cnc machining software does g code for you Mastercam. Mastercam is the most popular Computer-aided-manufacturing software used in the manufacturing industry. It provides an extensive set of tools for toolpath generation . Roof and building specifications often use “gauge” when stating the required material thickness. A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof.

0 · g code writing software

1 · g code programming software download

2 · g code drawing software

3 · free g code maker

4 · free g code generator

5 · free g code editor software

6 · best free g code generator

7 · best cnc g code software

I need to do some machining on very long parts (approximately 9' long) which is much longer than the X travel on my CNC machines. I can run them on an open-sided bed mill so I can hang the parts off side of the machine.

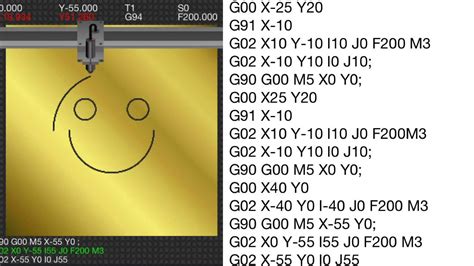

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. Once you have your g-code, you use your CNC controller software to run the machine and create your model from your chosen material. Some software allow you to edit . G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to . Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M .

Mastercam. Mastercam is the most popular Computer-aided-manufacturing software used in the manufacturing industry. It provides an extensive set of tools for toolpath generation .

G-code is the primary language for controlling CNC machine movements, defining exactly how and where the machine’s tool moves to shape a part. Each command in G-code is . Using Cartesian coordinate systems, G-code instructs the CNC machine tool on the workpiece’s actions and location. Each command begins with an alphanumeric code, starting with G or M, enabling operators to automate . This is a really impressive all-in-one 3018 CNC software solution that allows you to create designs, turn them into g code, and control your machine. In fact, it’s one of the few CNC 3018 software that offers all three .

In CNC machining, G codes convert complex operations into structured tasks. The use of standardized codes ensures consistency and optimal performance. . The specific codes available can vary depending on the CNC machine manufacturer and control software. Generally, the basic G-codes cover movements (like G0 for rapid positioning and G1 for .

A: The primary function of CAM software is to prepare G-code. The software is used to translate the models into machine-comprehensible G-code, which is executed by CNC devices. This alleviates G-code programming and .History of G and M Codes in CNC Programming The Development of CNC Machining in the 1950s. The story of G and M codes begins with the birth of CNC machining. In 1952, John T. Parsons collaborated with IBM to develop the first numerically controlled machine tool. This groundbreaking invention laid the foundation for modern CNC machining. When it comes to CNC or computer numerical control machining, one must understand G-code for machine precision and optimal operations in the manufacturing industry. Amongst the several G codes available, the G05 command is unique because of its contribution towards motion control improvement and high-speed machining center realization. A python library for programatically generating g-codes for CNC machining - fcorthay/g-code-lib

What is G-code for CNC Programming and Machining? What is G code? G-code is the most common CNC programming language used in CAM (Computer Aided Manufacturing) software to control automatic machine tools, which is also known as RS-274. G code is the instruction in the CNC program, which is referred to as the G command.Because some operations that you do on a cnc machine are beyond what your CAM software is capable of. For job shop type stuff, where seconds don't matter, you can post your code, run it, and move on to the next part. . I've got a background in software development so G-Code is extremely straightforward comparatively, and if the codes .You can run a G code program in either metric or imperial but Candle will only show millimeters in the ‘state’ readouts. There does not appear to be any way of changing this. Running an imperial G code program will produce a correctly sized project as long as the G20 code (inches) is specified in your program. Setup your Cnc Machine P: Commands G code for CNC to jump in delayed or in time; Other structures of G code for CNC are dependent on the abilities of the machine. The code might add extra direction coordinates for 4- or 5-axis equipment. The Most Common G Code. You can categorize G code for CNC machine into various groups depending on its functions. The categories .

CAM Software:CAM software, on the other hand, takes the CAD-generated design and translates it into machine-readable instructions (G-code) that CNC (Computer Numerical Control) machines can execute. CAM software defines toolpaths, speeds, and feeds necessary for machining operations such as milling, turning, and cutting.

g code writing software

g code programming software download

G-code (Geometric code) is a programming language by which a computer controls the movements of a CNC machine or a 3D printer. It defines the parameters like RPM of the spindle, feed rate, coordinates of the toolpath, tool information, fan speed, nozzle and bed temperature, etc. These parameters vary depending on whether you are working with a CNC .

To get more from your CNC machine, you can also read our guide on the best CNC software. Best Free CNC Simulator Software 1. CAMotics – Powerful yet user-friendly free CNC simulator . With this CNC simulator software, you can verify G-code commands and analyze the real life machining results. Eureka software has been around for 20 years and .

CAM software generates the G-code instructions that the CNC machine can understand and execute. The CNC machine reads and follows the G-code instructions, performing the machining operations. In essence, CAM software serves as the bridge between a CAD design and the physical manufacturing process, ensuring that the CNC machine .

G-codes work to control CNC machine tool movements, while M-codes oversee various functioning processes like coolant flow or tool change. The combination of M-code and G-code commands forms a complete CNC .

Made in the USA - Season 2 Episode 6: Why, and How, Hardinge is Reshoring Machine Tool Production In this episode of Made in the USA, several executives and senior staff at Hardinge give their first-person account . A: G06 CNC code is not a part of the standard language used in CNC programming. Generally, G codes are utilized for various purposes in CNC machines, including tool changeovers, movements, and cutter compensation. Q: How does G-code work on a CNC machine? A: In the field of computer numerical control (CNC), machining uses g-code more . A CAM system isn’t complete without a full post processing engine. Once the toolpath is produced and simulated for accuracy, the software should allow the operator to choose the post processor for their CNC machine to generate the accurate G-Code program to support the machine tool. There can be many variations of g-code. Training as a CNC machinist might seem a bit daunting. There’s a lot to learn, and terms like “g-code programming” or “Cartesian coordinate systems” can sound intimidating. Not to mention that machining itself is a complex and growing field, touching on everything from manufacturing and heavy industry to advanced robotics. Faced with a heavy learning

This lesson is part of a online course for CNC router owners available here:https://gcodetutor.com/cnc-router-programming.htmlThe best way to learn G-Code is. Wow thank you guys for putting the work into helping me, I've read everything closely. The G-code I want to write is for a Milltronics machine with Centurion 7 control. I'll figure out the specifics through the manual and maybe a chirp here or there. Thank you for the extensive G-code experience, though. This will be a major help in getting .

Precise software control is necessary for CNC machining equipment to operate at maximum efficiency. For equipment processing control, Lunyee's desktop CNC engraving mostly employs Candle and LaserGRBL. They assist in running and maintaining the engraving machine. What Software Do I Need To Run a CNC Router? There are three types of software you need for CNC router work: CAD software – computer-aided design software is the first type of software you need to use to create your designs.; CAM software – you then need computer-aided manufacturing software to convert your design into g-code and generate a toolpath for your . A step-by-step guide on implementing G25. Machine Preparation: Make sure that the CNC machine is turned on and calibrated correctly before starting the G25 operation. G25 Input: On your program, type in the command ‘G25’ at a suitable point which is usually before rapid or linear movement executions. Position Verification: Check if the current position is .

A G-Code simulator is a type of software tool that provides a virtual representation of a CNC machine’s tool path made by following the instructions in a G-Code file. They range from simple simulators that output a single image of the tool path to complex tools that can detect collisions and plot the path in 3D. Mentioned to my boy that it would be nice to be able to have both progs for a dual path control up on the screen at once (Which can be done currently with Notepad) but with them synch'd via wait codes to make it much easier to follow visually. He said that he could write a program for that if I. G-code depends so much on machine and tools used so unless you have your own machine, you need a really good reason to dive into this. . So far Mecsoft and CNC Software, and cost me an arm and a leg . lander (CAD CAM CNC) March 22, 2023, 7:37pm 9. Martin Siegrist: G-code depends so much on machine and tools used so unless you have your .

g code drawing software

free g code maker

I would like to install some outlets under my house soffits for Christmas lights and I have a few questions and would like to ideas on how to do this. My soffit is fully in closed and my first thought was to install old work junction boxes but since this is going to be outside and sure that the box has to be weatherproof.

cnc machining software does g code for you|g code drawing software