should you use the ground screw in a junction box Inside each box, you terminate on the box's ground screw, a hole tapped 10-32. If the ground screw already has a wire on it, then either pigtail it so all grounds can share, or drill and tap another 10-32 hole (e.g. with self-tapping screws). Thread pitch must be -32 or finer. Waterproof your outdoor splices with the DryConn medium, aqua/red wire connector. This quality one-step connector is filled with a dielectric silicone sealant that surrounds splices, making it water and corrosion resistant.

0 · metal junction box grounding bolt

1 · metal junction box grounding

2 · metal junction box ground screws

3 · grounding screws on metal box

4 · grounding screws for junction boxes

5 · ground screws in metal conduit

6 · ground screws for metal boxes

7 · do junction boxes ground

A space-efficient, flexible storage solution, this wardrobe offers durable, fully welded steel construction. With one fully adjustable shelf and one fully adjustable shelf with a hanger rod, this cabinet provides flexible storage that .

Inside each box, you terminate on the box's ground screw, a hole tapped 10-32. If the ground screw already has a wire on it, then either pigtail it so all grounds can share, or drill and tap another 10-32 hole (e.g. with self-tapping screws). Thread pitch must be -32 or finer.You don't need a wire to ground the switch, the mounting screws satisfy the . There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding . Several Journeymen have stated that if you run metal conduit, the conduit is considered grounded, thus a ground screw in every j-box is not required (the same answer .

You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means . So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded. Since you're using EMT, the boxes can . After connecting the wires, secure them neatly inside the junction box. Additionally, if the box is made of metal, ensure proper grounding by connecting a ground wire to the grounding screw provided in the box. This . Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be .

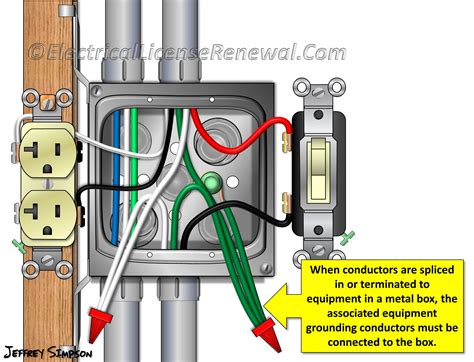

If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. The equipment-grounding wires then connect to the screw, making the metal box . If you’re installing an interior box, use screws or nails to attach the box to a stud, positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of the box should .

metal junction box grounding bolt

In the older versions of the code, you could just tie the ground wires around a screw in the box, such as the 8-32 that is commonly inside boxes to tighten down as a romex clamp. Now you need to use a Green Grounding .In the junction box, see that slightly smaller hole labeled with 'GR'? That's the ground connection point. Proper would be to use a ground screw with a green ground wire from that point. . wire nut (or WAGO) the neutral and line .Not sure if you got an answer to this, but I used one of these bell boxes, they come with a ground screw inside (I'm no expert) but my main line did also still have a ground wire There are two use cases in particular that I'm curious about for this style of grounding. The first use case is receptacles. Say you have an incoming and outgoing cable both with the grounds wrapped and clamped, then the receptacle is attached to the box with a ground screw (e.g. not spliced to the incoming/outgoing grounds).

You can throw a ground wire inside the EMT if you really want to, but I don't bother unless there's a probability of it taking physical damage (takes a lot to damage EMT). Then, same deal; box ground screw to box ground screw. The grounding links the steel boxes. Then the steel boxes carry ground to outlets. On metal boxes, most receps self-groundDeep inside the junction box is a bare copper wire (presumably ground). It was not attached to anything with the previous light fixture. My understanding is that all ground wires need to be connected. I am just not sure exactly where/in what order they should connect, or where they connect to the green ground screw on the mounting piece.

250.4(A)(2),(3), & (4) says that "Normally noncurrent-carrying conductive materials enclosing electrical conductors or equipment" should be grounded and bonded.So while you may not have to connect the equipment grounding conductor to the box, the boxes do have to be grounded and bonded.Ground screws must be -32 thread pitch or finer, and must be threaded into the metal box. 10-32 is the "conventional" size. 10-32 is the "conventional" size. And most metal boxes have a hole tapped for a #10-32 screw for precisely that purpose.You can use a bonding split bolt. Just peel the insulation of the 10/12g at the point where you want to make your joints. You don’t have to cut the copper this way. No issue with connecting it to the box so long as you screw the box ground to the box. Google split bolt CO on Lowe’s website if you aren’t familiar.

If you have this wet niche you will notice the set screw hole for the light fixture is connected the inside bond lug. There are some variations of deck boxes. We use Intermatic's PJB series boxes-all plastic. They have a ground bar inside and an external bond lug. Other companies have a threaded brass base and a plastic top. Junction boxes are used to house electrical connections and are often found in ceilings. The standard screw size for these boxes varies depending on the type of box and its location. For instance, in the US, device boxes typically use 6-32 screws, while junction boxes usually require 8-32 screws. Ground screws, on the other hand, are often 10-32. The bare ECG goes to the green ground screw. For wires that aren’t clearly marked by color, like on a lamp cord, the hot is the smooth wire, and the neutral has ribs, grooves or other markings. 6 / 15. TMB STUDIO (2) Installing Cable Without a Clamp Mistake: Missing cable clamp. . “When using metal junction boxes, it is important to use a .

The old receptacles being replaced are enclosed inside metal junction boxes with copper ground wire attached via screw at the back of each box. Due to the fact that the metal junction boxes are grounded, and since I will be using the original wiring to make connections, will this have any impact, either negative or positive, when I replace the .I opened up an existing junction box to see how it was run, and noticed the ground wires were just tied together and not attached to the actual box. I thought that you could only do that with a plastic box, and if you used metal, one of the grounds had to be attached to the actual box with a ground screw. Is that incorrect, and I can just tie .

metal junction box grounding

It seems that most metal junction boxes have a 10-32 tapped hole to accept a ground screw but almost all of the pre-built pigtails that I've seen that attach to this screw are 12 AWG. Using some sort of ginormous wire nut to connect 2-6 and 1-12 AWG wires doesn't seem like the right move.

In the older versions of the code, you could just tie the ground wires around a screw in the box, such as the 8-32 that is commonly inside boxes to tighten down as a romex clamp. Now you need to use a Green Grounding .

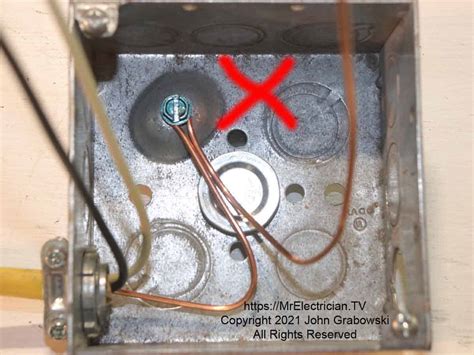

Run deck screws or whatever through the screw holes in the back of the box, which are for that. Do not use the smaller hole which is threaded 10-32 for a ground screw, you need that! Pigtail grounds to that. Better 99 cent boxes put the ground screw on a little bump-out.The problem is, whoever installed the box didn't know the ground screw hole was special, and used it for one of the mounting screws going into the wood. So you'll need to remove each mounting screw, one at a time, and see which one is occupying the threaded hole for the ground screw. Reclaim your ground screw hole, green 10-32 ground screw and .The connecting to a metal box is fine, if the house ground wire is also connected to the box, if you can verify that, then go for it. If you can't, make sure the switch ground is connected to a ground wire within the box. Some boxes are plastic and there are common ground screws since the box itself doesn't conduct electricity. If you do not see a ground screw hole tapped, either the box does not have one (some don't), you're not seeing it because you expect it to be on a dimple and it's flush, or the installer happened to use that hole for a mounting screw/nail. You are welcome to either use a ground clip, or drill and tap a 10-32 hole yourself.

Also can you use a self tapper as ground screw and if not code ref. thanks . Save Share Reply Quote Like. Sort by Oldest first Oldest first Newest first Most reactions. B. Bob Badger. 7511 posts . That section only applys to device terminals not to the ground screw used to connect the EGC to a box. Chris . Reactions: jwjrw.

You can drill and tap more #10-32 ground screw holes into the junction box, if you really want to. That is the conventional size. You can use any thread pitch -32 or finer, and any bolt size #8 or larger. You cannot use sheet metal screws as their pitch is too coarse. Also, you cannot use mounting screws to pinch the ground wire between screw . Now, if the junction boxes are indeed grounded (e.g. via metal conduit as discussed above), here's how you can ground receps. #1: Run a wire to a ground clip or screw (often there's a hole tapped for a #10-32 screw in the back of the steel box). Or #2: Remember how I said you can ground the switch through the mounting screws? If you use the screw that comes with it, how will you secure the cover, plaster ring, fixture, etc? If you use it to connect the EGC, you can't use it for anything else. I just use a green, hex head 10/32. You know, a ground screw. Why give an inspector something to fuss over?

250.148 Continuity and Attachment of Equipment Grounding Conductors to Boxes. Where circuit conductors are spliced within a box, or terminated on equipment within or supported by a box, any equipment grounding conductor(s) associated with those circuit conductors shall be connected within the box or to the box with devices suitable for the use in accordance with 250.148(A) .You will need a 1/2" grounding bushing on the inside of the new junction box, and a small length of #14 awg wire to jump from the grounding bushing to the ground terminal in the new junction box. The original conduit is safe to use as the ground IF AND ONLY IF if it is actually connected solidly back to a good ground point (like your panel) you .

The junction box is for a light socket, but the box is plastic, and the socket doesn't have a ground screw. How would I ground this? Skip to main content. Open menu Open navigation Go to Reddit Home. r/electricians A chip A close button. Get app . Could I use something like an Eaton ground bar in this junction box (Picture attached) if I scrape the paint behind the ground bar, scrape the paint on the opposite side, through nut and bolt it, and run a jumper to the green screw pictured in the box. The largest circuit is 20 amps, so I think I could use a #12 jumper.

metal junction box ground screws

grounding screws on metal box

$0.75

should you use the ground screw in a junction box|grounding screws for junction boxes