bending sheet metal rules This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Wholesale CNC machining small parts, Get a Quote now! The CNC machining service is provided by Fathom Precision, an experienced small-part machining manufacturer, and also for small metal and plastic parts for prototype and production with high quality and precise product throughput.

0 · sheet metal guidelines pdf

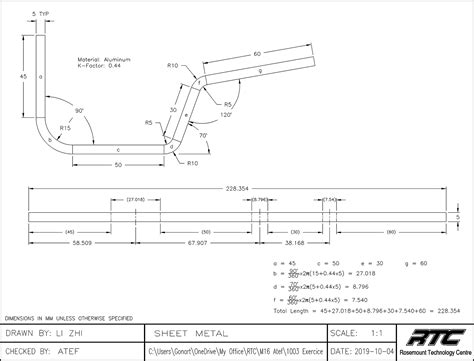

1 · sheet metal dimensioning standards

2 · sheet metal bending radius chart

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · sheet metal bend tolerance chart

6 · sheet metal bend allowance chart

7 · bending sheet metal by hand

Use the power of Alibaba.com, one of the largest B2B marketplaces in the world to find the right wholesale milling auto parts for the materials and designs you are working with. These cnc machining shops can handle all requirements including milling, grinding, drilling, cutting and more.

sheet metal guidelines pdf

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and . In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. .

In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard .Bending is a process whereby a force is applied to sheet metal which causes it to bend at an angle and form the desired shape. Bends can be short or long depending on what the design requires. This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.

An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts. Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.

In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard thickness. Manufacturer provides sheets thickness in gauge.Bending is a process whereby a force is applied to sheet metal which causes it to bend at an angle and form the desired shape. Bends can be short or long depending on what the design requires.

This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.

An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts.

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.

sheet metal dimensioning standards

In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard thickness. Manufacturer provides sheets thickness in gauge.Bending is a process whereby a force is applied to sheet metal which causes it to bend at an angle and form the desired shape. Bends can be short or long depending on what the design requires.

This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.

roofing metal sheets

Telescopic cover are designed to protect slideways and precision machine components from sharp /hot chips, sparks, dropped tools, cutting oils and coolant etc. Telescopic steel covers .

bending sheet metal rules|sheet metal bending chart