what is cnc milling machine November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady . The Legrand Wiremold 700 series raceway is ideal for surface mounting small amounts of electrical wiring or communication cables. Surface metal raceway allows you to add fixtures and outlets without disturbing the drywall, plaster or insulation in your home.

0 · step by milling process

1 · specifications of cnc milling machine

2 · introduction to cnc milling machine

3 · cnc milling machine types

4 · cnc milling machine description

5 · cnc milling explained

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

Sometimes it is necessary to junction or splice wires in home wiring electrical boxes. When splicing wires, an accessible electrical junction box box is necessary to enclose the spliced wires, thus the trade name is electrical enclosure. This list shows various electrical boxes and displays the box name and describes the typical application.

A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for .November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages .

Types of CNC Machines. CNC Milling Machine: Used for cutting, shaping, and drilling materials. CNC Lathe: Rotates the workpiece to perform various cutting and shaping operations. CNC Router: Works on larger pieces, often used for wood or plastic cutting. CNC Plasma Cutter: Cuts through metal using a plasma torch.

CNC milling machines fabricate intricate final parts with 3, 4, or 5 axes. The number of axes a CNC machine has determines its ability to handle complex, intricate parts and features. Manufacturers often employ a more .CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. As one type of CNC machining, it involves mounting the workpiece on a machine bed and .

Types of End Mills & Difference Between End Mill and Drill Bit | What is End Milling | CNCLATHING Introduction to Mini Milling Machine | Best Mini Milling Machine 2020 | CNCLATHING Top 5 Best 3D Printers 2021 – Best Budget, Beginner and Professional 3D Printer CNC Lathe Programming Guide & Tips – How to Make CNC Turning Program | CNCLATHING .

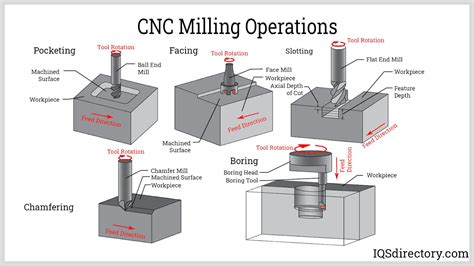

CNC milling machines can operate at high speeds and reduce the time it takes to make parts by more than half. That means you can fulfill larger orders in less time, increasing your productivity and reducing production costs. Another significant advantage of CNC milling is its precision and accuracy. These machines follow exact measurements and . Unlike a lathe machine – on which a workpiece spins and the cutting tool moves into it to create cylindrical shapes – the CNC milling machine employs end mills, dovetail cutters, face mills, and various other milling cutters to machine flat and irregular surfaces, including those that are concave or convex. CNC milling is a type of subtractive manufacturing process that integrates Computer Numerical Control (CNC) with milling machines to perform the desired machining operation. In this process, the workbed moves along the X, Y, and Z axis while the rotating tool plunges in and out of the workpiece surface.

What is CNC Milling Machine? CNC mill machine is an industrial tool that removes material from a stationary workpiece using rotating cutting tools to create precision parts. As a key piece of equipment in subtractive manufacturing, it can be operated .Milling CNC machines come in a wide array of sizes and types and can run on multiple axes. Plasma Cutters: The CNC plasma cutter uses a powerful laser to cut. Most plasma cutters cut programmed shapes out of sheet or plate.OUR NEW 1500MX CNC MILL. Our community asked, and we listened. Tormach customers love our capable yet affordable machines, easy-to-use PathPilot® control software, and US-based tech support. Your business has grown over the years and .

Manufactured in California, this CNC milling machine offers the largest cutting work area out of all the machines we’ve reviewed. Boasting a massive table size of 10” x 50”, with an x-axis capable of cutting up to 34”. The BM-3 offers a .CNC milling machine is commonly used in industrialized countries around the world, from low-end to high-end, and is used to produce the most modern mechanical processing equipment. In this article, we mainly introduce relevant information related to CNC milling. (The CNC machine mentioned below refers to CNC milling by default) What is CNC milling? Computer numerical control (CNC) milling is a typical machining process used to produce complex parts. This fabrication method gives high precision customized workpiece and cuts various materials like glass, plastic, metals and wood. Types of CNC milling machines

In 1994, the simple CNC milling machine KE-559 won the Machinery Development Award for promoting the development of small and medium-sized enterprises to automation in 1993. In 1995, the high-speed underwater wire EDM machine U32, U53, and the micron FF machine HYPER5 were successfully developed. The wire-cut EDM UPH-1 for fine machining has . A horizontal CNC milling machine (also known as a CNC mill) performing a milling operation on a metal part. What is the process? CNC milling, or computer numerical control milling, is a machining process that employs .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: . For CNC milling, the machine will hold the workpiece in a static position while the rotating cutting tool moves around it to shape it into the desired part. With CNC turning, the process is reversed, with the workpiece rotating as . What does a CNC Milling Machine do? A CNC milling machine makes intricate parts for several industries using subtractive machining technology. The milling machine cuts away at the workpiece and crafts the final piece via the 3, 4 or 5 axes. Depending on the number of axes the CNC milling machine has, the more complicated and intricate the final .The goal of modern CNC milling is to transform materials such as metal castings into finished, usable parts.That goal is only achievable by using incredibly precise CNC milling machines.. Computer software is the brains of a CNC (Computer Numerical Control) milling machine, controlling the machine and automating production to increase throughput with consistent quality.

The CNC milling machine is developed on the basis of the manual milling machine. The processing technology of the two is basically the same, and the structure is somewhat similar, but the CNC milling machine is an automatic processing machine controlled by the program, so its structure is also very.Different types of CNC boring machines. CNC boring machines are often grouped according to the number of axes on which they can work the material. For example, in the case of 4-axis CNC boring machines, each axis is identified by a specific letter. The X and Y axes represent the horizontal movement, the Z axis represents the vertical movement . The Components of a CNC Milling Machine. On a CNC machining center, the workpiece is mounted in a fixed position on a work table while the tool is moved around it. Embarking on a journey into the world of CNC milling requires familiarizing oneself with the primary components of the machine. Mainframe: Think of this as the backbone.

What is the CNC milling machine used for? CNC milling is a machining process suitable for producing high accuracy, high tolerance parts in prototype, one-off, and small to medium production runs. While parts are typically produced with tolerances ranging between +/- 0.001 in. to +/- 0.005 in., some milling machines can achieve tolerances of up to and greater than +/- . Most 4-axis CNC machines also have the capability to rotate the workpiece, known as the B-axis. This allows the machine to function both as a milling machine and a lathe. If you require drilling on the side of a part or on the surface of a . These machine tools can be ordinary machine tools or CNC milling machines. Use a rotating milling cutter as a cutting tool. Milling is generally performed on a milling machine or a boring machine, which is suitable for processing planes, grooves, various forming cavities (such as splines, gears and threads) and special curved surfaces of molds.

CNC milling is a versatile machining process that uses a rotating cutting tool to remove material from a stationary workpiece. It offers several distinct advantages and variations compared to other machining techniques. . Milling machines are well-suited for larger parts, while turning is typically used for smaller components. Complexity of . Traditional milling is often used for milling simple shapes/features like contours and slots, while CNC milling machines can handle complex shapes and features. Turning is used to process rotary parts, where the part is clamped on the machine spindle through a three-jaw chuck and rotated at high speed. Then, the turning tool is used to cut the .

step by milling process

specifications of cnc milling machine

introduction to cnc milling machine

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

what is cnc milling machine|cnc horizontal milling for dummies