diy cnc rack and pinion parts Additionally, since a gear reduction is almost mandatory for a rack and pinion system, I decided to make this system compatible with NEMA 23 motors to take advantage of . $151.46

0 · stepper motor rack and pinion

1 · cnc router rack and pinion

2 · cnc rack and pinon system

3 · cnc rack and pinon drive

4 · cnc rack and pinion drive

Steel frame homes are constructed in the same way as wood-frame homes, but the materials are different. Instead of studs made of timber, metal I-beams form the supports of the structure. Steel framing can be easily cut with a metal saw, blow torch, or .

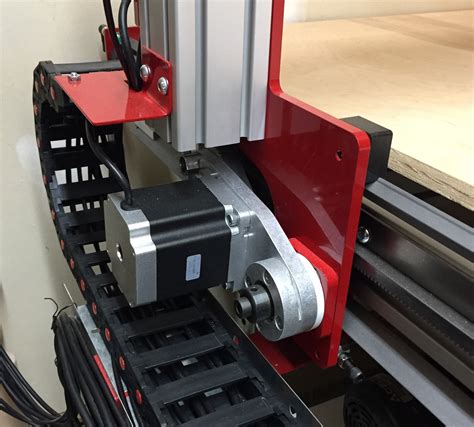

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a .Unlike most DIY machines, this build features a custom rack and pinion drive on the X/Y axis. The gear racks are 20* pressure angle/20 pitch, and were CNC cut at my day job from Delrin. The . I'm working on a design for a new CNC router build. I've been working on researching a rack and pinion drive system and hoping for some feedback. I'm building a 4' x .

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, .

Additionally, since a gear reduction is almost mandatory for a rack and pinion system, I decided to make this system compatible with NEMA 23 motors to take advantage of . Build in ' Cartesian Style CNC ' published by mytechno3d, Jan 5, 2020. Build Complete! I need for my workshop a big and heavy cutting table who can handle both router . This instructable is more of a documentation of how I build my CNC and is not to be mistaken as a tutorial for buidling a CNC. The initial target of my build was to make a large .

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.Unlike most DIY machines, this build features a custom rack and pinion drive on the X/Y axis. The gear racks are 20* pressure angle/20 pitch, and were CNC cut at my day job from Delrin. The (NEMA 23) pinion/pulley system comes from AVIDCNC.com. I'm working on a design for a new CNC router build. I've been working on researching a rack and pinion drive system and hoping for some feedback. I'm building a 4' x 8' to 5' x 10' table. I like what I've seen the DamenCNC anti backlash rack and Pinion system.In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

Additionally, since a gear reduction is almost mandatory for a rack and pinion system, I decided to make this system compatible with NEMA 23 motors to take advantage of the popular and easy to setup Gecko G540 drive.

stepper motor rack and pinion

Build in ' Cartesian Style CNC ' published by mytechno3d, Jan 5, 2020. Build Complete! I need for my workshop a big and heavy cutting table who can handle both router and plasma torch . Working area : 2250mm x 1300mm . Until now , i never use rack and pinion drive , it will be the first try for me. This instructable is more of a documentation of how I build my CNC and is not to be mistaken as a tutorial for buidling a CNC. The initial target of my build was to make a large format CNC router which does not compromise on the quality and functionality.

sheet metal fiber laser

How to choose and calculate spring load properly? The goal of the spring is just to keep the pinion gear fully engaged with the rack at all times, even under maximum loads. Im working on building a gantry rack and pinion cnc with servo motors. Ill be milling steel and aluminum parts and is 10;1 gear ratio or for the 750w motors, also a servo with rotate the workpiece horizontally at 10:1, iIdont need to move it at insane spe8ds though. Any thoughts on this as im am using freecad. thanksProducts On Sale. Black Acrylic Sheet Board Glossy on Both Sides. Rated 0 out of 5. CAD$ 1.58 – CAD$ 11.09 CNC Spring Collet Set ER11, ER16, ER20, ER25

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.Unlike most DIY machines, this build features a custom rack and pinion drive on the X/Y axis. The gear racks are 20* pressure angle/20 pitch, and were CNC cut at my day job from Delrin. The (NEMA 23) pinion/pulley system comes from AVIDCNC.com. I'm working on a design for a new CNC router build. I've been working on researching a rack and pinion drive system and hoping for some feedback. I'm building a 4' x 8' to 5' x 10' table. I like what I've seen the DamenCNC anti backlash rack and Pinion system.

cnc router rack and pinion

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood. Additionally, since a gear reduction is almost mandatory for a rack and pinion system, I decided to make this system compatible with NEMA 23 motors to take advantage of the popular and easy to setup Gecko G540 drive.

Build in ' Cartesian Style CNC ' published by mytechno3d, Jan 5, 2020. Build Complete! I need for my workshop a big and heavy cutting table who can handle both router and plasma torch . Working area : 2250mm x 1300mm . Until now , i never use rack and pinion drive , it will be the first try for me. This instructable is more of a documentation of how I build my CNC and is not to be mistaken as a tutorial for buidling a CNC. The initial target of my build was to make a large format CNC router which does not compromise on the quality and functionality.

How to choose and calculate spring load properly? The goal of the spring is just to keep the pinion gear fully engaged with the rack at all times, even under maximum loads.

Im working on building a gantry rack and pinion cnc with servo motors. Ill be milling steel and aluminum parts and is 10;1 gear ratio or for the 750w motors, also a servo with rotate the workpiece horizontally at 10:1, iIdont need to move it at insane spe8ds though. Any thoughts on this as im am using freecad. thanks

cnc rack and pinon system

sheet metal flooring

sheet metal fabricators tulsa

Genmitsu CNC Machine PROVerXL 6050 Plus for Metal Wood Acrylic MDF Carving, GRBL Control, 3 Axis Milling CNC Router Machine, Hybrid Table, Working Area 600 x 500 x 115mm (23.62" x 19.69" x 4.53") 4.6 out of 5 stars

diy cnc rack and pinion parts|cnc rack and pinion drive