macchine cnc additive manufacturing Hybrid CNC machines, also known as hybrid manufacturing systems or hybrid manufacturing machines, are advanced manufacturing systems that seamlessly integrate additive and subtractive manufacturing technologies . Provides weatherproof protection for horizontal and vertical installations using patented corner hinge. 15 Amp TRWR GFCI receptacle included with universal cover and one-gang weatherproof box. Cover is lockable for security. Die-cast construction and .

0 · cnc machining vs am

1 · cnc machining vs additive manufacturing

Sigma's weatherproof one-gang deep boxes provide an extra large junction for conduits and can house a single wired device such as a receptacle or switch. They can also be used to mount .

exterior pancake junction box

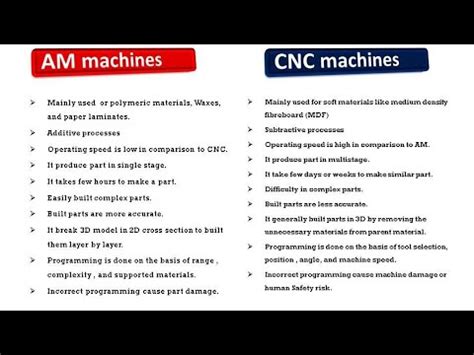

Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .

Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has . Hybrid CNC machines, also known as hybrid manufacturing systems or hybrid manufacturing machines, are advanced manufacturing systems that seamlessly integrate additive and subtractive manufacturing technologies . We offer cost effective and outstanding wire arc additive manufacturing (WAAM) solutions, from concept to end use, for large scale industrial metal components.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools.

exterior metal siding house

This company, known for machines that perform material removal through laser ablation, has been working with DMG Mori USA to develop a hybrid machine tool combining laser metal deposition for additive manufacturing with . All other structural elements of the machine are made by using additive manufacturing, specifically FDM (fused deposition modelling) technique. PLA material .Additive Manufacturing (AM) technology is a layer-by-layer processing technique that uses lasers or wire arcs to stack metal and create various 3D shapes. It enables the manufacturing of materials close to the final shape (near net shape), cladding with dissimilar metals, and repair of worn or chipped parts. Okuma America, a manufacturer of CNC machining centers, lathes and grinders, introduced its first multitasking CNC machine in North America in September. It employs hybrid manufacturing, which lets users .

Using CNC Machining to Create Precise 3D Printed Parts. Looking at the chart above, you will notice that one of the key differences between additive manufacturing and subtractive manufacturing is the surface finish and . CNC Engineering Inc. will now play a key role in the distribution, integration and support of the Meltio metal 3D additive manufacturing solutions for FANUC CNC and robotic systems in the U.S. market.

Cases for Adopting Additive Manufacturing Using your CNC Machine The Peter Parker proverb, “With great power comes great responsibility” can be applied to the emerging class of hybrid CNC machines. Within the last decade, augmented CNCs with additive, subtractive, and/or inspection capabilities have emerged.A clever combination: additive manufacturing and CNC machining. DMG MORI has been a successful player on the market since 2013, with its combination of laser deposition welding and machining on the LASERTEC DED hybrid series machines. The LASERTEC 65 DED for pure laser deposition welding acts as a supplement to an existing range of machining centres, while .Discover innovative hybrid additive manufacturing and CNC machines & learn about metal additive manufacturing and CNC machine 3D printers at Phillips Corporation. . Additive Manufacturing consists of any process that increases the mass of a part. Processes like manual welding can be considered Additive Manufacturing, but not 3D printing. . Metal parts produced through additive manufacturing almost invariably need machining as a follow-up step. Only the subtractive process can achieve the most narrow tolerances and smoothest finishes. Far from being opposite or competitive processes, additive manufacturing and CNC machining actually go together. They belong in the same machine.

The video shows how additive manufacturing works Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, and application. Bridging the gap between concepts and tangible .Phillips has taken the innovative laser metal deposition technology of Meltio and integrated it with the world-renowned Haas CNC vertical machining centers, bringing the best value additive hybrid machines to the market! Rather than purchasing a separate metal 3D printer, we install additive capabilities directly to your existing or new Haas machining center.

ADAM (Atomic Diffusion Additive Manufacturing) Technology – Safety and Quality! The Metal X printers are designed to use the ADAM (Atomic diffusion additive manufacturing) technology, an offshoot of the FFF technology. In this technological process, the metal powder is placed in a plastic binder and then extruded layer by layer.

Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools. Skip to main content; Skip to main navigation . The know-how from subtractive manufacturing as ideal entry into additive manufacturing! The know-how from subtractive manufacturing as ideal entry into additive manufacturing . Download Citation | Repurposing mainstream CNC machine tools for laser-based additive manufacturing | The advent of laser technology has been a key enabler for industrial 3D printing, known as . It is worthwhile to take stock of this. Again, additive manufacturing has advanced quickly, and part of that advance has been to advance machining — not just in a case like the adapter, but also more broadly in cases such as cutting tools made through 3D printing. How are machining and additive manufacturing now interacting with one another? Stand-alone machines, be they additive or subtractive in nature, can typically perform a single form of manufacturing. 3D printers can only perform additive manufacturing; CNC milling machines can only perform subtractive .

Titanium Powder for Additive Manufacturing in 2024. October 03, 2024. Report # AMR-TPAM2024-1024. 3DP/AM Market Insights: Q2 2024 . Okuma is known for being a manufacturer of CNC machines, but . In this episode of the AM Radio podcast, Robots & Autonomy Editor Julia Hider joins Additive Manufacturing’s Executive Editor Stephanie Hendrixson and Editor-in-Chief Peter Zelinski to discuss how robots and 3D printing . Hybrid Manufacturing Technologies on the role of hybrid additive manufacturing related to heat treating, multimaterial tooling and embedding sensing. . I posted a recent commentary about the continued advance of hybrid machine tools — machines that add 3D printing to CNC machining and can perform both in the same cycle. An early innovator .

Additive Manufacturing (AM) refers to the fabrication process of three-dimensional parts directly using the CAD model in layer-by-layer fashion [1, 2].Varieties of AM systems have been developed and are available on the market with the capability of processing various materials for part fabrication [3, 4].AM systems offer several advantages over the traditional . The eighth annual Additive Manufacturing Strategies (AMS 2025) networking business summit takes place February 4-6, 2025, in New York City. This 3D printing conference features keynote presentations and panel discussions surrounding growth, deployment and investment strategies in industrial additive manufacturing.

Siemens Xcelerator enables the scaling of additive manufacturing solutions: . Sinumerik CNC Robotics and Simove. VLM Robotics, builder of XXL manufacturing machines, offers innovative and turnkey solutions for the railway, shipbuilding, aerospace, and energy industries. At Formnext, VLM Robotics will debut its new model CALYPSO, a fully . The Phillips Additive Hybrid machine incorporates Meltio’s LMD laser head into Haas Automation’s VF, UMC, and TM Series CNC machine tool platforms to offer both subtractive and additive . a Nine technologies transforming the industrial product design (Industry & 4.0 Relate - & Why Manufacturers Should Care n.d., 2021). b Breakeven comparison Additive manufacturing Vs Conventional .

CNC vs 3D printing: Additive vs subtractive manufacturing. Unlike 3D printing, CNC is subtractive rather than additive. The CNC process starts with a larger block of material as the workpiece, and removes areas, like chipping away at marble – to get to the final model. 3D printers instead use additive manufacturing technologies. A CNC milling machine is a device that shapes a stock into a useful product using subtractive manufacturing which is controlled by a computer numeric control system (CNC). Subtractive manufacturing is a manufacturing method in which material is cut to desired shape and size using a controlled material removal process.

cnc machining vs am

Major Differences Between Additive Manufacturing and CNC Manufacturing. Though additive manufacturing and CNC machining enjoy wide application in rapid prototyping, they differ significantly in material usage, design flexibility, lead time, production volume, cost, and surface treatment. Material UsageFind out all of the information about the DMG MORI product: 5-axis CNC milling and additive manufacturing machine LASERTEC 65 DED hybrid. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

cnc machining vs additive manufacturing

Simply walk to your truck bed and open the carefully engineered lid to access your tools, materials, and more. Available in steel or aluminum diamond-plate toolbox designs, these units feature an ARMOR TUF® Powder Coat finish to ensure years of dependability.

macchine cnc additive manufacturing|cnc machining vs additive manufacturing