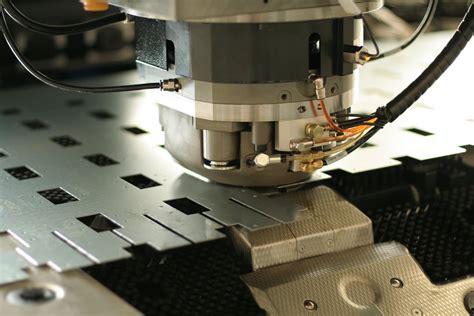

brass stamping sheet metal fabrication Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. This article will delve into the definition of sheet metal stamping, how it works, and the equipment involved.

Need a drawing or design ? We can help. Custom dollies and tables made per your specs. Custom Water Tanks small or large. Custom flashing or downspouts for the roofing industry. Maintenance repair for dozens of local companies. Custom fabricate a meter base cover for your home or bld. Metal dutch door shelves , kick plates of any size for doors.

0 · sheet metal stamping process

1 · sheet metal stamping

Old work electrical boxes are used when you need to add an electrical box to walls that are closed in or covered with drywall. These boxes are designed to clamp into the drywall .

Hot Stamping: The brass sheet is heated before stamping. Heat makes brass malleable and allows for more intricate designs. Ideal for drawing complex and profound forms. It has a smoother finish thanks to less internal stress. Cold .Deeco Metals is your reliable and trusted source for custom brass metal stamping services. Our full-service custom sheet metal stamping and fabrication services are performed using CAD/CAM designed tools that provide the precision .Hot Stamping: The brass sheet is heated before stamping. Heat makes brass malleable and allows for more intricate designs. Ideal for drawing complex and profound forms. It has a smoother finish thanks to less internal stress. Cold Stamping: Do not exceed room temperature. For thinner brass sheets or parts with less complexity. Brass stamping entails different forming processes that transform the brass alloy into the desired shape. Some of the common brass stamping processes include: Blanking Brass. Involves cutting out the desired brass part shape with the hole diameter and edge-to-hole spacing important parameters.

Deeco Metals is your reliable and trusted source for custom brass metal stamping services. Our full-service custom sheet metal stamping and fabrication services are performed using CAD/CAM designed tools that provide the precision required for complex parts.Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. This article will delve into the definition of sheet metal stamping, how it works, and the equipment involved.When you need high quality brass stampings, trust the experienced team at Winco Stamping to provide top-notch parts on time and on budget. We produce custom short run and medium run stamped parts with our in-house tooling process. Brass is .At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication.

In this comprehensive guide, we'll delve into the world of brass stamping and sheet metal fabrication, exploring the various techniques, tools, and tips that will help you master this art.TenRal is pleased to offer custom-made brass fabrication services, including cutting, forming, and welding. We are proud of our extensive use of brass sheet metal in various industries!All-New can work with any sheet metal stock from .001-.250” thick, including, steel, stainless steel, copper, brass, aluminum and even rigid plastic. We can fabricate parts as large as 48”x 48”. Our 40,000 sq. ft. state-of-the-art production facility allows us to manufacture your parts to tight tolerances, with production runs from 25 to 1,000,000.Our goal is 100% customer satisfaction, providing ISO 9001:2015 certified brass metal stamping resulting in cost-effective solutions with timely turnaround. Material Types: Coil, sheet metal, and metal blanks. Stamping Processes: Mechanical progressive and hydraulic deep draw brass parts.

Hot Stamping: The brass sheet is heated before stamping. Heat makes brass malleable and allows for more intricate designs. Ideal for drawing complex and profound forms. It has a smoother finish thanks to less internal stress. Cold Stamping: Do not exceed room temperature. For thinner brass sheets or parts with less complexity. Brass stamping entails different forming processes that transform the brass alloy into the desired shape. Some of the common brass stamping processes include: Blanking Brass. Involves cutting out the desired brass part shape with the hole diameter and edge-to-hole spacing important parameters.

Deeco Metals is your reliable and trusted source for custom brass metal stamping services. Our full-service custom sheet metal stamping and fabrication services are performed using CAD/CAM designed tools that provide the precision required for complex parts.Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. This article will delve into the definition of sheet metal stamping, how it works, and the equipment involved.When you need high quality brass stampings, trust the experienced team at Winco Stamping to provide top-notch parts on time and on budget. We produce custom short run and medium run stamped parts with our in-house tooling process. Brass is .At Pacific West America, Inc. we provide custom metal stamping, CNC machining, printed circuit boards, and membrane switches. Utilizing state of the art machinery, we offer precision metal fabrication and sheet metal fabrication.

In this comprehensive guide, we'll delve into the world of brass stamping and sheet metal fabrication, exploring the various techniques, tools, and tips that will help you master this art.TenRal is pleased to offer custom-made brass fabrication services, including cutting, forming, and welding. We are proud of our extensive use of brass sheet metal in various industries!All-New can work with any sheet metal stock from .001-.250” thick, including, steel, stainless steel, copper, brass, aluminum and even rigid plastic. We can fabricate parts as large as 48”x 48”. Our 40,000 sq. ft. state-of-the-art production facility allows us to manufacture your parts to tight tolerances, with production runs from 25 to 1,000,000.

steel box header

sheet metal stamping process

sheet metal stamping

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

brass stamping sheet metal fabrication|sheet metal stamping