what does a cnc machine make A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling . Mesh fabric is a lightweight textile with an open weave structure. It features thousands of tiny holes. It's primarily made from synthetic materials but also available in natural fibers. Mesh fabric is famous for its breathability, moisture-wicking properties, and durability.

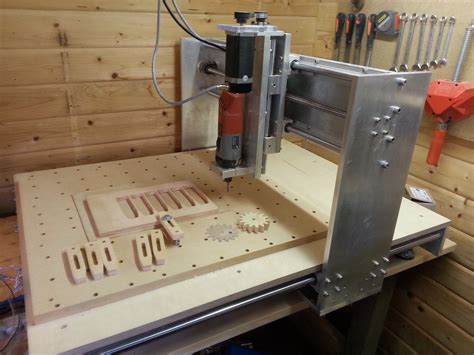

0 · make your own cnc machine

1 · homemade cnc machine plans

2 · homemade cnc machine

3 · do it yourself cnc machine

4 · build your own cnc mill

5 · build your own cnc machine

6 · build your own cnc

7 · build own cnc machine

Produces straight-line cuts on flat metal stock, eliminating sheet metal waste and ensuring a clean edge. Uses a mixture of water and abrasives at high pressures to make precise cuts without heat, ensuring no metal warping. Uses concentrated beams of light to melt, burn, or vaporize material, providing precise and clean cuts.

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or . Essentially, it’s a technology that automates machine tools by using computers to control them. Instead of being manually operated by hand, CNC machines rely on a set of pre .

A CNC machine tool is an automatic machine equipped with a program control system, capable of solving processing problems for complex, precise, small-batch, and multi .A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling .CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .

The emergence of CNC machine tools. The development of numerical control (NC) machine tools began in the United States. In 1948, Parsons Co. completed a task to manufacture sample check plates for the .How Does CNC Punching Work? CNC Punching Process. Setup the Machine. We first set up the CNC machine. The first step is configuring the punch and die set based on specific design requirements. It’s essential to have the correct .In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process.The code determines everything from the movement of the cutting head and the part to spindle .

CNC Machines can do many things. Today computer technology can be put on just about machine imaginable. The CNC replaces the human interface needed to move machine parts to get the desired result. Today’s CNC’s are capable of starting with raw material, like a block of steel, and making a very complex part with precise tolerances and .If you make one machine to do both, you're going to wind up with something that is okay (if you're lucky) at everything and is a complete compromise. . Most full size vertical CNC machines are essentially variations on a scaled up Bridgeport style "C" shaped frame with a table moving under the spindle column. The tabletop mills are scaled . This is where the real time and effort is saved. No tracing or sawing. Just sit back and sip a tasty beverage while the machine does the work. Then when your next friend wants a cutting board of their own, all you have to do is make another blank, setup the CNC router and hit “cycle start” again. CNC Machines are great!

The Wooden showcases types of jewelry that you can make with a CNC machine. 25. Tree ornaments. In the lead-up to the holiday season, there’s a huge demand for unique tree ornaments. While it might be easy for buyers to find standard bulbs and angels, originality is hard to come by, opening niche possibilities. .

make your own cnc machine

What does a CNC machine do? A CNC machine automates the control, movement, and precision of machine tools using preprogrammed computer software. This technology is widely used in manufacturing to machine metal and plastic parts with high accuracy and efficiency. By embedding software directly into the tools, CNC machines streamline the . CNC machines are used in areas that require precision and accuracy as well as repetitiveness. Long ago, the precision required for tasks such as bolt manufacturing could only be accomplished by humans. They are machines that are more accurate than humans and can repeat the operation multiple times. CNC machines are capable of producing nearly .A CNC (Computer Numerical Control) Operator is responsible for running CNC machines that cut, shape, and finish metal and other materials. They input instructions into the machine, ensure materials are properly loaded, supervise the cutting process, make adjustments as necessary, and verify the final product meets specifications. Cautions. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine.There are three stepping motors and one spindle motor on the machine. Therefore, the current of the CNC machine is very large in the process .

Now that you can get small, desktop CNC machines, it is more accessible than ever to make beautiful wood projects at home and sell them for a profit online. Below you will find some amazing CNC projects for beginners and more advanced woodworkers. All of them are top sellers on Etsy and at craft fairs around the country. Over the years CNC machining has grown to become an integral part of many industries including automotive, aerospace, medicine, manufacturing, food, sports, and fashion. Hundreds of thousands of companies are using CNC machines to create both simple and complex products that would have been impossible to create in the absence of these machines.

As of November 01, 2024, the average annual pay of Cnc Machine Technician in the United States is ,676.While Salary.com is seeing that Cnc Machine Technician salary in the US can go up to ,324 or down to ,389, but most earn between ,815 and ,679.Salary ranges can vary widely depending on many important factors, including education, certifications, .

How Does a CNC Lathe Machine Work? Image Credits: marvo.eu. A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. These lathes contain different .A machinist operates computer numerically controlled (CNC) machine tools, such as lathes and milling machines, to cut and produce precision parts for machines, instruments, and tools. Machinist repair or produce parts using both manual and . Keep reading to learn the ins and outs of CNC machining. What Does a CNC Machine Do Exactly? CNC machines are now used around the entire world in pretty much every type of industry. CNC machines have the . CNC machines, or Computer Numerical Control machines, are manufacturing marvels that integrate accuracy, speed, and regularity based on computerized systems.The machinery is used across different sectors, such as aerospace and automotive, for making intricate components that are of high quality.

What is CNC programming: CNC programming is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece.; How to learn CNC programming: The best way to learn CNC programming is to find a CNC shop that is hiring and start as a machine tool operator.You can also watch online tutorials and use . The CAD file is exported to a CAM (Computer Aided Manufacturing) software package that contains a range of tools to convert the 3D model into a set of instructions that can be understood by the CNC machine. CAM software is normally used by CNC machine operators to generate G-code. At the end of the process, a G-code file is saved to the machine.FAR better paying, less overall work and way less stress. Applications engineer is also a great way to work in CNC, make $$$, and travel the world. . Do it right, then do it fast. My attitude was "The machines could press their own buttons and shit parts into a box - my first job is quality." If a shop doesn't appreciate that then leave. What kinds of CNC machines do you own? CNC Mills and Routers (really the same thing in many respects) make up the majority at about 70% with 3D Printers and Lathes following. I would’ve expected the Lasers and Plasma tables to be a little higher percentage and the lathes a little lower, but this is what’s being reported.

CNC lathe is a machine tool that shapes metal by rotating it against a cutting tool.The workpiece is usually held in place by either one or two centers. CNC router is a power tool that uses a circular cutting bit to make decorative, artistic, and functional cuts in wood, stone, plastic, and other materials.; CNC milling machine is a machine used for shaping solid materials into . Key Takeaways: Understanding CNC Machines: Grasp the fundamental concepts behind CNC machinery.; Types of CNC Machines: Familiarize yourself with the various machines available in the market.; Factors to Consider Before Buying: Learn what to look for when purchasing a CNC machine.; Safety and Maintenance: Understand the importance of safety .

CNC machines can operate on multiple axes, which enables them to create complex shapes and make accurate cuts with high precision. This multi-axis capability allows for intricate designs and detailed work, making CNC machines highly versatile in manufacturing.Cnc Machinist Salaries by State. What is the average annual salary for a Cnc Machinist job by State? See how much a Cnc Machinist job pays hourly by State. Washington is the highest paying state for Cnc Machinist jobs. Florida is the lowest paying State for Cnc Machinist jobs.

homemade cnc machine plans

This includes perhaps the most important core business system at many metal fabricators: the enterprise resource planning (ERP) platform. What Is ERP?

what does a cnc machine make|homemade cnc machine plans