can you weld sheet metal with flux core We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding. 4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the manufacturing process.

0 · mig flux core welding basics

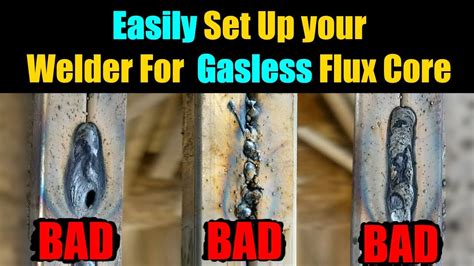

1 · flux core welding troubleshooting

2 · flux core welding techniques

3 · flux core welding setup

4 · flux core welding instructions

5 · flux core welding for dummies

6 · flux core welding for beginners

7 · flux core welding basics

Part (1) of Section 370-16 (a) describes in detail the method of counting wires, as well as clamps, fittings, or devices (i.e., switches, receptacles, combination devices) - by establishing an equivalent conductor-value for each. These .

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . When welding sheet metal using flux core, everything can be a bit messy. Aside from splattering, there’s also the risk of warping, melt-through, and even holes. And they can all double the work you put in.Welding body panels using flux-cored welding is possible, but not recommended. With FCAW the body panel will be more prone to burn through and warping due to the excessive, localized heat. There are some ways to increase your .

The flux core welding method, known as FCAW (Flux-Cored Arc Welding), offers advantages like deep penetration and a forgiving nature when dealing with rusty or dirty metal. Welders must adjust their technique and .

We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding. To weld with flux core, you must set the welding machine to direct current electrode negative (DCEN). This is an important step because most wire feed welders are default set to direct current electrode positive (DCEP) for . In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of .

We're using an .030 Select Arc 700GS, which is a gasless flux core wire designed for running on thin sheet metal and galvanized. We will start with a 18 guage sheet metal lap weld. Welding thin sheet metal with flux core can be a challenging task, but with the right techniques and equipment, it is definitely achievable. Flux core welding offers advantages such as deep penetration and high deposition . Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . When welding sheet metal using flux core, everything can be a bit messy. Aside from splattering, there’s also the risk of warping, melt-through, and even holes. And they can all double the work you put in.

Welding body panels using flux-cored welding is possible, but not recommended. With FCAW the body panel will be more prone to burn through and warping due to the excessive, localized heat. There are some ways to increase your chances and make it happen.

mig flux core welding basics

Flux core welding is an advanced welding technique that uses a special shielding gas to join metallic materials. Unlike gas metal arc welding (GMAW), flux core requires a shielding gas and the ability to arc weld without the need for an electrode. The flux core welding method, known as FCAW (Flux-Cored Arc Welding), offers advantages like deep penetration and a forgiving nature when dealing with rusty or dirty metal. Welders must adjust their technique and equipment settings to manage the heat input and minimize warping or burn-through.

knitted metal fabric

We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding. To weld with flux core, you must set the welding machine to direct current electrode negative (DCEN). This is an important step because most wire feed welders are default set to direct current electrode positive (DCEP) for MIG welding. In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of mastering flux core welding, especially when dealing with delicate 22-gauge sheet metal.

We're using an .030 Select Arc 700GS, which is a gasless flux core wire designed for running on thin sheet metal and galvanized. We will start with a 18 guage sheet metal lap weld. Welding thin sheet metal with flux core can be a challenging task, but with the right techniques and equipment, it is definitely achievable. Flux core welding offers advantages such as deep penetration and high deposition rates, making . Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

flux core welding troubleshooting

When welding sheet metal using flux core, everything can be a bit messy. Aside from splattering, there’s also the risk of warping, melt-through, and even holes. And they can all double the work you put in.Welding body panels using flux-cored welding is possible, but not recommended. With FCAW the body panel will be more prone to burn through and warping due to the excessive, localized heat. There are some ways to increase your chances and make it happen.

Flux core welding is an advanced welding technique that uses a special shielding gas to join metallic materials. Unlike gas metal arc welding (GMAW), flux core requires a shielding gas and the ability to arc weld without the need for an electrode. The flux core welding method, known as FCAW (Flux-Cored Arc Welding), offers advantages like deep penetration and a forgiving nature when dealing with rusty or dirty metal. Welders must adjust their technique and equipment settings to manage the heat input and minimize warping or burn-through.

We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding.

To weld with flux core, you must set the welding machine to direct current electrode negative (DCEN). This is an important step because most wire feed welders are default set to direct current electrode positive (DCEP) for MIG welding. In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of mastering flux core welding, especially when dealing with delicate 22-gauge sheet metal.

We're using an .030 Select Arc 700GS, which is a gasless flux core wire designed for running on thin sheet metal and galvanized. We will start with a 18 guage sheet metal lap weld.

flux core welding techniques

knob and tube electrical box

kitchen with dark wood cabinet and stainless steel

I recently saw some vids on the new 2012 150 and how its so aerodynamic and has this fully boxed frame concept. How far back did they make 150's with fully boxed frames? Also, what are the pros and cons of said frame?

can you weld sheet metal with flux core|flux core welding for dummies