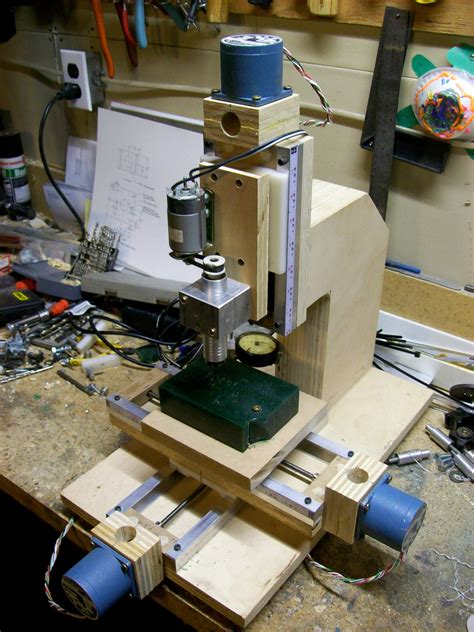

cnc lathe machine diy Homemade DIY CNC lathe in less than 3 minutes. Full video and details on my channel. Stamping dies are typically made with tough materials like steel hard alloys (tool steel) or other similar that can withstand the punching pressure without deformation. We will discuss the technical details of sheet metal stamping dies, and how they bring accuracy and consistency to custom sheet metal components. Let’s start it!

0 · make your own cnc mill

1 · homemade cnc milling machine plans

2 · diy cnc mill kit cost

3 · diy cnc lathe machine

4 · cool cnc lathe projects

5 · cnc lathe conversion kit

6 · build your own cnc mill

7 · build your own cnc lathe

Different types of junction boxes are available depending on the specific needs of the installation. One common type of junction box is the metal or plastic standard rectangular box. This type of junction box is available in different sizes and .

make your own cnc mill

In this comprehensive guide, we will walk you through the process of creating your very own homemade CNC lathe machine, from selecting the right components to assembling and .

When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. . Homemade DIY CNC lathe in less than 3 minutes. Full video and details on my channel. This comprehensive guide provides step-by-step instructions and valuable tips for creating your own CNC lathe machine. Learn the necessary materials, tools, and techniques .

junction box with diode

homemade cnc milling machine plans

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

site: https://www.FishersShopOnline.comPlans: https://www.FishersShopOnline.com/plansInstagram: https://www.Instagram.com/fishersshopStore: https://www.Am.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow . Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY .While seaching for ideas I came across some plan to do a simply cnc conversion to a C1, C2, C3 mini lathe. From the website. The C2 Mini lathe kit was designed specifically for the mini lathe .

This is a short video about how to make a homemade CNC Metal Lathe. It took me about 5-6 months doing it in free time. There was a lot to improve and many things didn't work at the begining.

In this comprehensive guide, we will walk you through the process of creating your very own homemade CNC lathe machine, from selecting the right components to assembling and programming it. So grab your tools and let's get started!When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. Electronics: Motors, controllers, actuators, and a . Homemade DIY CNC lathe in less than 3 minutes. Full video and details on my channel.

This comprehensive guide provides step-by-step instructions and valuable tips for creating your own CNC lathe machine. Learn the necessary materials, tools, and techniques to build a powerful and efficient machine that can revolutionize your machining capabilities.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.site: https://www.FishersShopOnline.comPlans: https://www.FishersShopOnline.com/plansInstagram: https://www.Instagram.com/fishersshopStore: https://www.Am.

junction boxing toronto

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.

While seaching for ideas I came across some plan to do a simply cnc conversion to a C1, C2, C3 mini lathe. From the website. The C2 Mini lathe kit was designed specifically for the mini lathe that many tool resellers sell including Harbor Freight, Grizzly, Homier, and many more.

This is a short video about how to make a homemade CNC Metal Lathe. It took me about 5-6 months doing it in free time. There was a lot to improve and many things didn't work at the begining.In this comprehensive guide, we will walk you through the process of creating your very own homemade CNC lathe machine, from selecting the right components to assembling and programming it. So grab your tools and let's get started!When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. Electronics: Motors, controllers, actuators, and a . Homemade DIY CNC lathe in less than 3 minutes. Full video and details on my channel.

This comprehensive guide provides step-by-step instructions and valuable tips for creating your own CNC lathe machine. Learn the necessary materials, tools, and techniques to build a powerful and efficient machine that can revolutionize your machining capabilities.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

site: https://www.FishersShopOnline.comPlans: https://www.FishersShopOnline.com/plansInstagram: https://www.Instagram.com/fishersshopStore: https://www.Am.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.

diy cnc mill kit cost

Instrumentation and automation architecture consists of field instruments, multi-core cables, junction boxes, marshalling and system cabinets.

cnc lathe machine diy|make your own cnc mill