of the Surlyn moisture barrier. This type of product is also referred to as Aluzinc TM Galvalume TM or Zalutite TM.

Aluzinc® is a flat carbon steel, coated on both sides with an alloy of zinc and aluminium. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process.

maisha iron sheets

can you cut eva foam on a cnc machine

A green electrical box, also sometimes known as a junction box or pad mount transformer, is an enclosure specifically designed to house and protect electrical wiring connections in hazardous or extreme environments.

aluzinc metal sheet|aluzinc sheet specification