benefit cnc machine CNC (Computer Numerical Control) Manufacturing is a modern methodology that prioritizes efficiency and precision across various industries. This technology employs .

To fix warped sheet metal after welding, you can follow a few steps. Firstly, use a torch or flame to heat the warped area of the sheet metal. Once heated, rapidly cool the area with water or compressed air to help reposition the metal. Next, combine excessive heating with hammering or striking the sheet metal in the opposite direction of the warp.

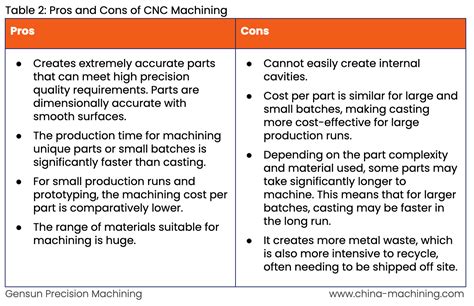

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

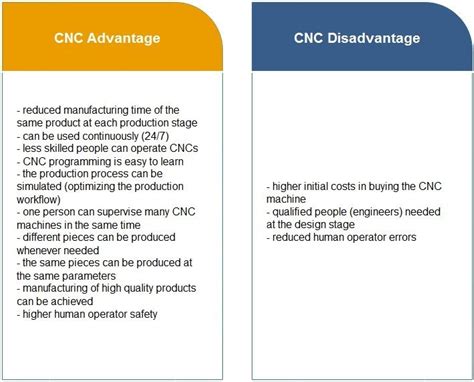

7 · cnc advantages and disadvantages

Lakeside Autobody focuses on measuring, cutting, fitting, and welding homemade, DIY automotive sheet metal patch panels.Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See more

pros and cons of machining

CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits . This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive.

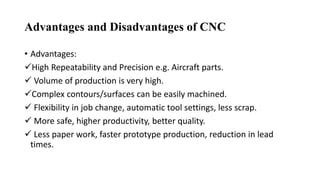

Explore 15 benefits of CNC machining and milling: precision, efficiency, cost-effectiveness, material versatility, and safety features. CNC (Computer Numerical Control) Manufacturing is a modern methodology that prioritizes efficiency and precision across various industries. This technology employs .CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the .

CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries. CNC machining is a form of manufacturing that uses computer-controlled machine tools to create parts and products. The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency.

Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive.Explore 15 benefits of CNC machining and milling: precision, efficiency, cost-effectiveness, material versatility, and safety features. CNC (Computer Numerical Control) Manufacturing is a modern methodology that prioritizes efficiency and precision across various industries. This technology employs computerized instructions to fabricate precise elements, ranging from intricate machine parts to customized tools.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.CNC machining emerges as a beacon in this journey, offering unparalleled advantages that have transformed production processes across industries. Before we delve into the specifics, let’s set the stage by understanding why CNC machining is .

One of the primary benefits of CNC machining is its exceptional precision and accuracy. CNC (Computer Numerical Control) machines are capable of producing parts with incredibly tight tolerances, ensuring that each piece meets the exact specifications of the design.

CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries. CNC machining is a form of manufacturing that uses computer-controlled machine tools to create parts and products. The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency. Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive.Explore 15 benefits of CNC machining and milling: precision, efficiency, cost-effectiveness, material versatility, and safety features.

CNC (Computer Numerical Control) Manufacturing is a modern methodology that prioritizes efficiency and precision across various industries. This technology employs computerized instructions to fabricate precise elements, ranging from intricate machine parts to customized tools.

disadvantages of cnc milling

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.CNC machining emerges as a beacon in this journey, offering unparalleled advantages that have transformed production processes across industries. Before we delve into the specifics, let’s set the stage by understanding why CNC machining is .

how to install a remodel junction box

In your receptacles, you're getting voltage between the hot wire and the box because the box is grounded by means of the metallic conduit back to the panel. If you have a main breaker panel serving as the first service disconnect means, then the panel should utilize the bonding jumper. They have a heck of a lot longer runs going than that.

benefit cnc machine|cnc milling advantages and disadvantages