how to roll a sheet metal cone Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . I would like to find a way to mount those weatherproof boxes to a length of unistrut to allow for future addition/modification without having to drill masonry over and over. Below is a sketch of what I'd like to do:

0 · sheet metal layout cone

1 · sheet metal cone rolling calculation

2 · sheet metal cone roller

3 · sheet metal cone development formula

4 · sheet metal cone calculator

5 · how to layout a cone

6 · cone weight calculator in kg

7 · cone layout calculator

Does the Code allow a PVC box such as a 12 x 12 Carlon box to be used as a junction box when buried face up (cover exposedf) as long as it is not exposed to physical .

sheet metal layout cone

Rolling a Long Cone from Sheetmetal. Ron Covell. 207K subscribers. Subscribed. 4.4K. 134K views 1 year ago. See how to roll a long cone from 16-gauge (1.6mm) sheetmetal. .more.. Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S.

How to roll a cone on a steel slip roller. Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is.

adding junction box to existing pvc conduit

Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size . Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Sheet metal rolling is another method of bending steel, but in this case the goal of manufacturing is to achieve a rounded circular bend, under specific radius, rather than a V-shaped angular form. Some of the main . I have a background in structural steel drafting, so laying out the pattern for a cone is no issue, just how to use a piece of machinery to form it. You can make a cone with a .

Rolling that cone will be a trick especially so the ends lie on the surface of the cone. There's a sheet metal trick to fix that. What is it? Video title: How to Roll a Cone – Midland Fabrication In this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. The cone is stage 1.

When you need to roll sheet or thin flat bar stock into an arc, you need a rolling machine, also known as a slip roll. If you’ve priced these lately, you’ll know that they can be rather.Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number .

JD goes over this BEAST of a Slip Roll and Why you want one in your garage! MORE INFO: https://www.eastwood.com/eastwood-heavy-duty-50-inch-slip-roller-with-.The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . "Without . In this video I make a sheet-metal slip roll for shaping cones and cylinders. The tool I made is quite small, but yet very rigid due to the variable width de. Learn how to use a Slip Roller and form perfect sheet metal rolls.Roll sheet metal, roll cones and more with a slip roller.00:00 Intro00:24 How a Slip Roller.

#MetalFabricationTips #FabricationTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows a great tip for rolling metal in small diamete. ZVX bending machine to roll metal sheet into a conecontact us: [email protected]

Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", .

Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted several weeks ago and you .

Learn how to form a cone by cone bending on Revolution Machine Tools R-SMART 6-709 4 Roll Plate Roll.Presented by Atakan NerminerTo learn more visit http://w. Learn how to roll sheet metal with ease using these simple steps and tips from expert inventors. Master this skill and take your metalworking projects to the. Learn from Avon Lake Sheet Metal experts about fabricating high-quality sheet metal cones for industrial and commercial applications. Skip to content. Call Us Today 440-933-3505. Search. . or by using a cone-rolling machine. Professional sheet metal fabrication companies have the expertise and specialized equipment necessary to form the cone . When you need to roll sheet or thin flat bar stock into an arc, you need a rolling machine, also known as a slip roll. If you’ve priced these lately, you’ll know that they can be rather.

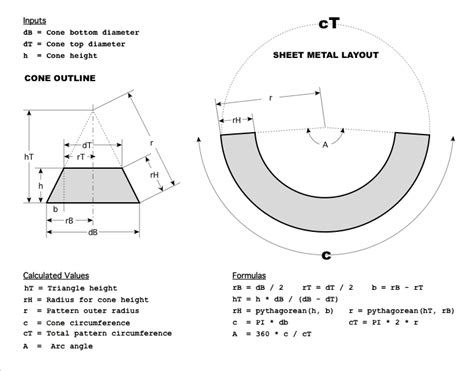

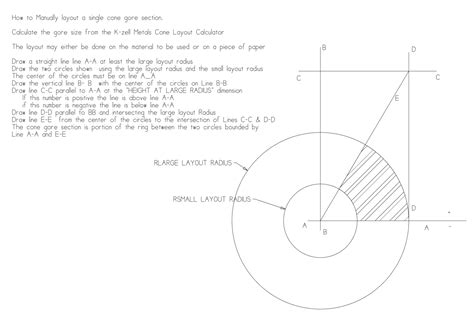

Step 2: Mark and Cut the Sheet Metal . Now that you have your dimensions, it's time to mark and cut the sheet metal. Using a compass or trammel, draw a large circle with a radius equal to the slant height (L) on the sheet metal. Then, draw a smaller circle within the larger circle, with a radius equal to the top radius (R2). If you do have a metal rollers, then.yay! But if you don't have such a tool, sometimes it's nice to see how it can be done with other machines/tools - such. The 70×3000 sheet rolling mill of a certain unit is used to roll 60×2000 blast furnace cones with method 6. Due to the insufficient strength of the connecting bolts between the upper and lower parts of the transmission side .

Exercise 23 - Sheet Metal - Conical parts and text. Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material.You can find cone calculators online,.

Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I’m here to alleviate your worries and provide you with the correct workflow. I typically like to start my first sketch on the Top Plane. Using my sheet metal open sketch technique, we can draw an arc and its construction lines. With the radius (or diameter) dimension . This will give you the length of the center line you need from the top of the cone to the intersecting point (A) . Western Sheet Metal, 2406 Hinton Dr, Irving, Texas, 75061 Office: 972-438-7742 Fax: 972-438-2996 Email: [email protected] Email: [email protected]. Hours:

Exercise 21 - Sheet Metal cylinders, and linear patterns. WATCH FULL VIDEO HERE https://youtu.be/gHYrnai5Q7c@JetManJoe Easiest way to Form Sheet Metal Cone with a DIY Snubber Attachment.Make your own simple Snubber .

I've used a slip roll to form flats and sheets into circular shapes before, but I'm wondering what it takes to make a cone. I don't have a slip roll currently, nor do i have access to one at the moment, so i can't do any testing, but can you form a cone with one or does it require a special type of roll? to make a cone, one edge of the sheet must pass through at a far greater .

Learn how to layout a cone in sheet metal Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is.Learn how to roll sheet metal in Autodesk Inventor with step-by-step instructions and tips for creating curved designs and geometric shapes with precision. P. Kevin uses a hammer to adjust and even up the ends of the metal. Now he’ll come in with his TIG welder and tack the metal together and remove the hose clamps. He can then add a few more tacks, and weld the aluminum cone inside for greater strength. If he needs to, he can further shape the aluminum piece on his anvil or even just adjust it by . Pretty much any (larger) sheet metal shop could knock up an oblique cone in 2 mm st/st. A set of 75mm rolls would be able to roll it, although it would be tiring to make a lot of them. RE: rolling an eccentric cone

adjustable base bed electrical box

Boxing gloves are a vital piece of equipment for combat-minded athletes. Train round after round with these top mitts from Hayabusa, Sanabul, Everlast and more.

how to roll a sheet metal cone|how to layout a cone