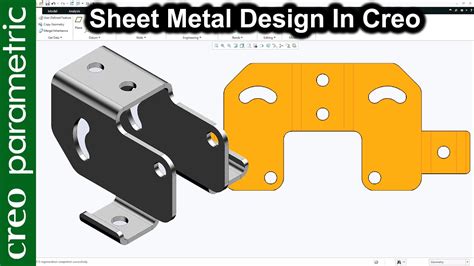

creo parametric sheet metal tutorial The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and . If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

0 · sheet metal in creo parametric

1 · flat vs flange in creo

2 · creo sheet metal tutorial pdf

3 · creo sheet metal practice drawing

4 · creo sheet metal drawing

5 · creo sheet metal design

6 · creo practice sheet metal models

7 · creo 8 sheet metal

Vacuum tables are a powerful tool on a CNC machine, offering dozens of advantages that benefit users of all levels. For the new user, a vacuum table is easy, forgiving, and a fast method to learn. . Each Vacuum Slat is an independent vacuum zone, allowing the operator complete control over where vacuum pressure is applied with the turn of a .

PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0.. sheet metal in creo- tutorial 1planer command in creo parametric

Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the .Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and . A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module.

sheet metal in creo parametric

In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the . In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric.

parts of a sheet metal brakr

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall. PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0.. sheet metal in creo- tutorial 1planer command in creo parametricEvery sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

flat vs flange in creo

Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module.

In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the shell technique to design sheet metal components within an assembly environment.

In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric. In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.

PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..

sheet metal in creo- tutorial 1planer command in creo parametric

Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

Learn how to use Creo Parametric 10.0 to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. A step-by-step guide on how to create the chair from single sheet plate using creo or pro e software inside sheet metal module. In this tutorial, we will learn about the basic techniques related to ‘Sheet Metal’ functionality of ‘Creo Parametric’ by modelling a Cover. In the creation .

patch panel junction box

Explore the fundamentals of sheet metal creation in Top-Down Assembly mode using the shell technique in this 29-minute tutorial for Creo Parametric 9.0. Learn how to effectively utilize the shell technique to design sheet metal components within an assembly environment.

creo sheet metal tutorial pdf

parts of cnc machining center

pdz metal fabrications

Was going to ask if you sandwiched a thermal barrier between the railing and the heat shield? Would think that the metal could get hot if you cooked on the grill long enough. That's was going to be my comment. We have an almost identical scenario at my sister's house.

creo parametric sheet metal tutorial|creo practice sheet metal models