cnc part programming examples ppt To optimize the efficiency and accuracy of turning operations, CNC turning part programming plays a critical role. In this blog post, we will explore the key aspects of CNC turning part .

1 was here. A shop that can handle all areas of Fabrication,Welding, and Installations. 2- 5'x10' CNC Plasma tab

0 · sample cnc program

1 · manual cnc programming for beginners

2 · free cnc program examples

3 · cnc programming for dummies

4 · cnc programming examples with drawing

5 · cnc mill program example

6 · cnc lathe programming for beginners

7 · beginner level cnc programs examples

Schneider Electric Global. Protect the reliability and efficiency of your processes with our complete range of high quality, standard and universal enclosures, cabinets and boxes.

The document discusses CNC part programming, including manual part programming formats and an example program for turning a part. It covers the input data and .The document provides information on profile milling and contains 6 examples .The presentation included definitions and components of NC, CNC, and DNC . The document provides information on profile milling and contains 6 examples of CNC part programs for milling various components. The programs use G-code commands like G00, G01, G02, G03 as well as M-codes to .

sample cnc program

manual cnc programming for beginners

The presentation included definitions and components of NC, CNC, and DNC systems. It discussed the differences between NC, CNC, and DNC, covering topics like part program input/storage, program modification, .To optimize the efficiency and accuracy of turning operations, CNC turning part programming plays a critical role. In this blog post, we will explore the key aspects of CNC turning part .Define the geometric elements that define the part. Motion statements. Describe the path taken by the cutting tool. Post-processor statements. Apply to the specific machine tool, such as feeds, .

CNC PART PROGRAMMING.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document describes developing part programs for CNC turning, milling, and .

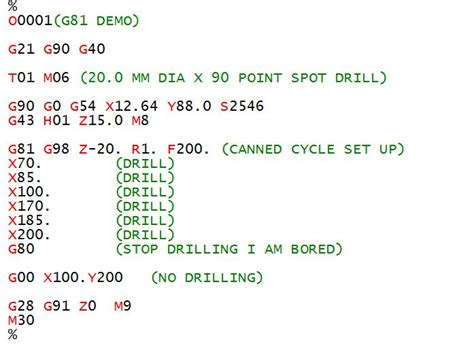

CNC Programming • NC Code • Sample NC Part and Program • M Codes • G Code. NC Code Components • Lines of NC code contain instructions for the machine to follow. • Some of the instructions • prepare the machine • .It is the process of creating instructions for a CNC (Computer Numerical Control) machine to produce precise and accurate turned parts. This blog post aims to provide a comprehensive . 3. Repetitions can be given using the L word or as the first digits of the P word (last four digits are always program number). 4. If a subroutine number is missing in program the simulator will attempt to find a disk file with the .

machining turning aluminium cnc parts pricelist

free cnc program examples

macomb sheet metal fabricating

Title: PowerPoint Presentation Author: Reza Last modified by: Reza Created Date: 1/1/1601 12:00:00 AM Document presentation format: On-screen Show (4:3) – A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on .CNC Lathe & Part Programming by P rof. Jitendra Kumar Lecturer ,Department of Mechanical Engineering G P Vaishali Bihar-844118. CONTENTS • • • • POWERPOINT PRESENTATION NOTES EXAMPLES . Example: N0010 G91 G00 X12.0 Y80.0 N0020 G44 Z-32.0 H023 If we put 0.5mm into H02, Structure A complete NC-program consists of the following elements: Part Program Block Each line of a part program is called a Block. Example N35 G01 X-2 The above block can be explained as follows: N35 Block (Line) Number G01 G- command (Code) to move the cutting tool in linear movement. X-2 The coordinate at X = -26 INTRODUCTION The main difference is that instead of cranking handles to position a slide to a certain point, the dimension is stored in the memory of the machine control. The control will then move (interpolates) the machine to these positions each time the program is run. The operation of the T1-Series Turning Centre requires that a part program be designed, written, and entered .

• Download as PPT, PDF . It provides details on common G-codes and M-codes used in CNC lathe programming along with examples of cycles for facing, turning, taper turning, grooving and multiple operations. Read less. Read more. 1 of 37. Download now. . CNC Program can be divided into three parts.CNC Program can be divided into three parts .

Simple CNC turning programming examples for a typical part. Turning parts are very popular and 2-axis CNC turning programming can be easy for CNC operators and programmers, as the basic operations for completing a part, such as roughing, finishing, drilling, tapping, and threading are less than in CNC milling programming. This document provides an overview of CNC programming and operation skills training at the Government Tool Room and Training Centre in Hassan. It introduces the GTTC and its facilities for CAD/CAM and advanced manufacturing techniques. It then covers the basics of CNC machines, including their typical elements, how they work through G and M . 10. There are four basic types of statements in the APT language: Geometry statements, also called definition statements; are used to define the geometry elements that comprise the part. Motion commands; are used to specify the tool path. Postprocessor statements; control the machine tool operation, for example, to specify speeds and feeds, set .

7. CNC PROGRAMMING CNC is the part program is a set of encoding information, giving co-ordinates and other details to indicate how a tool should move in a relation to a work piece in a machine should perform desirable operation on the job. CNC controls will be the program and execute the operations. The program is prepared by co-ordinate values . 4. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. . 3. Introduction to CNCConventionally, an operator decides and adjusts various machines parameters like feed , depth of cut etc depending on type of job , and controls the slide movements by hand. In a CNC Machine functions and slide movements are controlled by motors using computer programs. The most basic function of any CNC machine is automatic, precise, .

cnc programming for dummies

CNC PART PROGRAMMING.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document describes developing part programs for CNC turning, milling, and verifying on simulation software. It involves: - Co-developing part programs that control machine tool movement and auxiliary functions to .

Cnc Coding Examples CNC Coding Examples: A Deep Dive into G-Code and M-Code Programming . Plan your program carefully: Sketch out your part and plan the toolpaths before writing the code. Use comments: Add comments to your code (using parenthesis; for example (Drilling Operation)) to explain different sections .

M.P- II-UNIT V - CNC MACHINE TOOLS AND PART PROGRAMMING.ppt - Download as a PDF or view online for free . Drilling, reaming, punching, boring and tapping are examples of point-to-point .

By mastering CNC turning part programming and creating impactful PPT presentations, you can effectively communicate the intricacies of this essential machining process. Remember to focus on the key elements, follow best practices, and continuously improve your skills through practice and learning from real-world examples. Cnc Programming Basics - Download as a PDF or view online for free . • Download as PPT, PDF . Aimed to simplify and to reduce programming tasks. Example: G41 can be deactivated by issuing G40 command . 10. Self . 11. • By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining. • All CNC machining begins with a part program, which is a sequential instructions or coded .

Coding For Manual Part Programming Examples Ppt Note: All files are in Word or pdf format. Lab 1 (week 3): CNC Manual Part Programming . Debugging is a major part of CNC part programming, and it is very time consuming. commercial part programs are more efficient and less error-prone than manual debugging, such Sequence or .• All CNC machining begins with a part program, which is a sequential instructions or coded commands that direct the specific machine . Programming Example. Cylindrical Part. Φ 25 Φ 22.5 Φ 17.5 20 Raw Material. Finished Part. 70 30. Programming Example (Cylindrical Part) O0077 N0005 G28 U0.0 W0.0;

The coded instructions are composed of letters, numbers and symbols. Program input device: The program input device is the means for part program to be entered into the CNC control. Three commonly used program input devices are punch tape reader, magnetic tape reader, and computer via RS-232-C communication.

mack kirk roofing & sheet metal ltd

The same is explained later on through examples. Hence the methods of part programming can be of two types depending upon the two techniques as below (a) Manual part programming,and (b) Computer aided part programming. Read more : Bobcad CAM – CNC programming software for Machining ,Turning. example of part programming STANDARD G AND M CODESppt/slides/slide32.xmlÜWKo 7 >»@ÿÃ`{I 8Ò®$[ , ‰›øb;‚¥ gj—Ò.Â% $%ËýõýHîÊÖ£ª 4—^$.9Ïo†3Ãë ëRЊkS(9Œâ 툸LUVÈÅ0ú>ýzÞ ÈX&3&”äÃè™›èãè×_®« [š F¹µÕ Õ2iÎKf>¨ŠKœÍ•.™Å§^´2Íž µ ¤Ý¾h•¬ Qͯ߯æó"å ¨tYriƒ Í ³°ÜäEe iÕ .

CNC Programming The code which controls the CNC machine.. CNC Programming • NC Code • Sample NC Part and Program • M Codes • G Code. NC Code Components • Lines of NC code contain instructions for the machine to follow. • Some of the instructions • prepare the machine • tell the machine where to send the tool • and control .

4. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. . Differentiate between Cartesian and Polar coordinate systems used in CNC programming. 4. Recognize the turning machine axes. . Feed For example, if the lathe is set for a 0.4 mm feed, the cutting tool will travel along the length of the work 0.4 mm for every complete turn that the work makes. So the unit of feed (F) is mm/rev. . Plastic CNC . 4. Cutter Offset Cutter path must be offset from actual part outline by a distance equal to the cutter radius Computer Tasks in Computer-Assisted Part Programming 1. Input translation – converts the coded instructions in the part program into computer- usable form 2. Arithmetic and cutter offset computations – performs the mathematical computations to define .

UPS - Self Service Drop Box (UPS Drop Box) at 578 Hartford Ave in White River Junction, Vermont 05001: store location & hours, services, holiday hours, map, driving directions and more

cnc part programming examples ppt|free cnc program examples